Photosensitive resin and application of photosensitive resin to preparation of liquid photosensitive solder resist ink

A technology of photosensitive solder resist ink and photosensitive resin, which is applied in the direction of photosensitive materials, inks, and applications for photomechanical equipment, which can solve problems such as pollution, increased PCB production costs, and large emissions of organic volatiles, and achieve reduction Effects of production cost, efficiency improvement and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

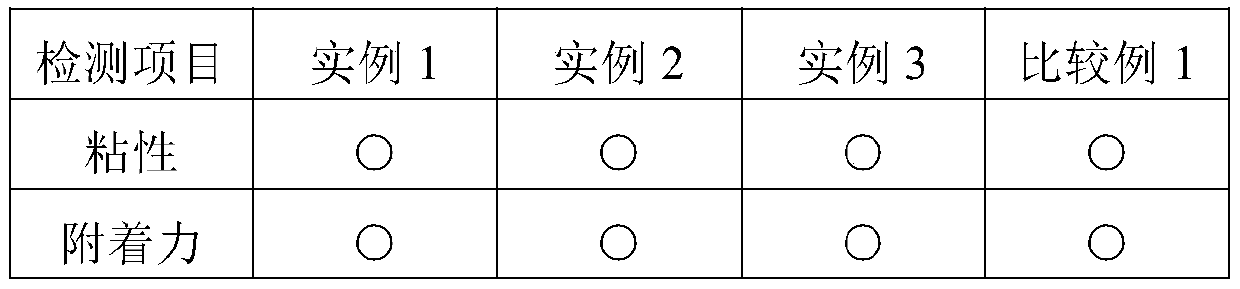

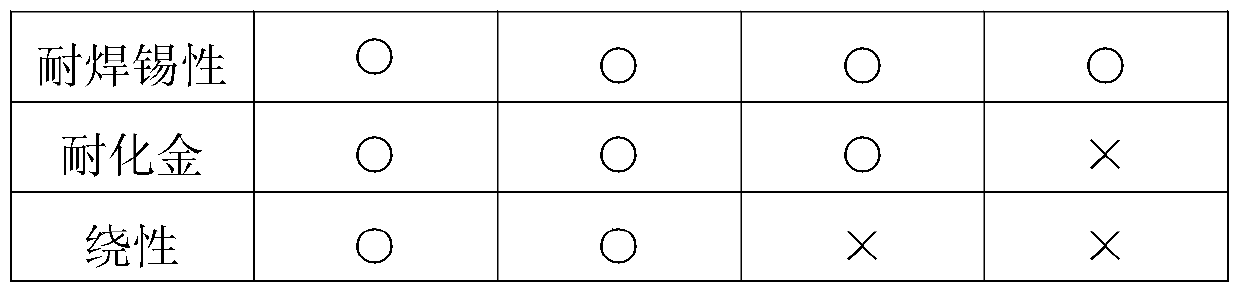

Examples

Embodiment 1

[0018] The preparation method of the photosensitive resin described in this embodiment is: add 235 grams of bisphenol A type epoxy acrylic resin modified by special epoxy resin and 180 grams of diethylene glycol ethyl ether acetate in a three-necked flask, and add 72 grams of acrylic acid, 4 grams of N, N-dimethylbenzylamine, 4 grams of hydroquinone, heated to 100 ° C for 10 hours, then added 90 grams of tetrahydrophthalic anhydride and heated to 110 ° C for 5 hours to obtain A photosensitive resin with an acid value of 63.5 mgKOH / g and a solid content of 68%.

Embodiment 2

[0020] The preparation method of the photosensitive resin described in this embodiment is: add 235 grams of bisphenol A type epoxy acrylic resin modified by special epoxy resin and 185 grams of diethylene glycol ethyl ether acetate in a three-necked flask, and add 72 grams of acrylic acid, 4 grams of N, N-dimethylbenzylamine, 4 grams of hydroquinone, heated to 100 ° C for 10 hours, then added 65 grams of tetrahydrophthalic anhydride and heated to 110 ° C for 5 hours to obtain A photosensitive resin with an acid value of 59 mgKOH / g and a solid content of 68%.

Embodiment 3

[0022] The preparation method of the photosensitive resin described in this embodiment is: add 235 grams of bisphenol A type epoxy acrylic resin modified by special epoxy resin and 190 grams of diethylene glycol ethyl ether acetate into a three-necked flask, and add 72 grams of acrylic acid, 4 grams of N, N-dimethylbenzylamine, 4 grams of hydroquinone, heated to 100 ° C for 10 hours, then added 45 grams of tetrahydrophthalic anhydride and heated to 110 ° C for 5 hours to obtain A photosensitive resin with an acid value of 56.4 mgKOH / g and a solid content of 68%.

[0023] comparison example

[0024] The preparation method of the photosensitive resin described in this comparative example is: add 220 g of silicone-modified novolac epoxy resin and 231.5 g of diethylene glycol monoethyl ether acetate into a three-necked flask and heat it to 70° C. to dissolve, and then add methyl 88g of acrylic acid, 1.5g of N,N-dimethylbenzylamine, 100g of toluene, 1g of concentrated sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com