Patents

Literature

34 results about "DIETHYLENE GLYCOL MONOETHYL ETHER ACETATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylene glycol monoethyl ether acetate contains chromophores that absorb at wavelengths >290 nm and therefore may be susceptible to direct photolysis by sunlight. If released to soil, diethylene glycol monoethyl ether acetate is expected to have very high mobility based upon an estimated Koc of 10.

Halogen-free low temperature solidified silver paste and preparation method thereof

InactiveCN101950596AReduce pollutionSuitable process conditionsNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingEthylene glycol monoethyl ether acetate

The invention provides a halogen-free low temperature solidified silver paste, which comprises the following raw materials in percentage by mass: 40 to 50 percent of conductive powder, 37 to 46 percent of solvents, 8 to 20 percent of high polymer resin and 1 to 3 percent of additives, wherein the conductive powder is a mixture of flake silver powder and silver coated nickel powder; the solvent is one or more of DBE, diethylene glycol monoethyl ether acetate, propylene glycol methyl ether acetate and ethylene glycol monoethyl ether acetate; the high polymer resin is one or more of polyester resins and polyurethane resins; and the additives comprise one or more of coupling agents, thickening agents and leveling agents. In the halogen-free low temperature solidified silver paste of the invention, the conductive powder is successfully used for replacing silver powder, which not only can reduce the cost, but also satisfies European safety standards, and reduces environment pollution.

Owner:IRICO

Low-temperature solidification electric-conduction slurry

InactiveCN101699566AMeet the needs of useLow costConductive materialNon-conductive material with dispersed conductive materialDIETHYLENE GLYCOL MONOETHYL ETHER ACETATEEthylcarbitol

The invention provides a low-temperature solidification electric-conduction slurry with less than 50 percent of silver content; the electric-conduction slurry comprises the following raw materials by mass percent: 45-50 percent of electric-conduction silver powder, 40-45 percent of solvent, 7-15 percent of macromolecule resin and 0-5 percent of additives; the electric-conduction silver powder is silver strip powder and silver ball powder, the solvent is more than one or two kinds of DBE, diethylene glycol monoethyl ether acetate and butyl cellosolve acetate, the macromolecule resin adopts one or two kinds of chloride-vinyl acetate resin and polyester resin, and the additives are one or two kinds coupling agents or flatting agents; in the invention, the strict using requirements of customers on resistance can be met while reducing the cost; in addition, the low-temperature solidification electric-conduction slurry has less than 50 percent of silver content, and the square resistance can reach 13megohm / square.

Owner:IRICO

Low-temperature cured conductive paste with ultra-low silver content and preparation method thereof

InactiveCN101950595AMeet the resistanceMeet needsNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingSuspending Agents

The invention provides a low-temperature cured conductive paste with ultra-low silver content, which is prepared by the following components in percentage by weight: 45-50% of conductive powder, 40-45% of solvent, 10-15% of macromolecule resin, and 0-5% of additive, wherein the conductive powder is a mixture of 35-40% of silver flake powder, 3-5% of conductive ferrophosphorus alloyed powder and 5-7% of conductive nickel powder accounting for the conductive paste in percentage by weight; the solvent is one of dibasic ester (DBE), diethylene glycol monoethyl ether acetate or 2-Butoxyethyl acetate; the macromolecule resin is hydroxyl-modified vinyl resin or polyester resin; and the additive comprises one or more of coupling agent, suspending agent, thickening agent and flatting agent. The silver content of the conductive paste of the invention is below 40%, and demands of customers on resistance and other aspects are met while reducing cost.

Owner:IRICO

Low-temperature conductive copper paste and preparation method thereof

InactiveCN109979686AImprove conductivityHigh viscosityNon-conductive material with dispersed conductive materialCable/conductor manufactureDIETHYLENE GLYCOL MONOETHYL ETHER ACETATEPolyester resin

The invention relates to a preparation method of low-temperature conductive copper paste. The preparation method is implemented by the steps of (1) preparing a high-molecular polyester resin carrier:adding 30-50% of solid high-molecular polyester resin into 50-70% of a diethylene glycol monoethyl ether acetate solvent; and (2) preparing the copper paste: taking silver-coated copper powder with the average particle size of 5-15 microns and the proper radius-thickness ratio, adding 45-65% of the silver-coated copper powder and 33-53% of the high-molecular polyester resin carrier prepared in thestep (1) into a high-speed dispersing machine for carrying out dispersion to obtain a preliminarily uniform primary carrier, pouring the carrier into a three-roller machine for carrying out grindingand dispersion to obtain a secondary carrier, adding the secondary carrier, 1.6-2% of a closed isocyanate curing agent and 0.1-0.5% of a high-molecular dispersing agent into a planetary stirrer, carrying out vacuumizing and removing bubbles to obtain the conductive copper paste. The preparation method is reasonable in design; various performances such as the conductivity, viscosity, printability,tension and the like of the prepared low-temperature conductive copper paste are excellent; and the requirements of circuit board printing can be met.

