Drilling device for brake pad steel backing

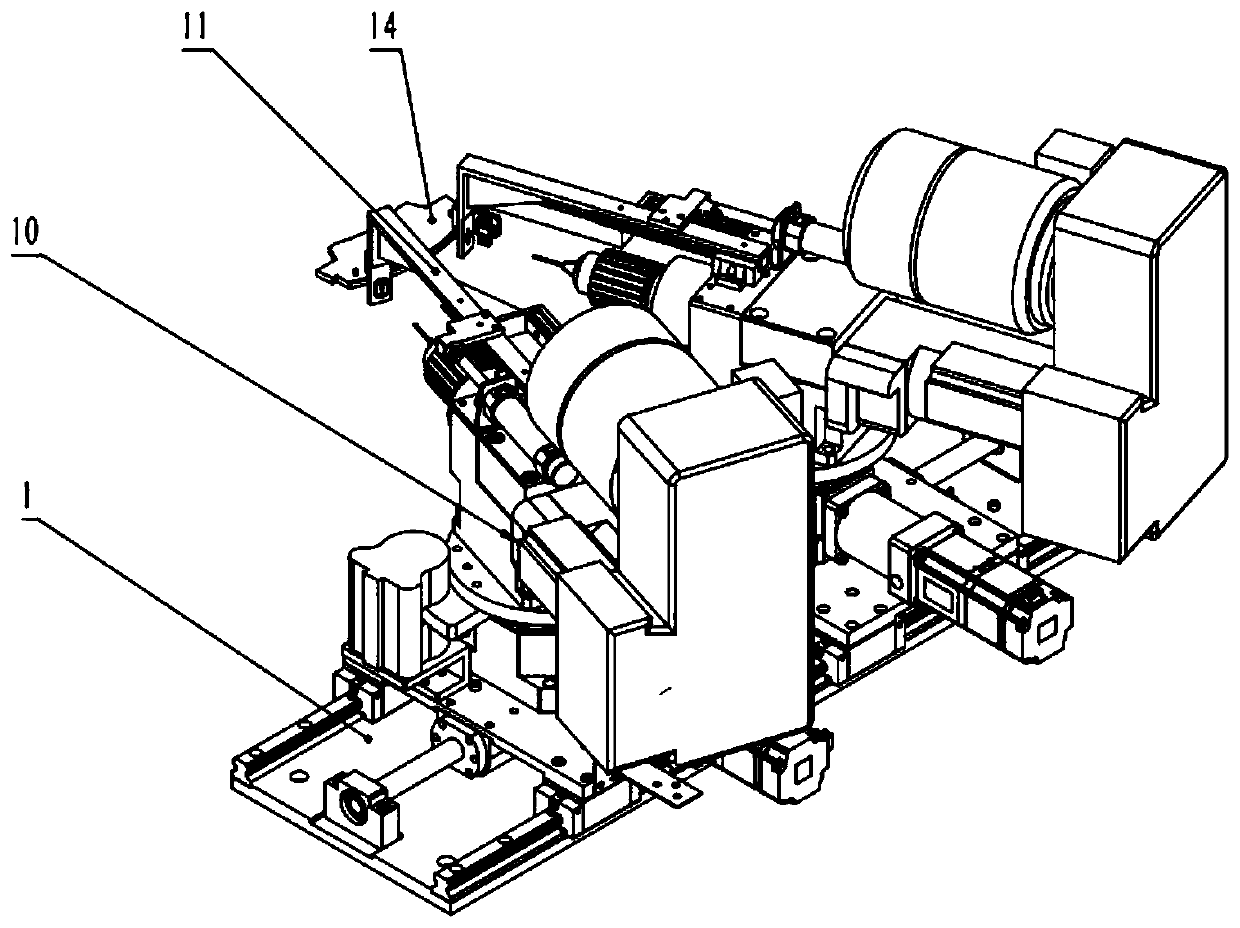

A drilling device and brake pad technology, applied in feeding devices, boring/drilling, automatic control devices, etc., can solve the problem of increasing capital investment, management costs and mold storage costs, and is not suitable for small batches and multi-variety modern manufacturing requirements , It is difficult to adapt to problems such as frequent product updates, to achieve the effect of saving debugging time, high degree of automation, and less processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

