Water-spraying particle separator in serpentine pipe for adsorbing diesel engine exhaust

A particle separator and helical tube technology, applied in the directions of machines/engines, mechanical equipment, gas passages, etc., can solve the problems of high cost, poor adsorption effect, complicated after-machine treatment equipment, etc., and achieve low cost, simple structure, The effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

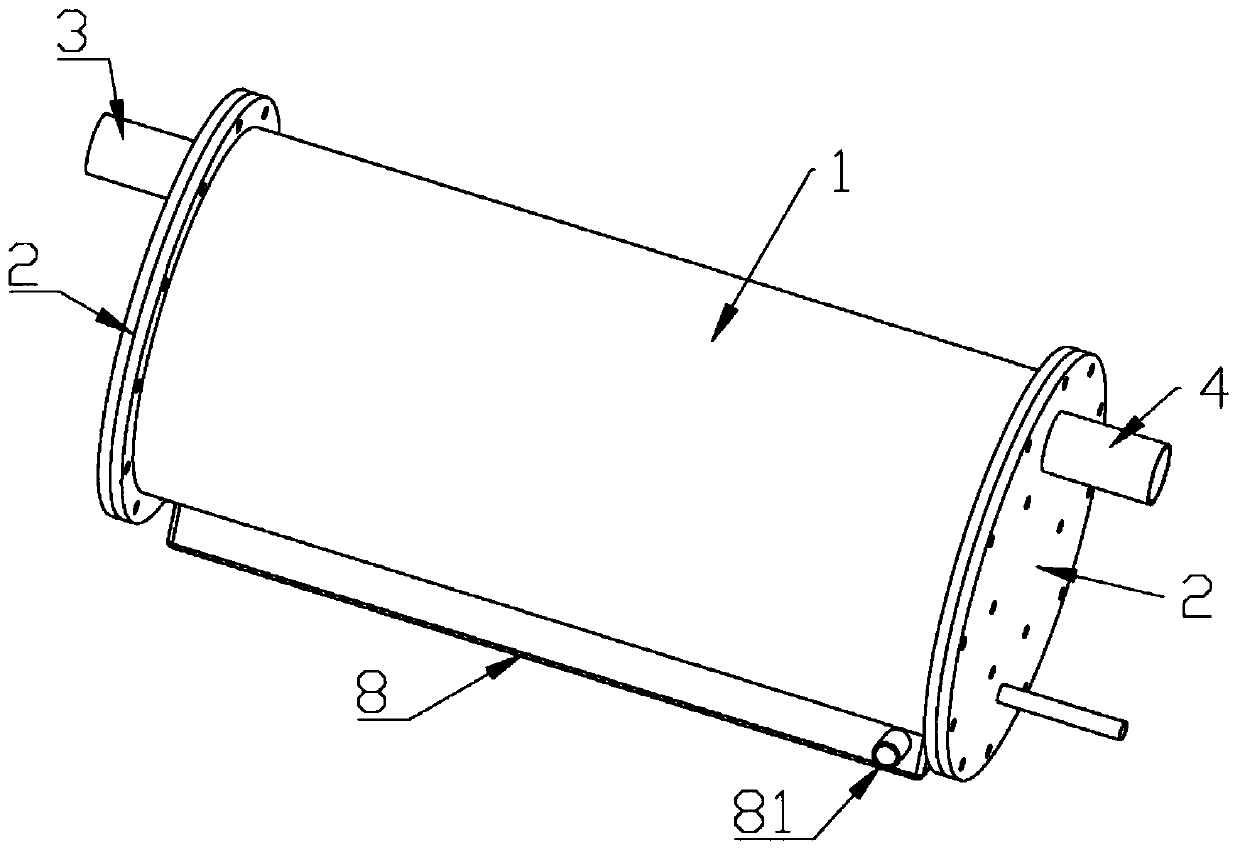