Owner:东莞市银屏电子科技有限公司

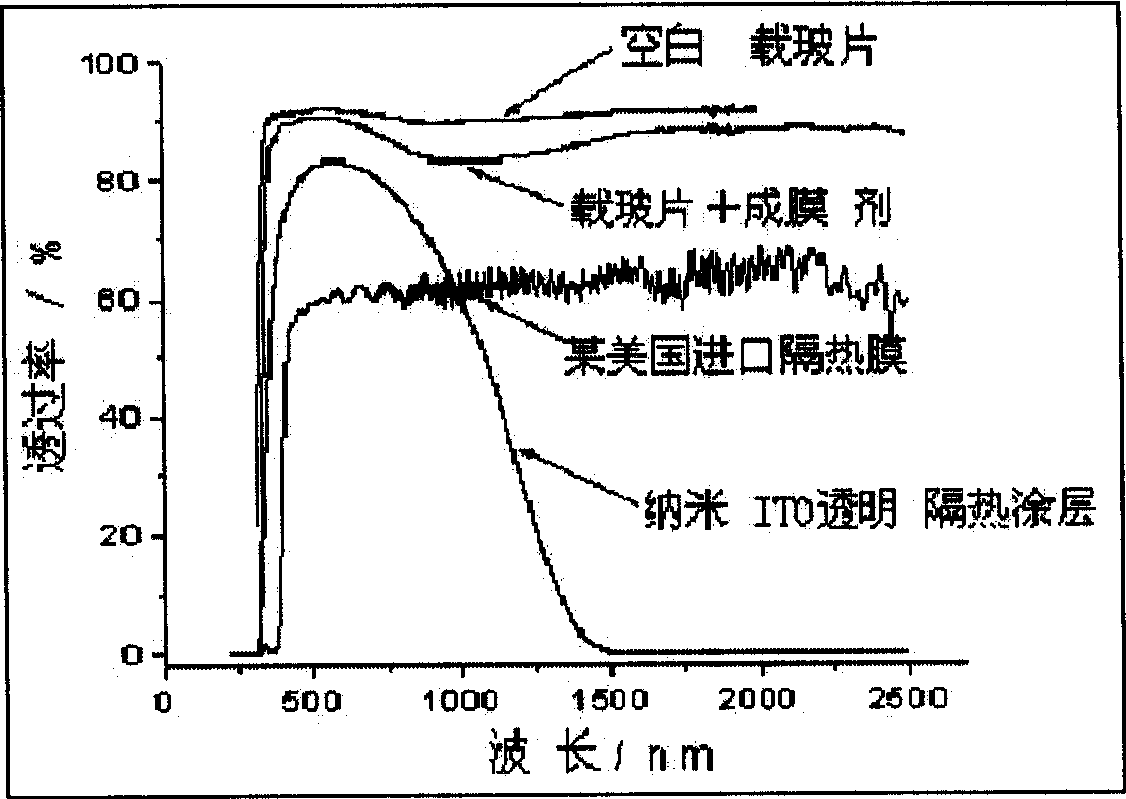

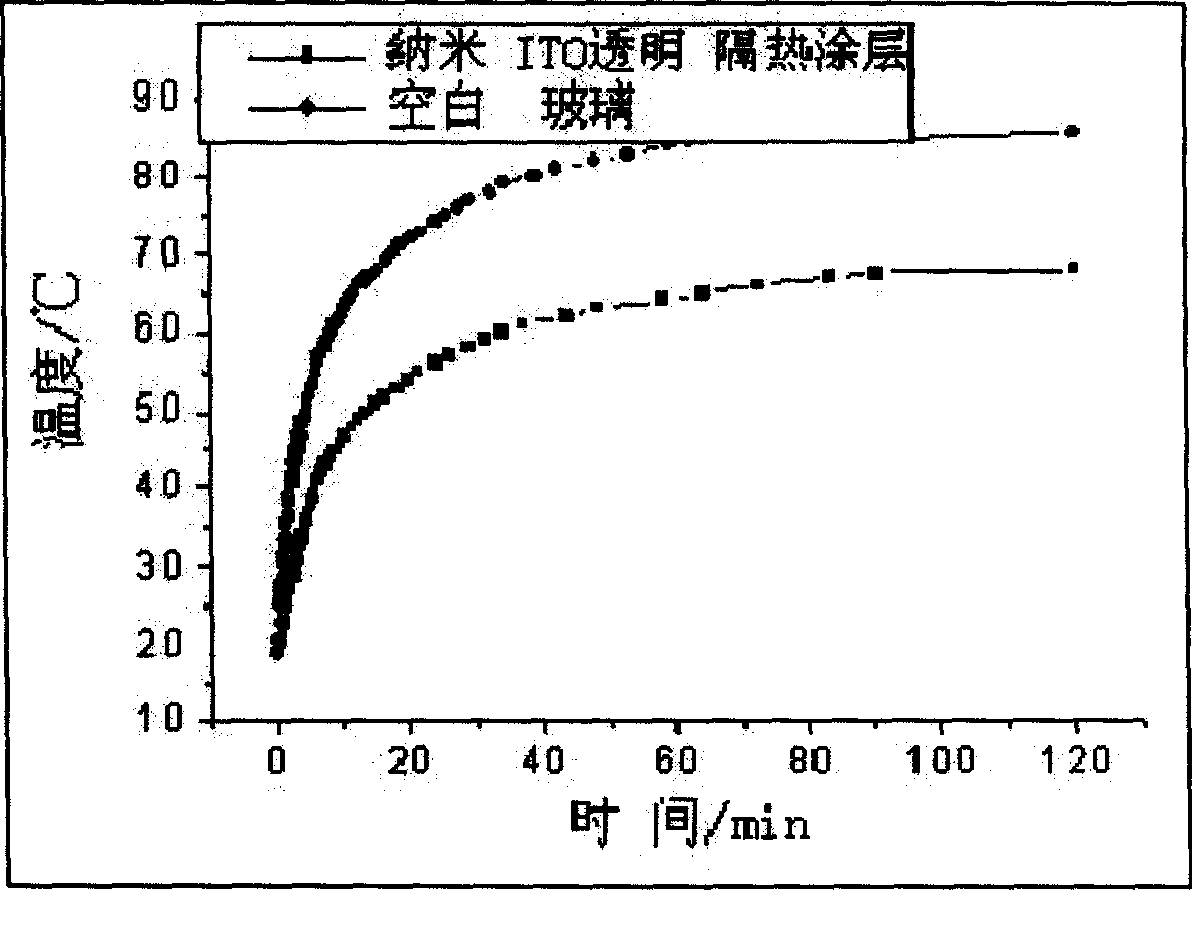

Insulating mold coating of transparent glass and manufacturing method thereof

InactiveCN101362630ATransparent goodGood heat insulationDIETHYLENE GLYCOL MONOETHYL ETHER ACETATEThermal insulation

The invention relates to a transparent glass thermal insulation coating and a manufacturing method thereof, the mixing ratio of the formula is as follows: 68 to 75 parts of modified acrylic resin; 8 to 10 parts of indium-tin oxide; 7 to 12 parts of isopropyl acetate; 5 parts of benzene-free diluent JW; 3 parts of diethylene glycol monoethyl ether acetate; and 2 parts of ultraviolet absorbent UV-9; the modified acrylic resin is firstly added in a dispersing barrel, the indium-tin oxide, the isopropyl acetate, the benzene-free diluent JW and the diethylene glycol monoethyl ether acetate are sequentially added under the stirring situation, then the high-speed stirring is carried out for 15 minutes, after that, the ultraviolet absorbent UV-9 is added therein, the stirring is further carried out for 20 minutes, and a finished product can be finally produced. The produce which is produced by adopting the method has the performances of high strength, high toughness, wear resistance, good stability and the like; the product further has the permanent anti-UV performance, when the product is taken as a finish coat paint, a coating layer is difficult to be aged and peeled off, the color of the coating can maintain the brightness for a long time, thereby having ultra-durability; the performances are good, the process conditions are simple and easy to operate, and the cost is lower.

