Seabed hydrocarbon natural gas flow measurement apparatus, system, and method

A flow measurement device, natural gas technology, applied in fixed measurement chambers and other directions, can solve problems such as large errors in flow measurement results, and achieve the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

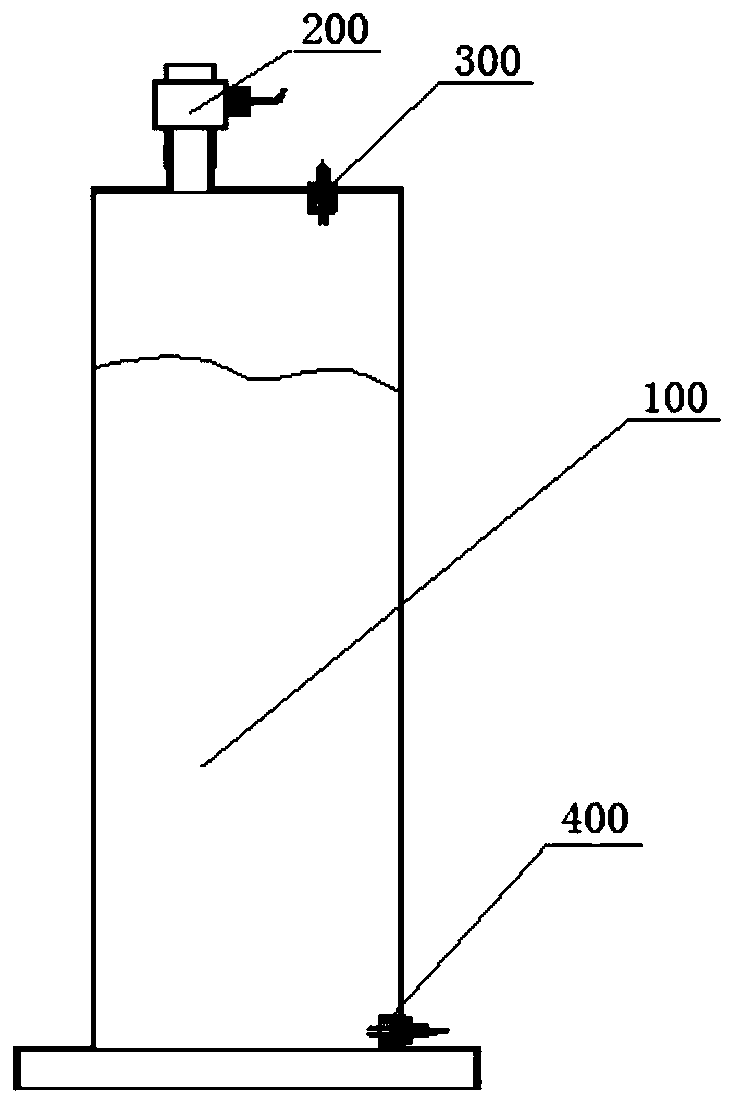

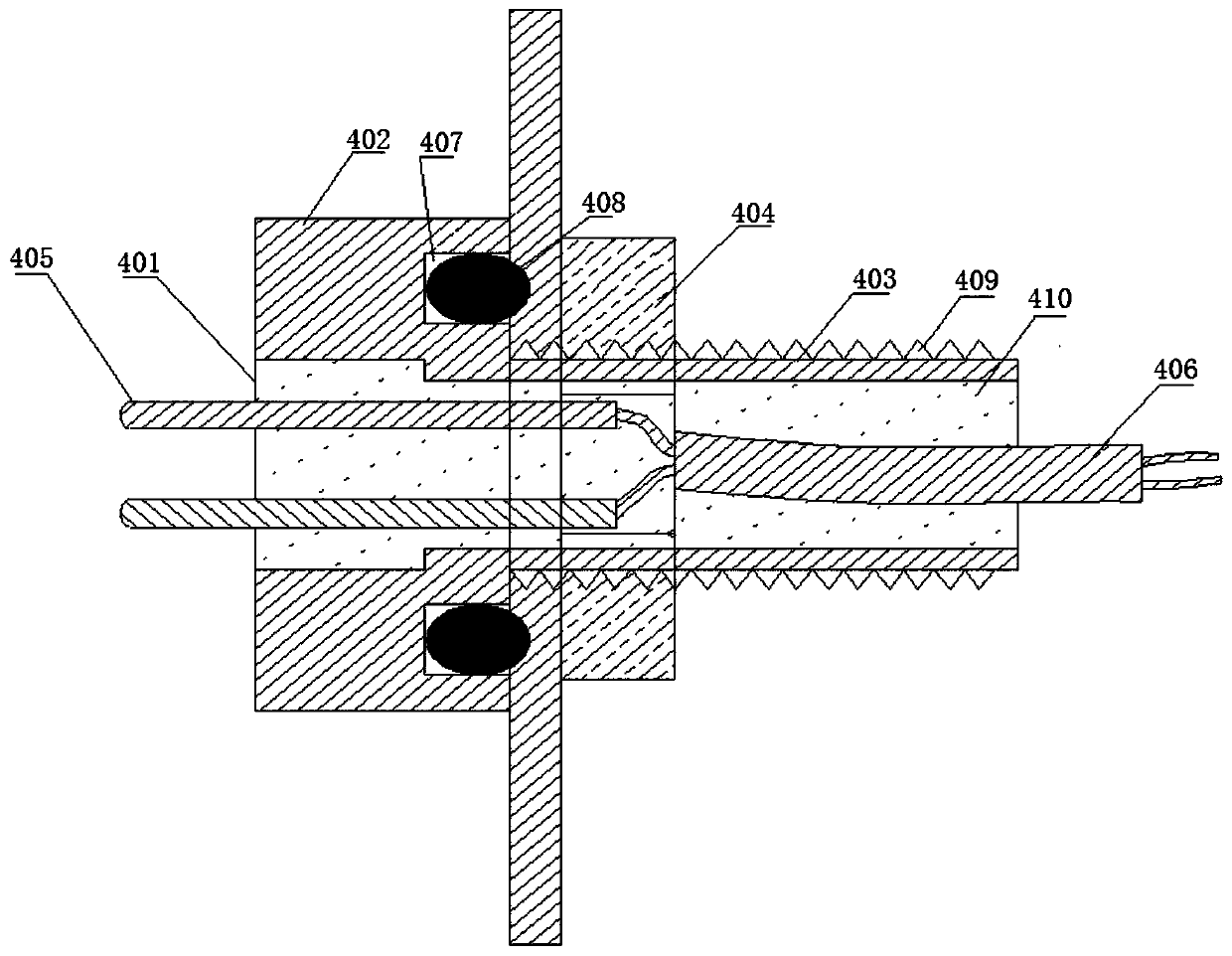

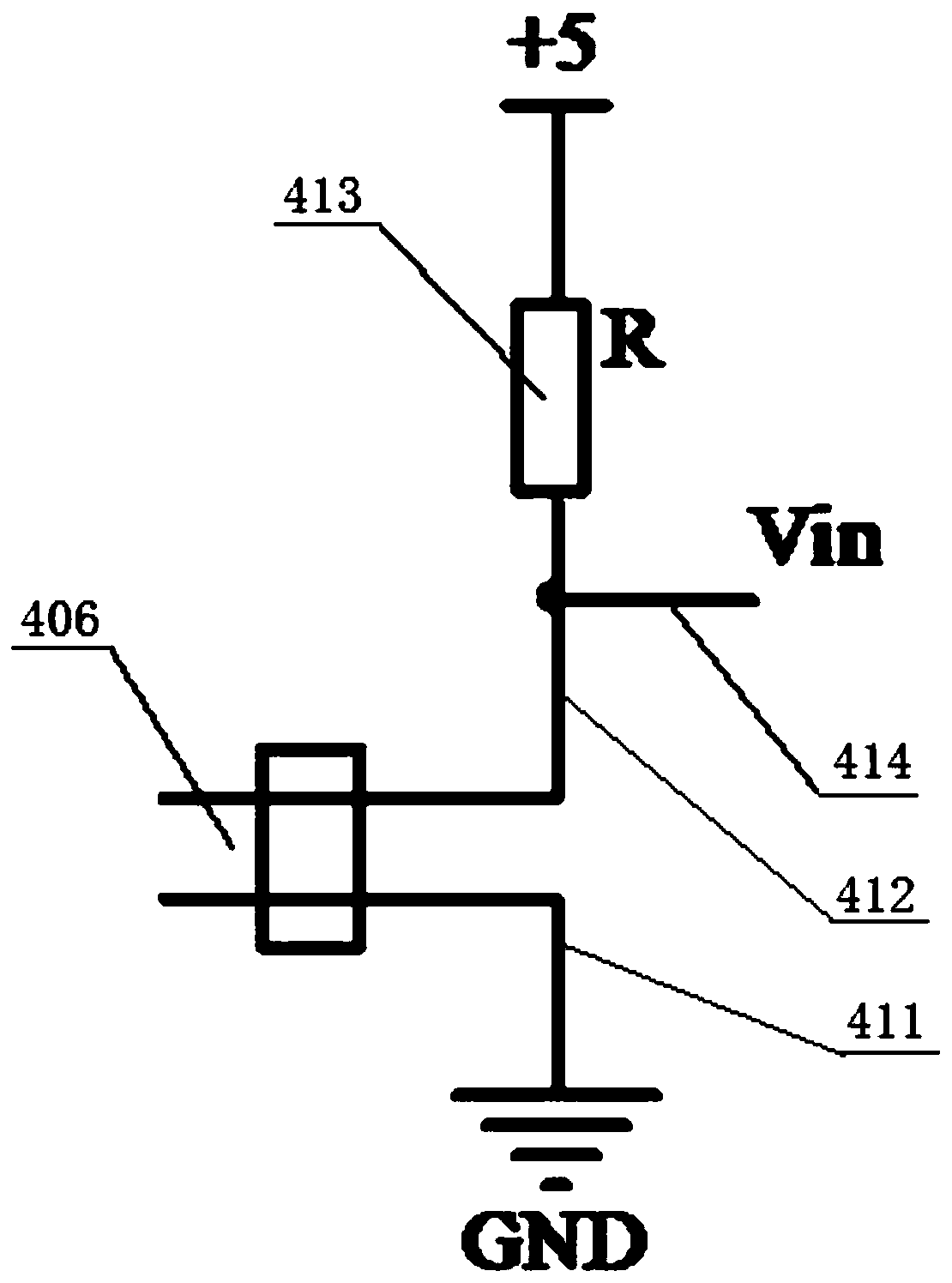

[0035] Such as Figure 1 to Figure 3 Shown is an embodiment of the subsea hydrocarbon natural gas flow measurement device of the present invention, including a gas collection chamber 100 connected to the bubble collection device, a valve 200 communicated with the gas collection chamber 100 and used to indicate the liquid level in the gas collection chamber 100 The first liquid level electrode 300 and the second liquid level electrode 400 are changed, the valve 200 is arranged on the top of the gas collection chamber 100, the first liquid level electrode 300 is arranged on the top of the gas collection chamber 100, the second liquid level The electrode 400 is disposed at the bottom of the gas collection chamber 