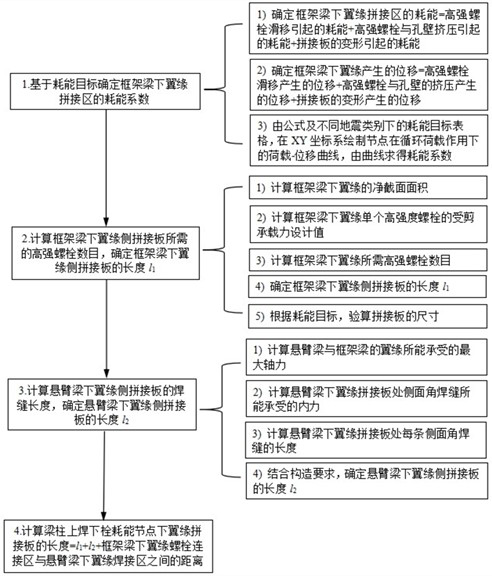

A method for determining the length of the spliced plate of the lower flange of the beam-column upper welded lower bolt joint based on the energy dissipation target

A splicing plate and flange technology, applied in the directions of architecture, geometric CAD, building structure, etc., can solve the problem of not considering the energy consumption of nodes, not clearly specifying the size of the splicing plate of the lower flange of the steel beam, and not specifying the inner flange of the node. Dimensions of cover, backing and web shears and their determination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

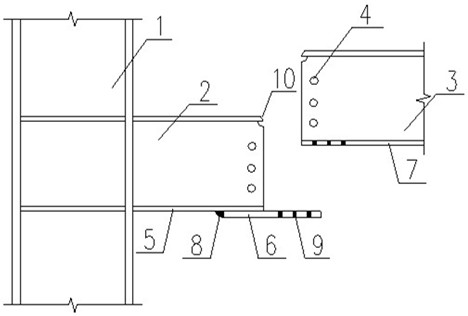

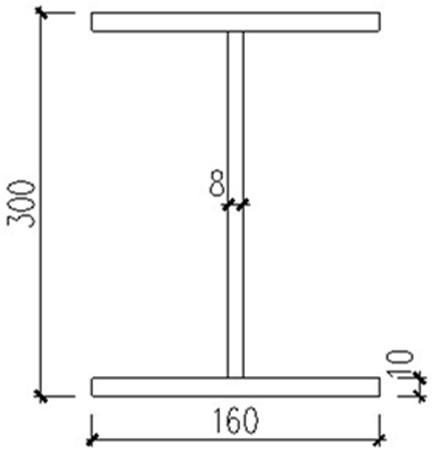

[0080] A beam-column upper-welding bolt joint, comprising a steel column 1, a cantilever beam 2, a frame beam 3, a web splicing bolt 4, a cantilever beam lower flange 5, a splicing plate 6, a frame beam lower flange 7, and a splicing plate 6 The fillet weld 8 connecting the lower flange of the cantilever beam 5, the high-strength bolt 9 connecting the splicing plate 6 and the lower flange of the frame beam 7, and the connecting weld 10 between the upper flange of the cantilever beam and the upper flange of the frame beam, among which, Q345B is used for beam and column steel Hot-rolled H-shaped steel, Q235 hot-rolled H-shaped steel is used for splicing plate 6, the cross-sectional dimensions of cantilever beam 2 and frame beam 3 are both HN300mm×160mm×8mm×10mm, and the cross-sectional dimension of column 1 is HW250mm×250mm×9mm×14mm; 10.9 grade M20 friction type high-strength bolts 9, the diameter of the bolt hole of the test piece is 21.5mm; the size of the web gusset plate is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com