Owner:刘昆虎

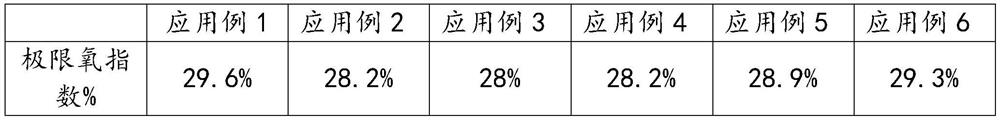

Flame-retardant rosin phenolic resin paint for copper sculpture

The invention relates to paint, and in particular relates to flame-retardant rosin phenolic resin paint for a copper sculpture. The paint is prepared from the following raw materials in parts by weight: 34-36 parts of rosin phenolic resin, 4-6 parts of turpentine, 2-3 parts of cobalt iso-octoate, 10-12 parts of pentaerythritol, 1-2 parts of hydroxyl nonyl copper benzene sulfonate, 2-3 parts of potassium fluozirconate, 10-20 parts of diethylene glycol monoethyl ether acetate, 1-2 parts of polytetrafluoroethylene, 3-4 parts of 2-butoxy-ethanol, 12-15 parts of aluminum hydroxide, 5-8 parts of nano calcium carbonate, 1-2 parts of accelerant TM TM, 1-2 parts of monobutyl tin oxide, 6-9 parts of diamino diphenyl sulfone, 5-6 parts of aids, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The paint has the advantages of light weight, high rigidity, high glossiness, bright color, safety, flame retardance, heat resistance, stable chemical performance, long service life and relatively simple production process and is widely applied for protecting copper sculpture artware in various environments.

Owner:TONGLING XINJIUDING COPPER CULTURE IND

UV heat insulation paint used for transparent packaging bag

The invention discloses an UV heat insulation paint used for transparent packaging bag, which belongs to the technical field of paint. The UV heat insulation paint used for transparent packaging bag comprises the following components by weight part: 60-80 part of epoxy acrylate, 5-10 parts of benzoin ethyl ether, 10-15 parts of powdered steatile, 0.3-1 part of levelling agent, 0.1-0.8 parts of antifoaming agent, 0.5-1.2 parts of titanium dioxide, 0.5-1 part of delustering agent, 1-3 parts of ethylhexyl acrylate, 5-10 parts of modified acrylic resin, 1-3 parts of indium tin oxide, 1-3 parts of isopropyl acetate, 1-3 parts of non-benzene diluents JW, and 1-3 parts of diethylene glycol monoethyl ether acetate. After using the paint coated on the external surface of the packaging bag, the packaging bag has the advantages of heat insulation, sterilization, food preservation, storage and shelf-life prolongation.

Owner:安徽浩峯塑业有限公司

Mining equipment wear-resistant finishing paint

InactiveCN108753120AImprove wear resistanceReduce the phenomenon of corrosionWax coatingsAnti-corrosive paintsWear resistantTurpentine

The invention discloses a mining equipment wear-resistant finishing paint. The mining equipment wear-resistant finishing paint comprises, by mass, 30 to 40 parts of epoxy acrylate, 15 to 25 parts of styrene acrylic emulsion, 2 to 5 parts of silica micropowder, 10 to 18 parts of palm wax, 10 to 20 parts of turpentine, 15 to 25 parts of butanol, 2 to 5 parts of aramid short fiber, 10 to 18 parts ofalumina, 5 to 10 parts of xylene, 3 to 6 parts of butyl ether, 5 to 10 parts of diethylene glycol monoethyl ether acetate, 20 to 24 parts of fluororesin, and 6 to 10 parts of butyl ester. In preparation process, styrene acrylic emulsion, silica micropowder, and palm wax are added, so that mining equipment wear resistance is improved greatly, corrosion of mining equipment in using process is reduced, and equipment service life is prolonged.

Owner:HUAINING JIANGZHEN DAIJIAAO COPPER MINE

Preparation process of flame-retardant polyester resin and application of flame-retardant polyester resin in flame-retardant coatings

ActiveCN112592468AImprove performanceHigh activityFireproof paintsPolyester coatingsDIETHYLENE GLYCOL MONOETHYL ETHER ACETATEPolymer science

The invention discloses a preparation process of flame-retardant polyester resin, which is characterized by comprising the following steps: adding a flame-retardant reinforcing agent, absolute ethyl alcohol and a sodium hydroxide solution with the mass concentration of 18% into a reaction kettle, stirring to dissolve, adding saturated polyester resin liquid, reacting for a period of time, adding asaturated solution of sodium carbonate, dropwise adding diaminosilane after stirring and reacting for 4 hours, continuously adding diethylene glycol monoethyl ether acetate in the reaction process, carrying out rotary evaporation to recover the solvent, and washing the product to be neutral to obtain the flame-retardant polyester resin. According to the flame-retardant polyester resin prepared bythe invention, the saturated polyester resin is subjected to cross-linking polymerization by virtue of a flame-retardant enhancer, and two amino groups in the diaminosilane added into the saturated polyester resin can be subjected to addition reaction with olefin groups, so that the polyester resinis cross-linked with flame-retardant enhancer and then cross-linked by virtue of the diaminosilane to form a reticular structure; therefore, the prepared resin has relatively strong performance.

Owner:宁波顺声通讯设备有限公司

High-temperature-resistant and ageing-resistant cable sheath material and preparing method thereof

InactiveCN105623007AExtended service lifeImprove high temperature resistanceHydrogenated Palm Kernel OilChlornitrofen

The invention discloses a high-temperature-resistant and aging-resistant cable sheath material. The high-temperature-resistant and aging-resistant cable sheath material is prepared from, by weight, 60-80 parts of nitrile butadiene rubber, 25-35 parts of methyl vinyl silicone rubber, 3-8 parts of zinc oxide, 2-7 parts of magnesium stearate, 12-18 parts of diethylene glycol monoethyl ether acetate, 10-16 parts of 2,2,2-trichloroacetamide benzyl ester, 11-18 parts of ethopabate, 4-10 parts of acetazolamide, 3-7 parts of magnalium zirconium oxide, 4-7 parts of zirconocene dichloride, 1-4 parts of hydrogen-chlorine ferrocene, 10-15 parts of bifenox and 12-18 parts of hydrogenated palm kernel oil. According to the high-temperature-resistant and aging-resistant cable sheath material, at the high temperature of 150 DEG C, changes of all performances are small, aging resistance is high, and the performance is stable.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Low-temperature setting environment-friendly conductive silver paste and preparing method thereof

InactiveCN104143382AGood weather resistanceImprove wear resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureDIETHYLENE GLYCOL MONOETHYL ETHER ACETATESilver paste

The invention discloses a low-temperature setting environment-friendly conductive silver paste which is characterized by comprising, by weight, 40-45 parts of silver powder, 2-3 parts of quartz, 3-5 parts of mica, 1.3-2.4 parts of p-toluenesulfonic acid, 0.4-0.9 part of copper naphthenate, 4-6 parts of diethylene glycol monoethyl ether acetate, 2-4 parts of linoleic acid, 2.1-3.4 parts of benzalkonii bromidum, 0.5-1.2 parts of palmitoleic acid, 30-35 parts of auxiliaries, and a proper amount of water. According to the low-temperature setting environment-friendly conductive silver paste, quartz is added to serve as a modification material, so that the weather resistance and abrasion resistance of the conductive silver paste are improved. The conductive silver paste obtained through technical formula improvement has the advantages of being low in setting temperature, stable in quality, light in toxicity, low in cost, and broad in application prospect.