100, and the gas collection chamber 100 is provided with a drain. The valve 200 in this embodiment is a pressure-resistant underwater solenoid valve, and the first liquid level electrode 300 and the second liquid level electrode 400 are liquid level electrodes in a deep ...

Embodiment 2

[0046] Such as Figure 4 Shown is an embodiment of the subsea hydrocarbon natural gas flow measurement system of the present invention, including a detection control chip 500 and a subsea hydrocarbon natural gas flow measurement device as described in Embodiment 1, the first liquid level electrode 300, the second liquid level electrode The bit electrode 400 is connected to the input end of the detection control chip 500 , the valve 200 is connected to the output end of the detection control chip 500 , and the detection control chip 500 is connected to the storage module 600 .

[0047] During the implementation of this embodiment, the detection control chip 500 receives the liquid level signal detected by the first liquid level electrode 300 and the second liquid level electrode 400, and sends a control signal to the valve 200 according to the received liquid level signal, and operates the valve 200 The number of times and action time are stored in the storage module 600, and t...

Embodiment 3

[0049] This embodiment is an embodiment of the seabed hydrocarbon natural gas flow measurement method of the present invention, comprising the following steps:

[0050] S10. The natural gas leaking upwards enters the gas collection chamber 100 through the bubble collection device, and the seawater in the gas collection chamber 100 is discharged downward;

[0051] S20. When the liquid level of seawater in step S10 drops to the position of the second liquid level electrode 400, the control opens the valve 200, the gas in the gas collection chamber 100 is emptied, and the seawater liquid level in the gas collection chamber 100 rises to the second level at the same time. a position of the liquid level electrode 300;

[0052] S30. The control valve 200 is closed, and the natural gas leaking upward enters the gas collection device again for the next gas collection;

[0053] S40. Steps S10-S30 are looped, the valve 200 is opened once and the data recorder records once, and the time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com