Method for improving recovery by using foam flooding assisting nitrogen soaking in fault block oil reservoir

A technology of foam flooding and recovery, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of non-regeneration of foam, low degree of periodic recovery, and reduced concentration of surfactants, etc., and achieve reduction The formation of channeling channels, the effect of improving the effective action period and expanding the longitudinal action radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

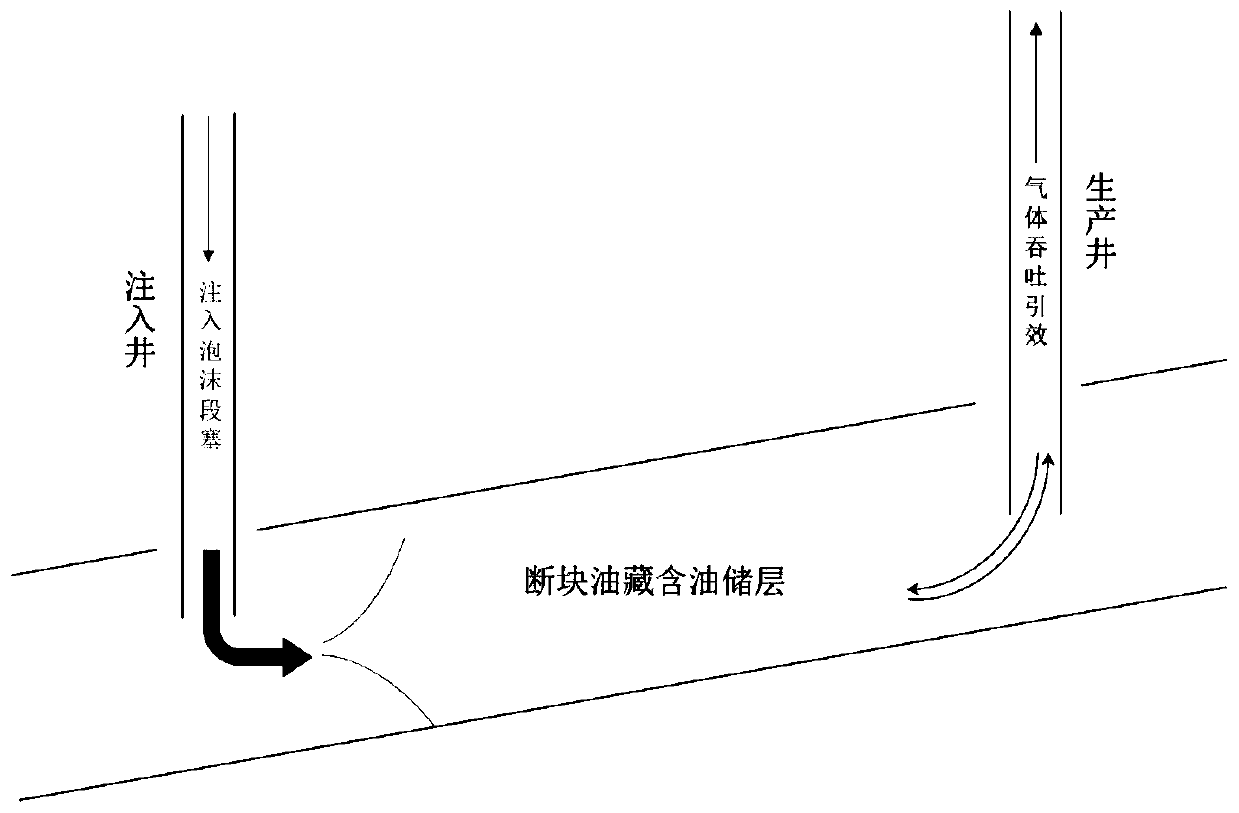

[0054] Such as figure 1 As shown, the principle description is as follows:

[0055] In conjunction with the method described in the present invention and the specific technical contents of the present embodiment, it can be known that:

[0056] Foam slugs are injected into the injection well, the displacement profile is adjusted, and the piston pushes the crude oil near the injection well to the direction of the production well. Poor, but its effect as an auxiliary follow-up nitrogen huff and puff still exists, which means that it supplements the formation energy and adjusts the underground flow field; During the process, the nitrogen gas is in full contact with the foaming fluid, and the blowout of the production well provides power conditions, and the generated foam is also conducive to improving the production increase effect of nitrogen gas huff and puff.