Owner:滁州恒恩光电科技有限公司

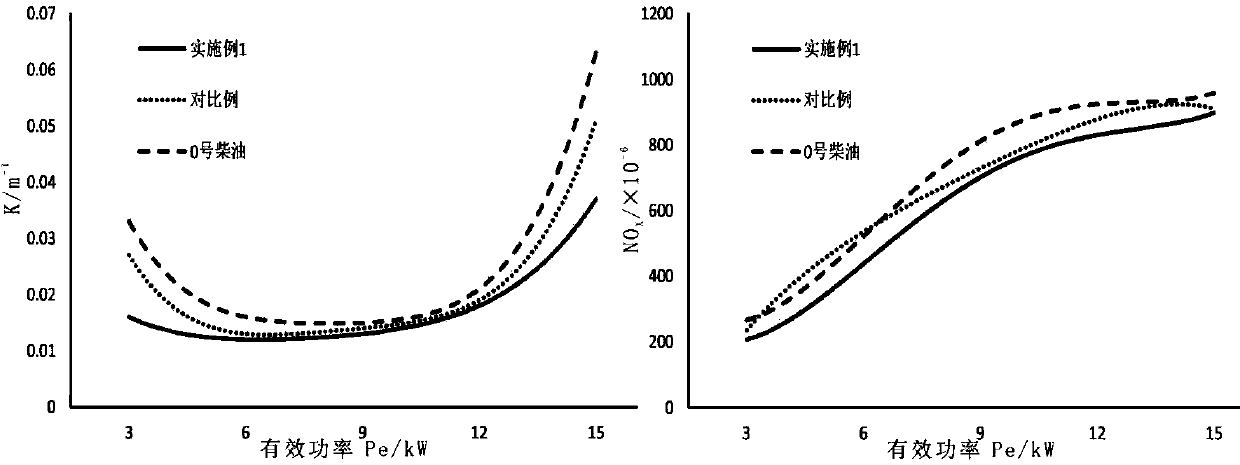

Composite biodiesel and preparation method thereof

InactiveCN105567347AImprove stabilityIncrease oxygen contentBiofuelsLiquid carbonaceous fuelsIsobutanolPolyoxyethylene castor oil

The invention discloses composite biodiesel prepared from the following components in parts by weight: 220 parts of biodiesel, 780 parts of petrochemical diesel, 52 parts of isobutanol, 16 parts of 2-Ethyl Hexyl Di Glycol, 2.2 parts of iso-octyl nitrate, 16 parts of Isomeric alcohol ethoxylates, 27 parts of polyoxyethylene castor oil, 22 parts of Polyethylene Glycol Sorbitol Tetraoleate, 11 parts of Diethylene glycol monoethyl ether acetate, 13 parts of didecyldimethylammonium chloride and 200 parts of water. The composite biodiesel is excellent in stability, high in stability and not easy to layer, and can meet fuel material storage requirements. The composite biodiesel has higher oxygen content, and can reduce emissions of soot in the combustion process, overall NOX emission is low, and the problem of environmental pollution generated in diesel engine application can be effectively solved.

Owner:阳江欧粤新能源科技有限公司

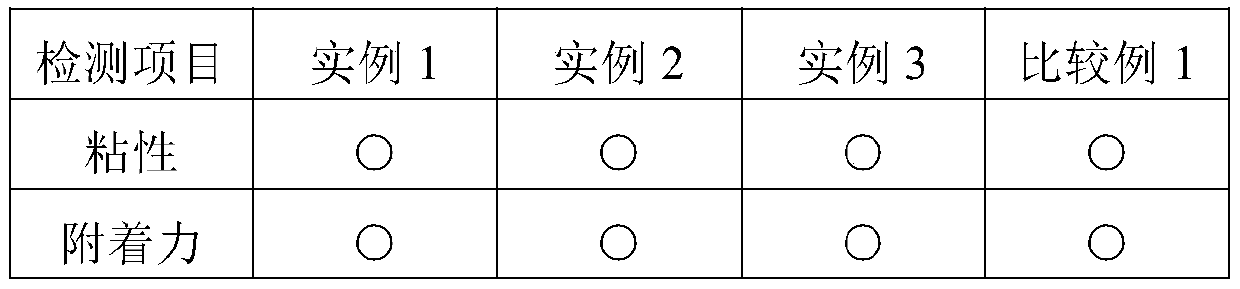

Photosensitive resin and application of photosensitive resin to preparation of liquid photosensitive solder resist ink

ActiveCN110673442AEmission reductionMeets requirementsInksPhotosensitive materials for photomechanical apparatusPolymer scienceAcrylic resin

The invention discloses photosensitive resin and application of the photosensitive resin to the preparation of liquid photosensitive solder resist ink. The photosensitive resin is prepared from the following raw materials in parts by weight: 200 to 300 parts of bisphenol A type epoxy acrylic resin; 180 to 190 parts of diethylene glycol monoethyl ether acetate; 45 to 90 parts of acrylic acid; 2 to8 parts of N, N-dimethyl benzylamine; 2 to 8 parts of hydroquinone; and 45 to 90 parts of tetrahydrophthalic anhydride. Matrix resin synthesized from the photosensitive resin has better toughness, more excellent hydrophilicity and more excellent dehydration performance in the production process compared with matrix resin in the prior art. When the photosensitive resin is added into the formula ofthe liquid photosensitive solder resist ink, the discharge amount of VOCs (volatile organic compounds) of the ink is greatly reduced.

