Photosensitive resin composition, dry film, and method for manufacturing printed circuit board

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of unevenness, uneven stripes, inability to uniformly coat resist material coating, etc. short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

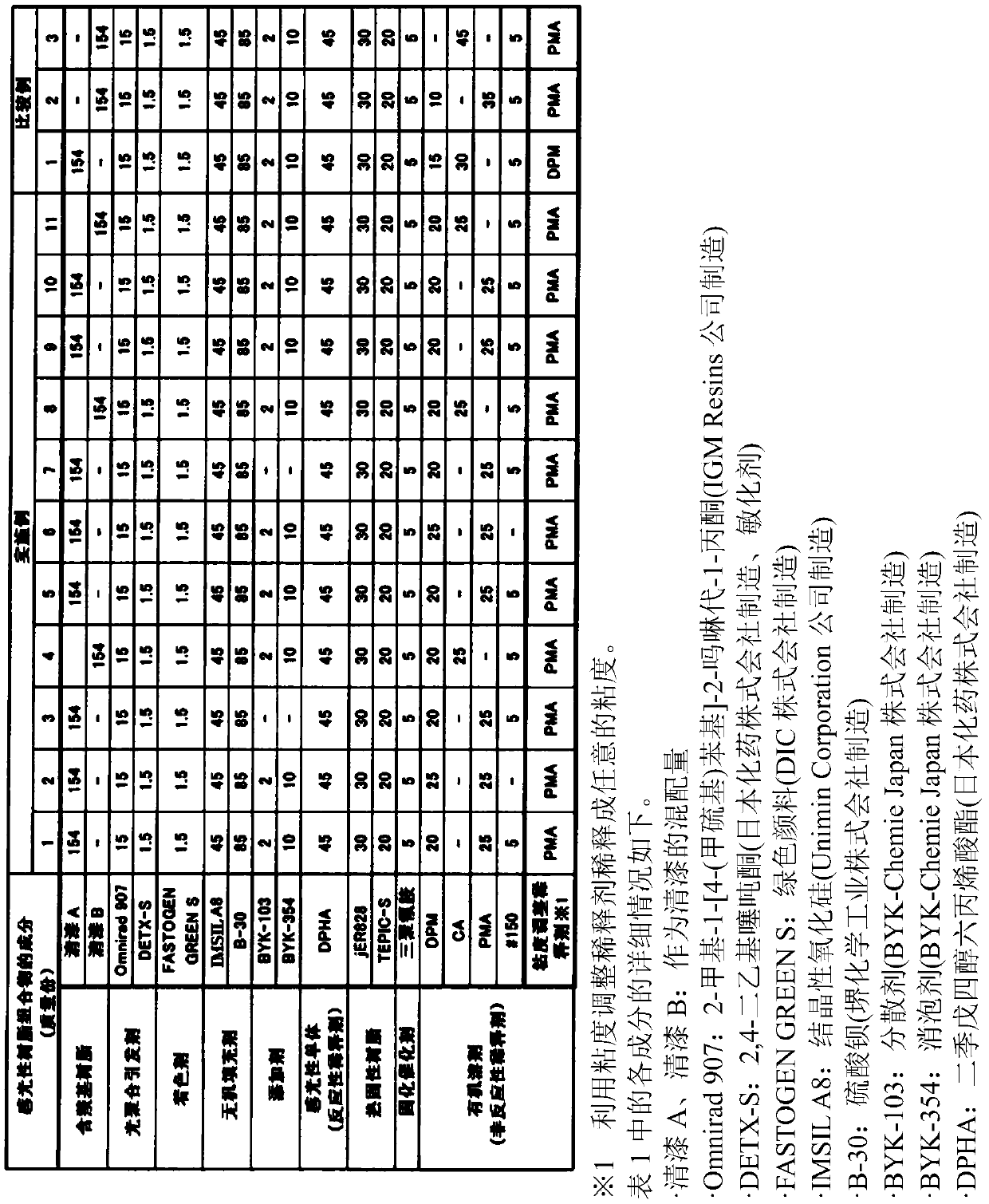

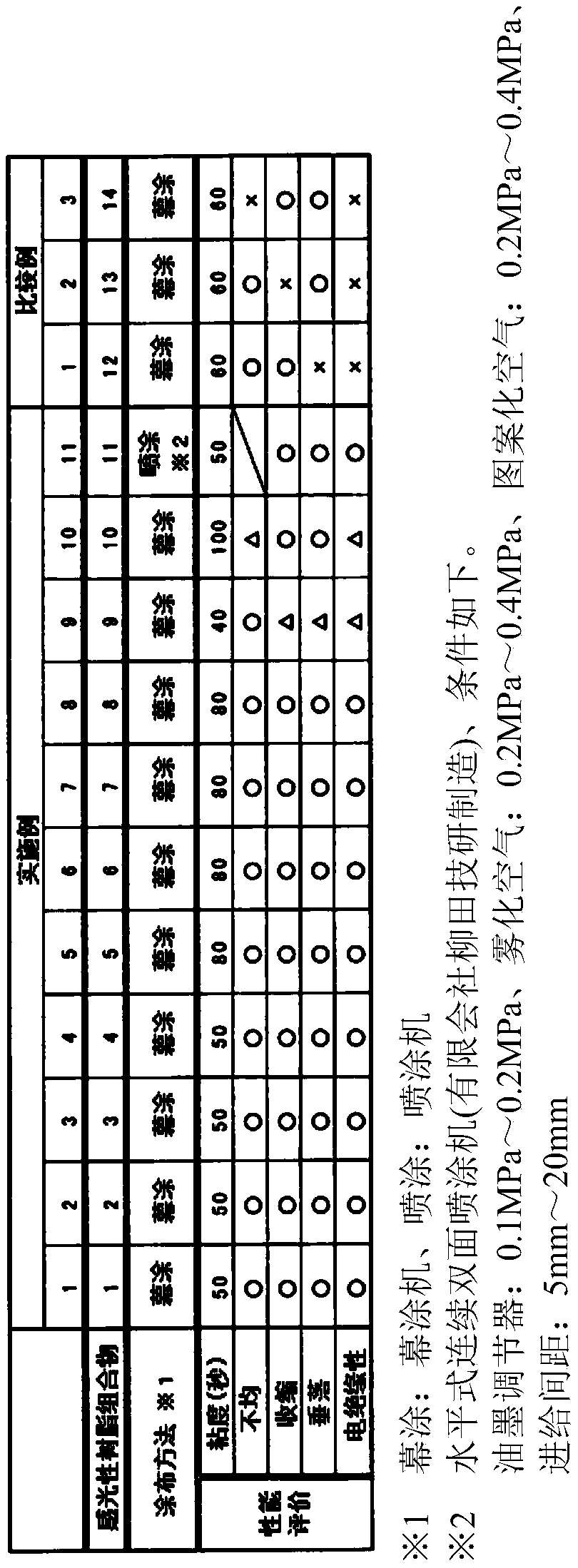

[0103] According to the ratio (parts by mass) shown in Table 1, the varnish A prepared above, photopolymerization initiator, coloring agent, inorganic filler, additive, photosensitive monomer (reactive diluent), thermosetting resin, curing catalyst and The organic solvent (non-reactive diluent) was pre-mixed with a mixer, kneaded with a three-roll mill, and the viscosity was adjusted with PMA to prepare a photosensitive resin composition (solder resist composition) 1 . Regarding the contents of the three organic solvents (dipropylene glycol monomethyl ether (hereinafter also referred to as DPM), CA, and PMA) in the photosensitive resin composition 1, DPM is 20 mass parts with respect to 100 mass parts of carboxyl group-containing resin in solid content parts, CA is 54 parts by mass, and PMA is 140 parts by mass.

Embodiment 2

[0105] Except having changed the compounding ratio of each component as shown in Table 1, it carried out similarly to Example 1, and prepared the photosensitive resin composition 2. The contents of the three organic solvents (DPM, CA, PMA) in the photosensitive resin composition 2 are 25 parts by mass for DPM, 54 parts by mass for CA, and 140 parts by mass for PMA with respect to 100 parts by mass of the carboxyl group-containing resin in the solid content. parts by mass.

Embodiment 3

[0107] Except having changed the compounding ratio of each component as shown in Table 1, it carried out similarly to Example 1, and prepared the photosensitive resin composition 3. The contents of the three organic solvents (DPM, CA, PMA) in the photosensitive resin composition 3 are 20 parts by mass for DPM, 54 parts by mass for CA, and 140 parts by mass for PMA with respect to 100 parts by mass of the carboxyl group-containing resin in the solid content. parts by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com