[0057] A method for enhancing recovery by foam flooding assisted nitrogen huff and puff in a fault-block reservoir, ...

experiment example

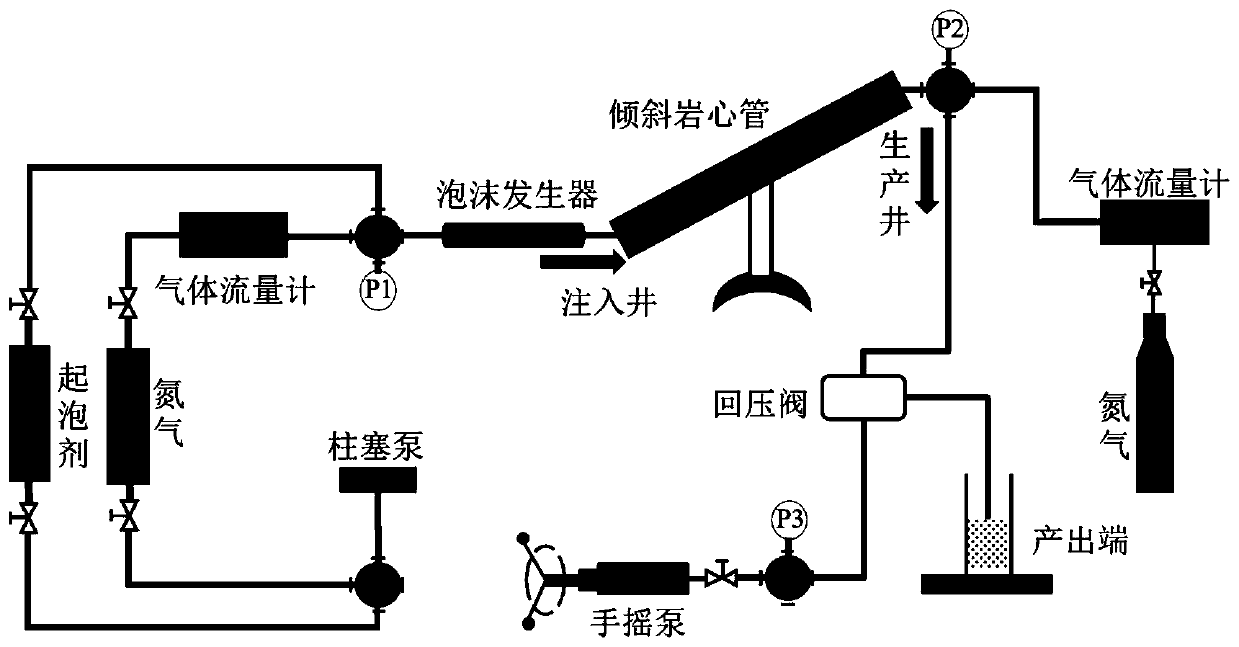

[0078] In conjunction with technical scheme described in the present invention, carry out laboratory experiment, flow process is as follows figure 2 As shown, the experiment was carried out at a constant temperature, simulating the actual reservoir environment.

[0079] Regarding the laboratory experiment, the simulation instructions for the oil layer thickness, oil-bearing area, and reservoir depth:

[0080] In laboratory conditions, the experimental parameters are based on the similarity criterion of the physical simulation experiment. According to the three methods of the traditional similarity criterion, the similarity criterion based on the experimental time and the similarity criterion based on the PV number, combined with the experience of the one-dimensional physical simulation experiment. customized.

[0081] The thickness of the oil layer and the oil-bearing area correspond to the oil-containing volume in the experimental conditions. After scaling them in equal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com