Owner:新东方油墨有限公司

Method of forming photoresist pattern

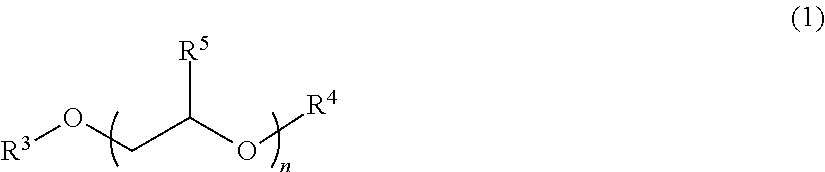

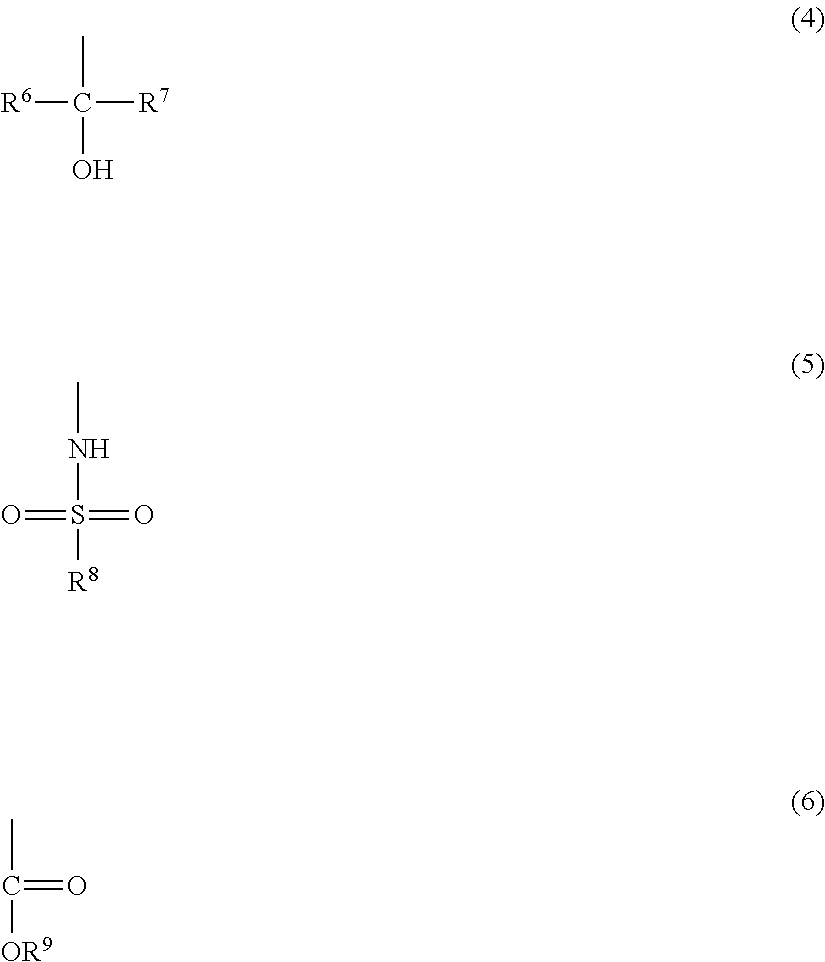

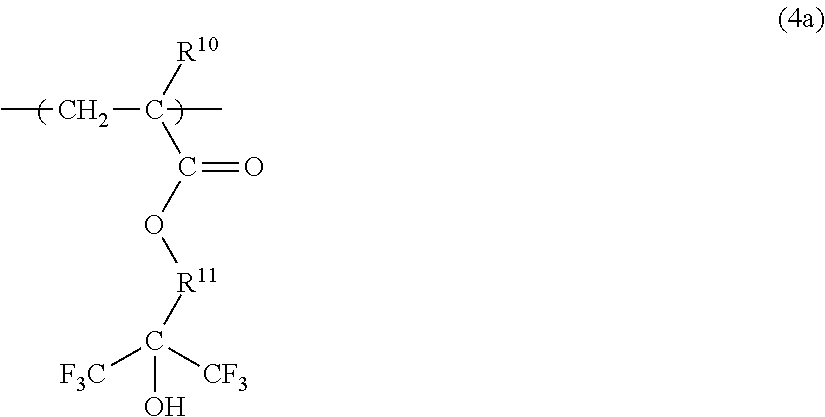

InactiveUS20140147794A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDiethylene glycol diethyl etherDIETHYLENE GLYCOL MONOETHYL ETHER ACETATE

Owner:JSR CORPORATIOON

Semi-rigid polyvinyl chloride portrait calendered film

The invention discloses a semi-rigid polyvinyl chloride portrait calendered film. The semi-rigid polyvinyl chloride portrait calendered film comprises the following components in parts by weight: 60-70 parts of polyvinyl chloride resin, 15-20 parts of an acrylonitrile-butadiene-styrol copolymer, 14-20 parts of corundum fine powder, 9-13 parts of melamine cyanurate, 23-29 parts of glass fiber, 2-3 parts of gelatin, 25-35 parts of octyltin mercaptide, 18-28 parts of silicon carbide powder, 14-20 parts of magnesium hypophosphite, 3-6 parts of di-sec-butyl-p-phenylene, 3-7 parts of meerschaum, 9-17 parts of sodium salicylate, 3-8 parts of titanium dioxide, 10-20 parts of benzoin ethyl ether, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie bone, 13-15 parts of acetyl tributyl citrate, 2-3 parts of diethylene glycol monoethyl ether acetate, and 3-4 parts of glycerin. The calendered film has the advantages of high strength, good temperature toleration, good covering rate, and good ink absorbency, can replace the traditional portrait paper, and can make up the defect of nano calcium by adding corundum fine powder and silicon carbide powder.

Owner:桐城市弘业塑胶有限公司

Wear-resistant finishing paint for mining equipment

InactiveCN107828303AImprove wear resistanceReduce the phenomenon of corrosionWax coatingsAnti-corrosive paintsWaxDIETHYLENE GLYCOL MONOETHYL ETHER ACETATE

The invention discloses wear-resistant finishing paint for mining equipment. The finishing paint is characterized by comprising the following components in parts by mass: 70-80 parts of a hydroxyl acrylic emulsion, 8-25 parts of a pigment, 3-6 parts of a metal drier, 4-10 parts of a modified filler, 15-25 parts of a styrene-acrylic emulsion, 2-5 parts of silicon micro powder, 10-18 parts of palm wax, 5-10 parts of xylene, 3-6 parts of butyl ether, 5-10 parts of diethylene glycol monoethyl ether acetate, 20-24 parts of fluorine resin and 6-10 parts of butyl ester. In the finishing paint for themining equipment provided by the invention, the styrene-acrylic emulsion, the silicon micro powder and the palm wax are added, so that the wear resistance of the mining equipment is greatly improved,the phenomenon that the mining equipment is corroded in a using process is reduced, and the service life of the equipment is prolonged.