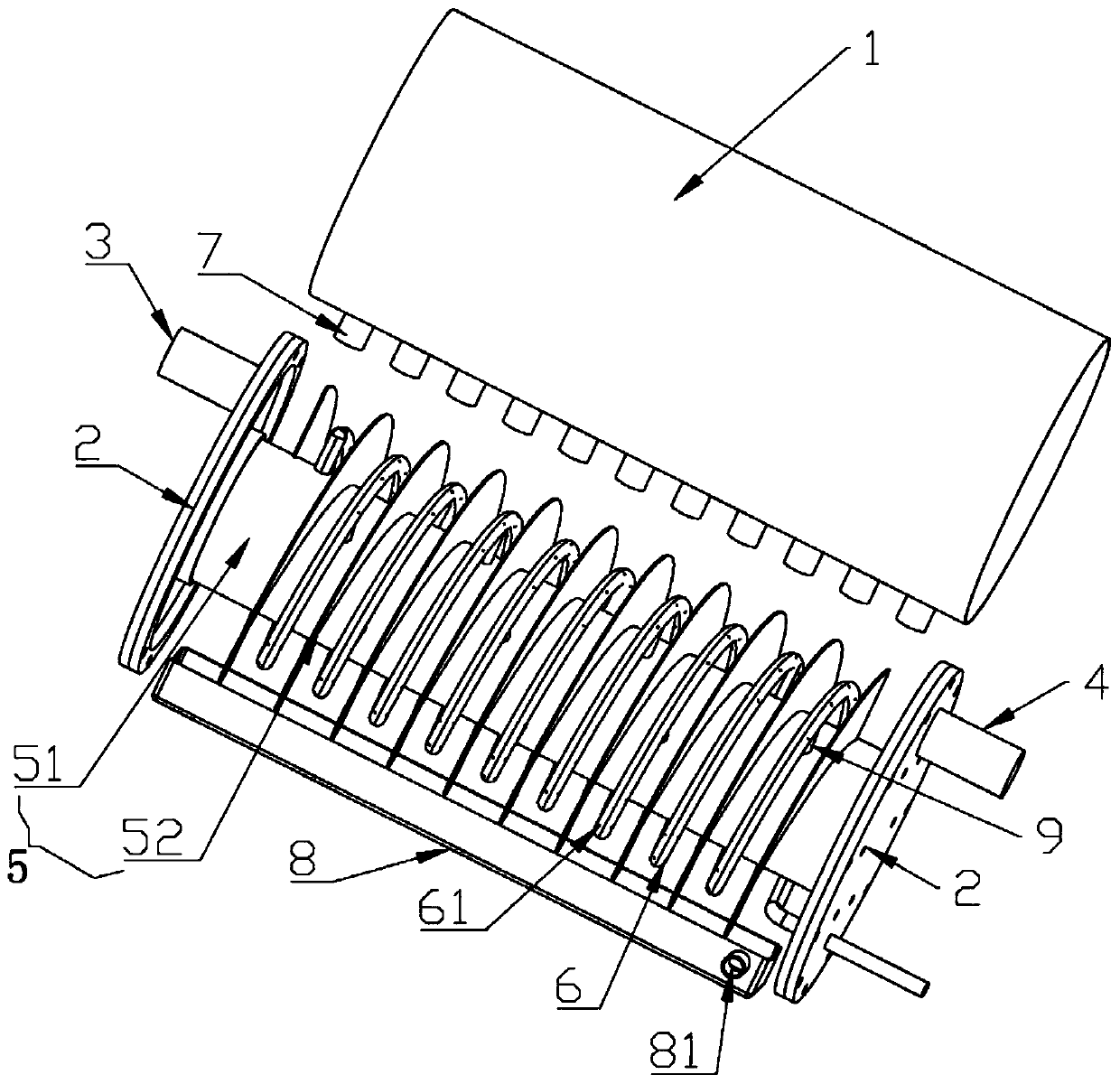

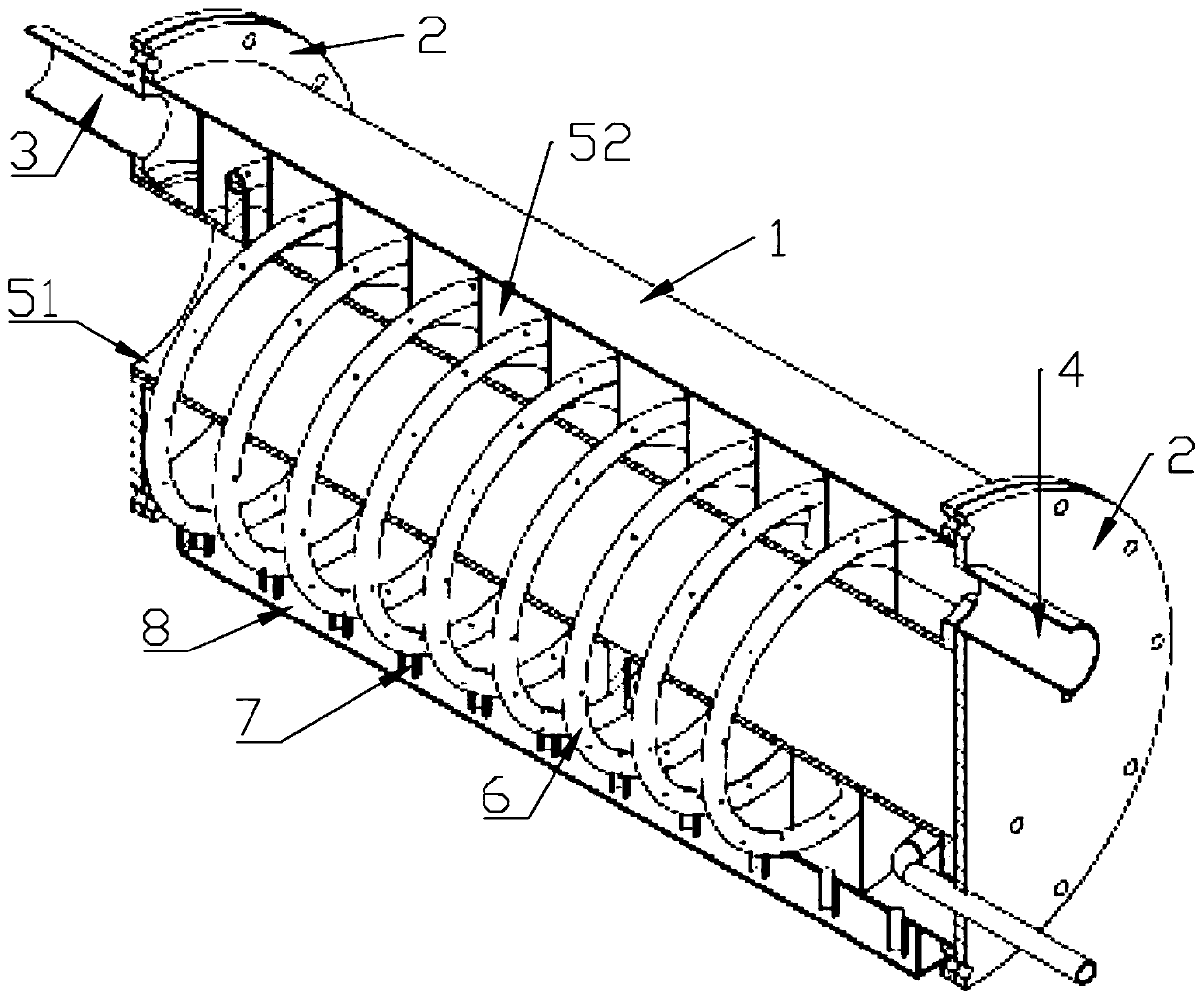

[0022] A kind of particle separator of water spraying type adsorption diesel engine exhaust in the spiral tube of the present embodiment, such as Figure 1 to Figure 3 As shown, it includes a cylinder 1, two end plates 2, a spiral tube 5 and a spiral elbow 6. The cylinder 1 and the end plates 2 together form an inner cavity, and the two end plates 2 are respectively provided with a connecting cavity. Air inlet 3 and air outlet 4. The spiral tube 5 includes a tube body 51 and helical fins 52. The two ends of the tube body 51 are respectively fixed on the corresponding end plates 2. The fins 52 are fixed on the outside of the tube body 51, and the outer edges of the fins 52 just touch The inner wall of the cylinder body 1 is closed, so that the cylinder body 1 and the spiral tube 5 together form a helical adsorption channel. Elbow 6 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com