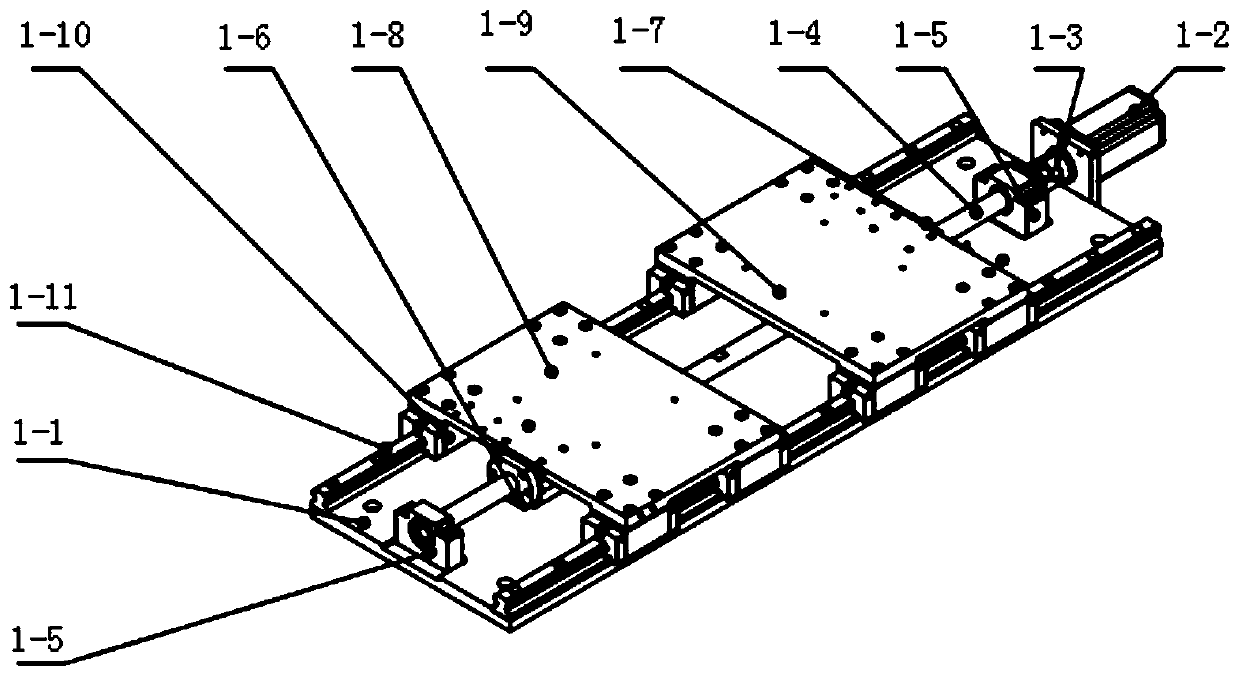

Method used

Image

Examples

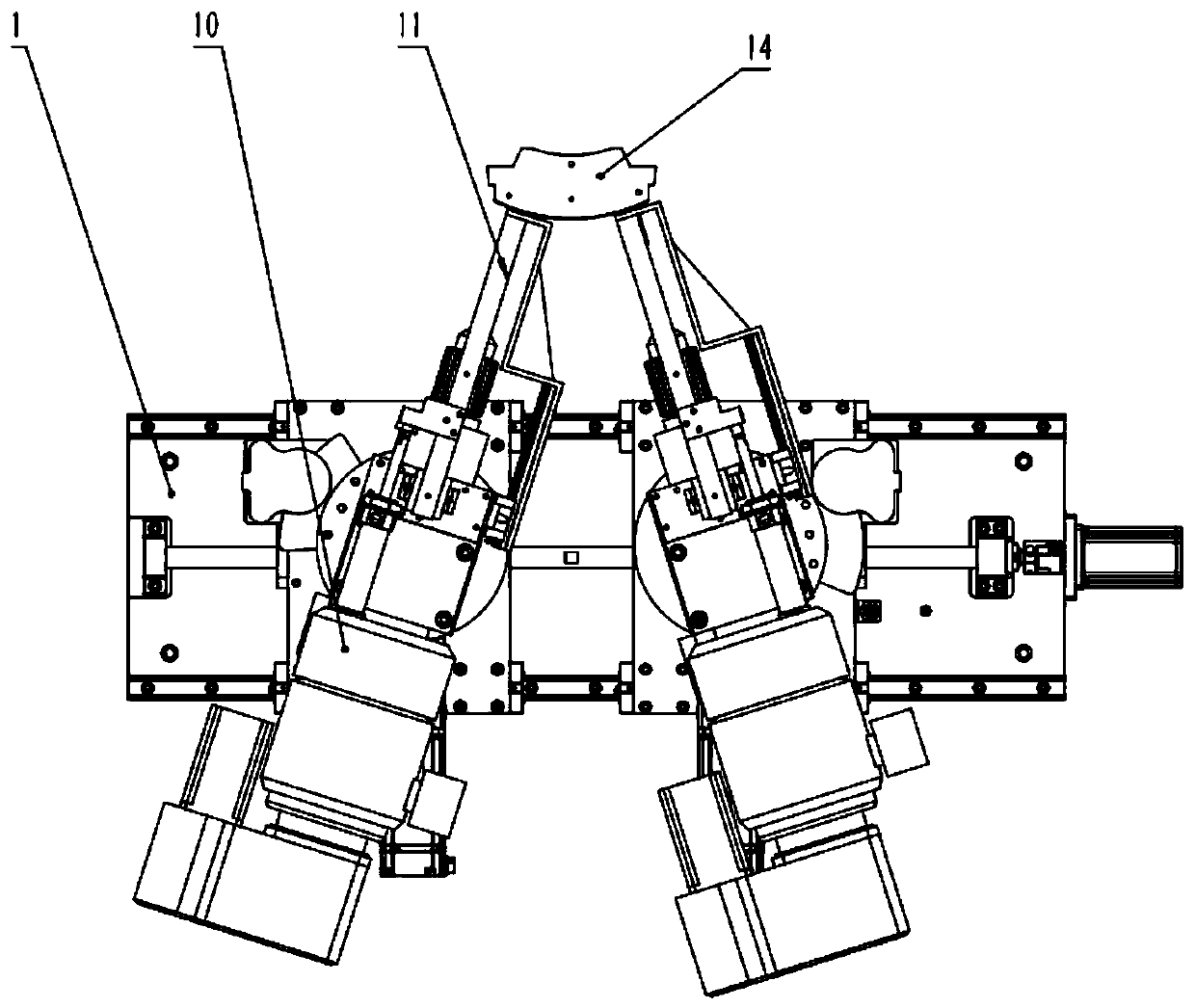

Embodiment 2

[0043] This embodiment discloses a working method of a brake pad steel back drilling device: the first driving mechanism drives the first drilling assembly and the second drilling assembly to move, so that the first drilling assembly and the second drilling assembly The symmetry line of the assembly coincides with the alignment axis of the steel back 14 of the brake pad to be drilled. The rotating platform drives the second drive mechanism and the drill bit to rotate to the preset position to realize the drilling angle positioning. The air pressure butterfly brake clamps the brake Tighten the disc to limit the further rotation of the second drive mechanism and the drill bit, the cylinder drives the clamping plate to move, the vertical plate stretches forward and contacts the arc surface of the steel back of the brake pad, and the steel back of the brake pad is fastened and fixed by the vertical plate. When the second driving mechanism starts to work, the drill bit stretches out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com