Environment-friendly industrial waste gas purifying device

A technology for industrial waste gas and purification devices, which is applied in transportation and packaging, chemical instruments and methods, dispersed particle filtration, etc. Implementation, easy maintenance and maintenance, and the effect of avoiding air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

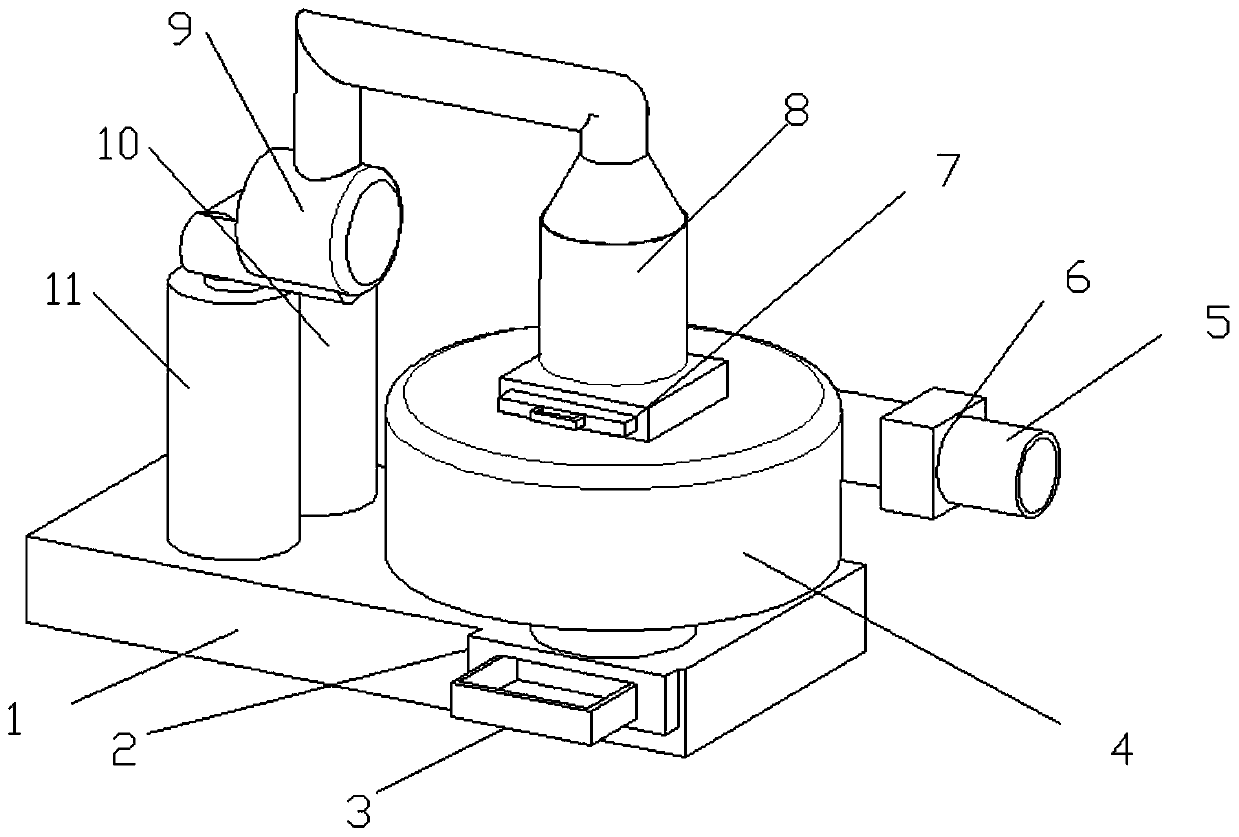

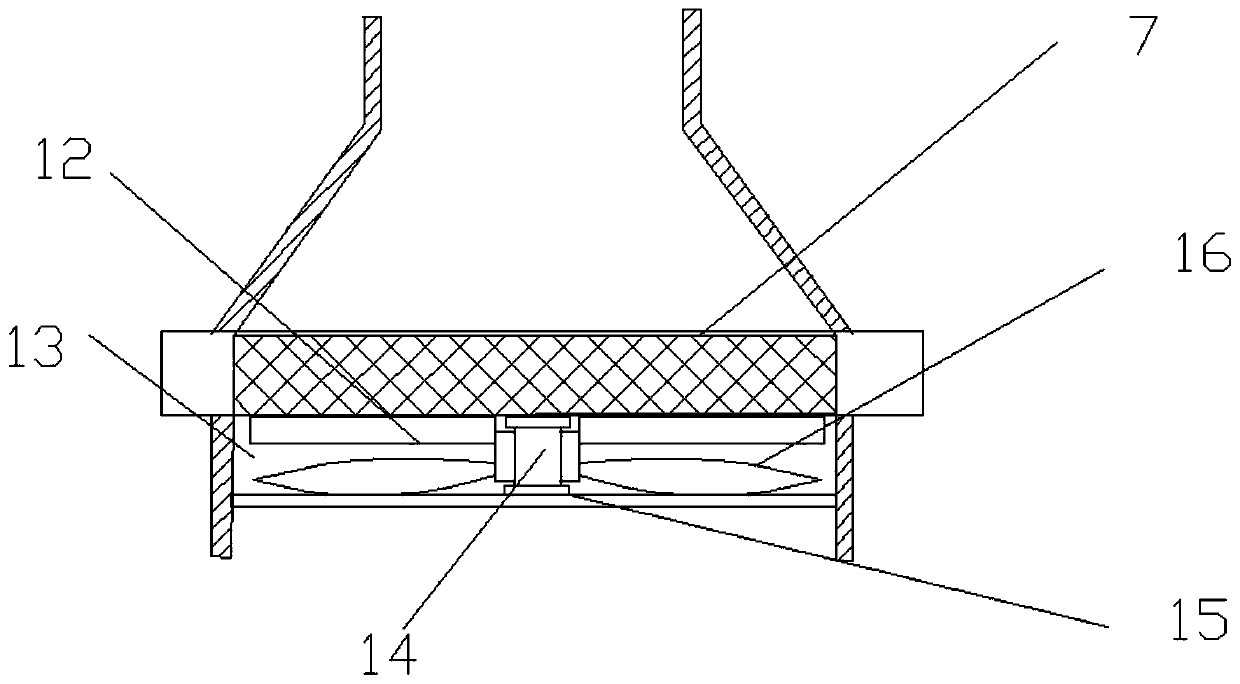

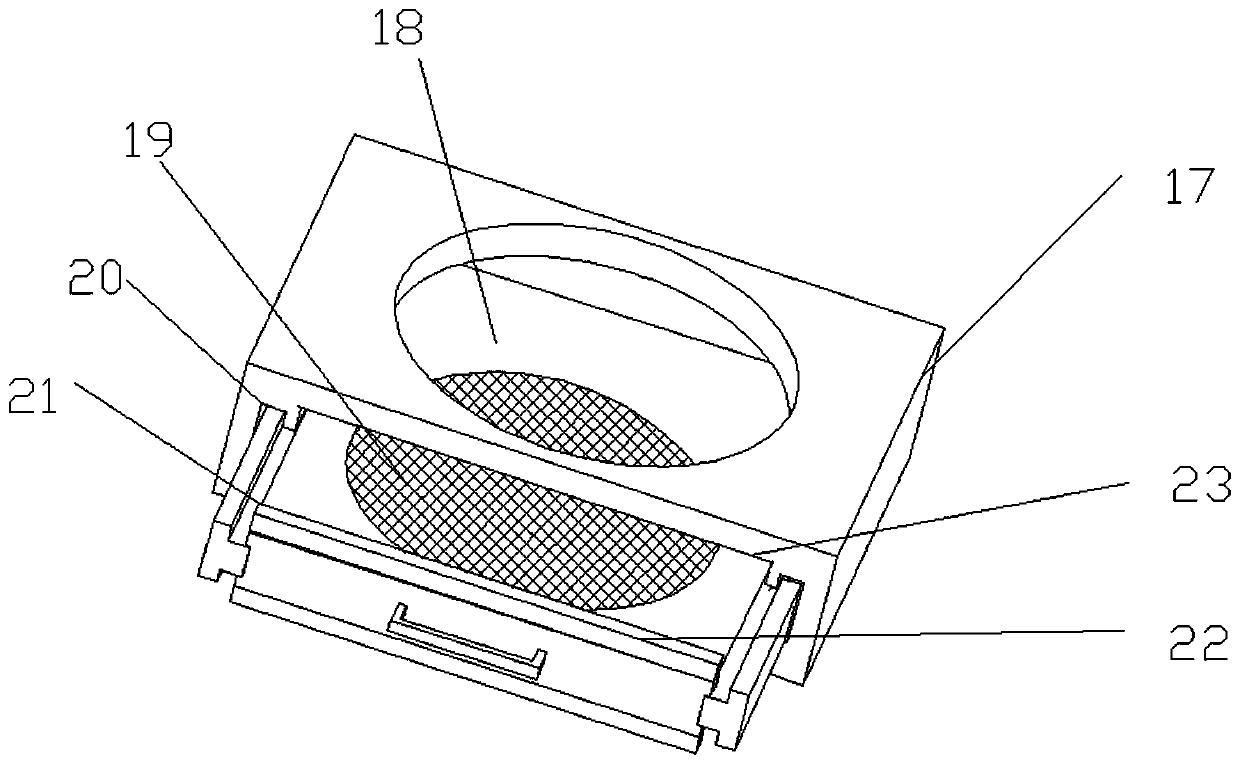

[0025] see Figure 1-4 , an environmental protection industrial waste gas purification device, including a workbench 1, a cyclone separator 4, an alkaline packed tower 10 and an acid tank 11. The upper surface of the workbench 1 is equipped with a cyclone separator 4, an alkaline packed tower 10 and an acid tank 11, and the side wall of the cyclone separator 4 is connected with an inlet pipe 5 tangentially, through which industrial waste gas enters the cyclone separator 4 internal separation. The intake pipe 5 is provided with a combustion box 6, and the industrial waste gas enters the combustion box 6 for combustion, and the combustible gas inside the industrial waste gas is burned inside the combustion box 6, so as to burn the industrial waste gas and reduce the harmful gas content. The top of cyclone separator 4 is communicated with outlet pipe 8, and the bottom of outlet pipe 8 is provided with filter assembly 7, and the bottom of filter assembly 7 is provided with cleani...

Embodiment 2

[0030] On the basis of Embodiment 1, the bottom of the shower spray head 24 is rotated to be provided with a second fan blade 25, and the micro-bubbles ejected from the shower spray head 24 drive the second fan blade 25 to rotate, and the micro-bubbles are ejected downwards and received The buoyancy force rises upwards, and the rising air bubbles are broken by the rotating second fan blade 25, which reduces the particle size of the air bubbles, increases the contact area, and makes the absorption more sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com