Owner:JIANGSU MINJIANG MINING CO LTD

Inner wall toughening agent for fiber-toughened and heat-resisting optical fiber outer sleeve

The invention provides an inner wall toughening agent for a fiber-toughened and heat-resisting optical fiber outer sleeve. The toughening agent is prepared from components as follows: 40-60 parts of glass beads, 50-70 parts of acid-resisting powder particles, 20-25 parts of a 50% sodium hydroxide aqueous solution, 0.5-2 parts of a dispersing agent, 2-18 parts of an emulsifier, 0.5-1 part of a preservative, 0.5-5 parts of a surfactant, 2.5-5 parts of ammonium hydroxide, 2-4 parts of a binder, 50-60 parts of water, 0.9-6 parts of a thickening agent, 1-12 parts of a film-forming agent, 15-20 parts of methyl methacrylate, 10-15 parts of melamine formaldehyde resin, 3-6 parts of polypropylene resin, 20-30 parts of diethylene glycol monoethyl ether acetate and 3-8 parts of nonylphenol polyoxyethylene ether. According to the toughening agent, thermal decomposition temperature and char forming amount of a material are increased, heat stability of the material is improved, continuous degradation of the material is ended, a heat release value of the material is reduced, surface strength of a finished product can be effectively improved, and weather fastness is improved.

Owner:ANHUI COMM IND SERVICE CO LTD

High-toughness waterproof material formula

InactiveCN108587371AHigh bonding strengthGood waterproof and anti-penetration performanceCoatingsXylylenePolyethylene glycol

The invention discloses a high-toughness waterproof material formula, and relates to the field of material chemistry. The high-toughness waterproof material formula is prepared from the following rawmaterials including polyacrylate emulsion, amino modified hydroxyl silicon oil emulsion, turpentine-based waterborne polyester resin, gelling materials, polyethylene, polytetrafluoroethylene, polytrifluorochloroethylene, poly-p-xylylene, triethanolamine, diethylene glycol monoethyl ether acetate, polyethylene glycol diamine, gamma-decalactone, trans-2-decenal, flowing modifying agents, hydroxypropyl cellulose, styrene-acrylic emulsion, antibacterial agents, surfactants, ultraviolet light absorbers, anti-fouling agents and anti-aging agents. The high-toughness waterproof material formula has the advantages that the cost is low; the anti-corrosion and antibacterial effects are good; the industrialization is easy; in addition, the excellent hardness is realized; the waterproof performance isgood; the falling cannot easily occur; the environment pollution can be effectively reduced.

Owner:侯娟

Novel plastic formula for hard PVC board

InactiveCN106280407AIncrease temperatureGood for high speed machiningTributyl citrateMaterials science

The invention discloses a novel plastic formula for a hard PVC board. The hard PVC board is prepared from, by weight, 60-70 parts of nylon, 15-20 parts of PVC, 14-20 parts of fine corundum powder, 9-13 parts of melamine cyanurate, 23-29 parts of glass fibers, 25-35 parts of octyltin mercaptide, 18-28 parts of silicon carbide powder, 14-20 parts of sodium carboxymethylcellulose, 3-6 parts of potassium nitrate, 3-7 parts of sepiolite, 9-17 parts of sodium salicylate, 3-8 parts of titanium dioxide, 10-20 parts of asbestos powder, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 13-15 parts of acetyl tributyl citrate, 2-3 parts of diethylene glycol monoethyl ether acetate, 3-4 parts of sodium oxide, 0.2-0.4 part of nano-aluminum oxide, 0.2-0.4 part of palladium nitrate, 0.2-0.4 part of nano-zirconia, 0.2-0.4 part of nano-cerium oxide, 0.2-0.4 part of nano-neodymium oxide and 0.2-0.4 part of nano-yttria. According to the formula, the application temperature of the hard PVC board is raised, machining performance is optimized, high-speed machining of the PVC board is promoted, and machining efficiency of products is improved.

Owner:桐城市弘业塑胶有限公司

Photosensitive resin composition, dry film, and method for manufacturing printed circuit board

PendingCN110320749AUniform coatingInhibition of contractionPhotomechanical apparatusNon-metallic protective coating applicationPrinted circuit boardDIETHYLENE GLYCOL MONOETHYL ETHER ACETATE

Provided is a photosensitive resin composition, a dry film, and a method for manufacturing a printed circuit board. The photosensitive resin composition can suppress shrinkage or sagging after coatingor drying, form a uniform dry coating film after drying and can suppress a short circuit. The photosensitive resin composition of the present invention includes a carboxyl group-containing resin, a thermosetting resin, a photosensitive monomer, and an organic solvent. The organic solvent includes diethylene glycol monoethyl ether acetate, dipropylene glycol monomethyl ether, and propylene glycolmonomethyl ether acetate.

Owner:TAIYO INK MFG

Coating capable of improving heat resistance and corrosion resistance of automobile exhaust pipes and application method of such coating

InactiveCN106811111AEffective anti-rustImprove adhesionFireproof paintsAntifouling/underwater paintsThioureaExhaust pipe

The invention belongs to the technical field of metal heat-resistant coatings and particularly relates to a coating capable of improving heat resistance and corrosion resistance of automobile exhaust pipes and an application method of such coating. The coating is prepared from bismaleimide resin, acetanilide, sodium metaaluminate, hydroxycamptothecine, thiourea, C60-thiophene pyrrolidine, ultrafine copper powder, methyl cyclohexane, diethylene glycol monoethyl ether acetate, benzyl dimethylamine and water. Compared with the prior art, the coating has the advantages that a compact thin film is formed on the surface of a matrix of the bismaleimide resin to make the matrix rustproof effectively, and adhesive force between a coating film and the matrix is improved through the methyl cyclohexane and the diethylene glycol monoethyl ether acetate, so that durability and resistance to water and high temperatures are enhanced; the automobile exhaust pipes coated with the coating are highly resistant to fouling and corrosion at high temperatures and highly resistant to rusting, and accordingly the coating guarantees appearance persistence and durability of the automobile exhaust pipes and is suitable for popularization and use.

Owner:安徽雷萨重工机械有限公司

Environment-friendly low-temperature type anti-corrosive paint

ActiveCN105062250AImprove waterproof performanceScrub resistantAnti-corrosive paintsSlagCis-Butenedioic Acid

The present invention discloses environment-friendly low-temperature type anti-corrosive paint which comprises the following components in parts by weight: 12-25 parts of main raw materials, 5-20 parts of a plasticizer, 10-25 parts of pigments, 15-40 parts of an auxiliary agent, and 5-25 parts of a diluent; wherein the main raw materials are polyethylene resin and vinylidene chloride in a mass ratio of 1:1.5; the plasticizer is one of dioctyl adipate, dioctyl phthalate, dibutyl maleate, butanediol dimethacrylate, and dibutyl fumarate; the pigment is one of barite powder, mica powder, bentonite, light calcium powder, heavy calcium powder, and carbide slag dry-powder; the auxiliary agent is one of trimethyl hydroxypentyl isobutyrate, dodecanol ester, diethylene glycol monoethyl ether acetate and ethylene glycol monoethyl ether acetate ; and the diluent is one of a coal-tar solvent 200, ethyl acetate, butyl acetate, amyl acetate. According to the present invention, the paint is good in waterproof performance, high in strength, strong in low-temperature adapting ability, and is energy-saving and environmentally friendly.

