An Observable and Recordable Device for Separating Plant Extracts

A plant extract and separation device technology, applied in the field of plant extract separation, can solve the problems of inconvenient sample storage, inconvenient residue filtration, inconvenient residue crushing, etc., and achieve the effect of avoiding falling and losing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

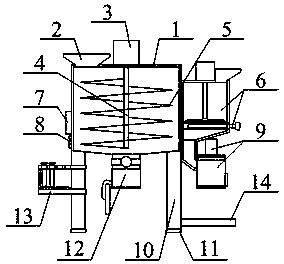

[0043] as attached figure 1 And attached figure 2 shown

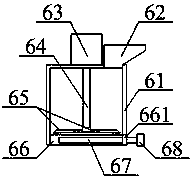

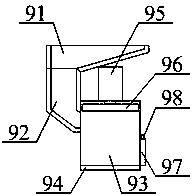

[0044] The present invention provides an observable and recordable plant extract separation device, comprising a stirring box 1, a hopper 2, a stirring motor 3, a stirring rod 4, a spiral stirring blade 5, an auxiliary crushing frame structure 6, a controller 7, and a control switch 8 , waste residue separation frame structure 9, support legs 10, anti-slip mat 11, discharge filter frame structure 12, sample storage frame structure 13 and storage plate 14, and the described hopper 2 is plugged into the upper left side of the mixing box 1; The stirring motor 3 bolts are installed on the middle and upper part of the stirring box 1; the stirring rod 4 is arranged at the inner middle position of the stirring box 1, and the bolts are installed on the lower output shaft of the stirring motor 3; the spiral stirring blades 5 is welded on the outside of the stirring rod 4; the auxiliary crushing frame structure 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com