Owner:鞍钢钢结构(营口)有限公司

An environmentally friendly low-temperature anticorrosive paint

ActiveCN105062250BImprove waterproof performanceScrub resistantAnti-corrosive paintsSlagCis-Butenedioic Acid

The present invention discloses environment-friendly low-temperature type anti-corrosive paint which comprises the following components in parts by weight: 12-25 parts of main raw materials, 5-20 parts of a plasticizer, 10-25 parts of pigments, 15-40 parts of an auxiliary agent, and 5-25 parts of a diluent; wherein the main raw materials are polyethylene resin and vinylidene chloride in a mass ratio of 1:1.5; the plasticizer is one of dioctyl adipate, dioctyl phthalate, dibutyl maleate, butanediol dimethacrylate, and dibutyl fumarate; the pigment is one of barite powder, mica powder, bentonite, light calcium powder, heavy calcium powder, and carbide slag dry-powder; the auxiliary agent is one of trimethyl hydroxypentyl isobutyrate, dodecanol ester, diethylene glycol monoethyl ether acetate and ethylene glycol monoethyl ether acetate ; and the diluent is one of a coal-tar solvent 200, ethyl acetate, butyl acetate, amyl acetate. According to the present invention, the paint is good in waterproof performance, high in strength, strong in low-temperature adapting ability, and is energy-saving and environmentally friendly.

Owner:鞍钢钢结构(营口)有限公司

Environment-friendly waterproof material

The invention discloses an environment-friendly waterproof material, relating to the building field. The environment-friendly waterproof material is prepared from the following raw materials in partsby weight: polypropylene resin, aldehyde ketone resin, bentonite, polyurethane, polycarbonate diol, dipropylene glycol dibenzoate, triphenyl phosphate, trioctyl trimellitate, diatomite, triethanolamine, diethylene glycol monoethyl ether acetate, polyethylene glycol diamine, gamma-decalactone, trans-2-decenal, 3-hydroxy-2-methylpropene, tiglic acid, an inorganic antibacterial agent, an ultravioletabsorbent, a penetrant, a sun-blocking agent, a flame retardant and a solvent. The environment-friendly waterproof material is relatively strong in pressure resistance, relatively long in service life, good in high-temperature resistance and strong in crack resistance and adhesive force and has certain ductility, and a waterproof layer can be formed on the surface of an object, so that the oxidation of the object can be effectively avoided.

Owner:侯娟

Colorful oil-in-oil-based alkyd resin coating

InactiveCN104194597AImprove water resistanceImprove the decorative effectPolyester coatingsMulticolor effect coatingsAluminum silicateResin coating

The invention relates to colorful oil-in-oil-based alkyd resin coating which comprises the following raw materials in parts by weight: 100 parts of rosin modified alkyd resin, 35-45 parts of triphenyl phosphate, 20-40 parts of diethylene glycol monoethyl ether acetate, 10-20 parts of hydroquinone monomethyl ether, 15-35 parts of barium chromate, 1-10 parts of dioxin, 80-90 parts of deionized water, 25-35 parts of dimethylethanolamine, 10-20 parts of pigments, 30-40 parts of triethylamine, 20-30 parts of dipentene, 10-30 parts of tert-butyl peroxyoctoate, 6-8 parts of a plasticizer, 25-45 parts of methyl methacrylate, 30-40 parts of aluminum silicate and 15-25 parts of maleic anhydride. The colorful oil-in-oil-based alkyd resin coating has the benefits that the number of scrubbing resistance to the coating is 2000-3000 times; the water resistance is good, and no foam and no powder falling-off occur after the colorful oil-in-oil-based alkyd resin coating is socked in water for 60-80 days; the surface drying time is 1-2 hours, the hard drying time is 8-10 hours, and the time of resistance to alkaline saturated calcium hydroxide solution is 30-40 days; the coating has special patterns and good defective effect and can be widely produced and substitute the existing materials.

Owner:珠海撒比斯化学有限公司

Conductive silver adhesive and preparation method and application thereof

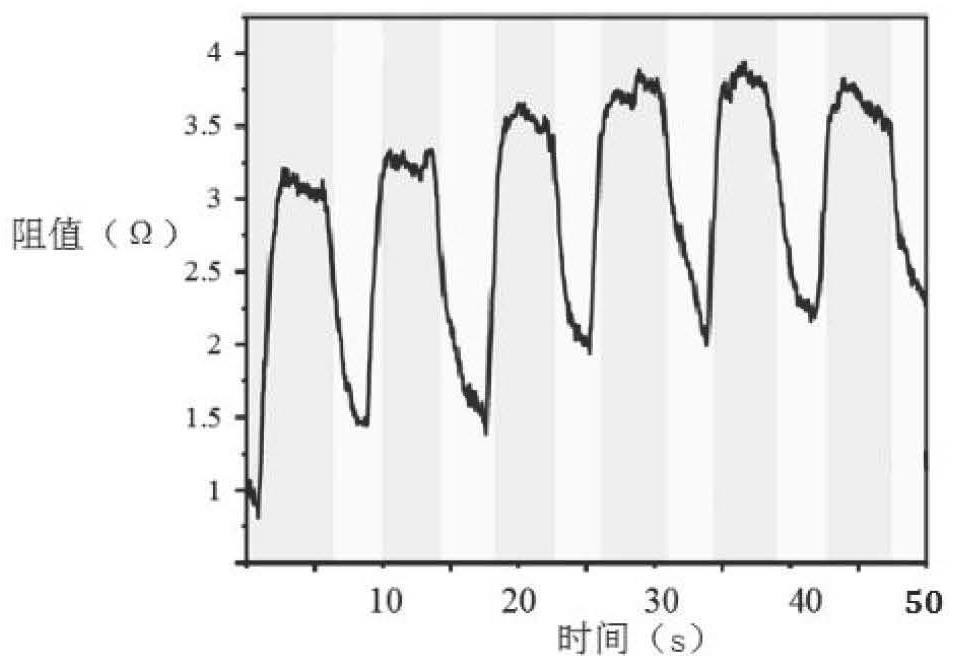

InactiveCN114181650AImprove electrical stabilityGood compatibilityNon-macromolecular adhesive additivesForce measurementEpoxyDIETHYLENE GLYCOL MONOETHYL ETHER ACETATE

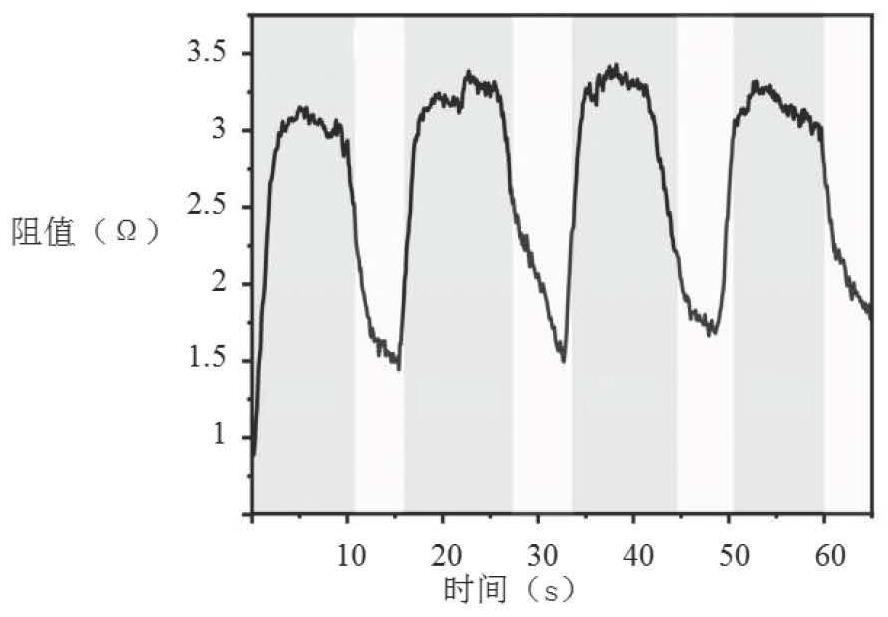

The invention provides a conductive silver adhesive. The conductive silver adhesive is prepared from the following raw materials in parts by mass: 40-90 parts of polyurethane modified epoxy resin, 10-30 parts of elastic polyurethane, 5-20 parts of diethylene glycol monoethyl ether acetate, 5-20 parts of diethylene glycol and 40-90 parts of conductive filler, the conductive filler is at least one of flaky silver powder, spherical silver powder, nano silver wire, linear graphite powder and spherical graphite powder. According to the conductive silver adhesive provided by the invention, the polyurethane modified epoxy resin is used as a base material, the elastic polyurethane is used as a flexible material, and the diethylene glycol and the diethylene glycol monoethyl ether acetate are used as auxiliaries, so that the compatibility of a system is improved, and the conductive silver adhesive still has excellent conductive stability after being stretched in cooperation with the conductive filler. The result of the embodiment shows that the sheet resistance of the conductive silver adhesive before stretching is 0.56-1029 omega, and the sheet resistance of the conductive silver adhesive after 5% stretching is 1.92-1498 omega.

Owner:JIAXING UNIV

Low-temperature cured conductive paste with ultra-low silver content and preparation method thereof

InactiveCN101950595BLow costLow priceNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingSuspending Agents

The invention provides a low-temperature cured conductive paste with ultra-low silver content, which is prepared by the following components in percentage by weight: 45-50% of conductive powder, 40-45% of solvent, 10-15% of macromolecule resin, and 0-5% of additive, wherein the conductive powder is a mixture of 35-40% of silver flake powder, 3-5% of conductive ferrophosphorus alloyed powder and 5-7% of conductive nickel powder accounting for the conductive paste in percentage by weight; the solvent is one of dibasic ester (DBE), diethylene glycol monoethyl ether acetate or 2-Butoxyethyl acetate; the macromolecule resin is hydroxyl-modified vinyl resin or polyester resin; and the additive comprises one or more of coupling agent, suspending agent, thickening agent and flatting agent. The silver content of the conductive paste of the invention is below 40%, and demands of customers on resistance and other aspects are met while reducing cost.

Owner:IRICO

A kind of oil-in-oil type alkyd resin colorful paint

InactiveCN104194597BImprove water resistanceImprove the decorative effectPolyester coatingsMulticolor effect coatingsAluminum silicateResin coating

Owner:珠海撒比斯化学有限公司

Buffing and gum-removing agent

InactiveCN109810808ASimple preparation processStable in natureOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsDiacetone alcoholPhenyl Ethers

The invention provides a buffing and gum-removing agent. The buffing and gum-removing agent is prepared from the following components in percent by mass: 15-50% of gum-removing solvent, 5-40% of auxiliary solvent and 20-50% of solubilizing agent, wherein the gum-removing solvent comprises one or several of dipropylene glycol dimethyl ether, dipropylene glycol monomethyl ether, diethylene glycol dimethyl ether, diethylene glycol monomethyl ether and diacetone alcohol; and the auxiliary solvent comprises one or several of propylene glycol phenyl ether acetate, aceticacidphenoxyethylester, diethylene glycol monoethyl ether acetate and propylene glycol methyl ether acetate. The buffing and gum-removing agent provided by the invention can act with residual buffing gum quickly, so that the residual buffing gum can be quickly separated from a disc surface of a machine platform. The buffing and gum-removing agent is simple in preparation process, stable in property and excellent in effect. Allthe residual buffing gum can be removed by only 10-40 s. The flashing point of the buffing and gum-removing agent is 55 DEG C or above, so that the buffing and gum-removing agent is safe and is not prone to fire blast. The components used by the buffing and gum-removing agent do not contain benzene, chloride, heavy metal and the like, so that the buffing and gum-removing agent is relatively low in odor and is green and environmentally friendly.

Owner:LENS TECH CHANGSHA

High-temperature-resistant and corrosion-resistant protective film for blister box

InactiveCN114316690AGood flexibilityImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerDIETHYLENE GLYCOL MONOETHYL ETHER ACETATE

The invention provides a high-temperature-resistant and corrosion-resistant protective film for a blister box, which is prepared from the following components in parts by weight: 45 to 60 parts of polystyrene, 15 to 20 parts of polyurethane resin, 2 to 6 parts of POE (Polyolefin Elastomer) resin, 3 to 7 parts of diethylene glycol monoethyl ether acetate, 2 to 6 parts of methacrylic acid, 0.05 to 0.1 part of Bi2MoO6, 0.5 to 1 part of Ti3AlC2 and 0.2 to 0.6 part of magnesium fluoride. According to the high-temperature-resistant and corrosion-resistant protective film for the blister box, the advantages of the polyurethane resin and the POE resin are utilized, the polyurethane resin and the POE resin are combined to complement each other, and the mechanical strength of the protective film for the blister box is improved; and by introducing nanoscale Ti3AlC2 and magnesium fluoride with the functions of high temperature resistance, corrosion resistance and aging resistance, the high temperature resistance, corrosion resistance and aging resistance of the protective film are improved, and the lampshade can have the long service life.

Owner:常州凌迪电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com