Coating capable of improving heat resistance and corrosion resistance of automobile exhaust pipes and application method of such coating

A technology for corrosion resistance and automobile exhaust, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve problems such as rust, affecting functions, and affecting car appearance, so as to improve durability and ensure long-lasting Durability and durability, anti-rust effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

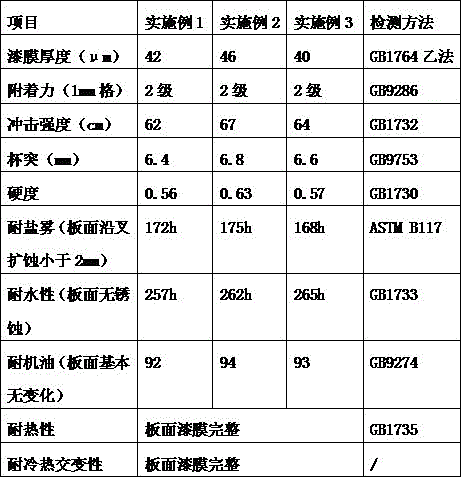

Examples

Embodiment 1

[0012] A coating for improving the heat and corrosion resistance of automobile exhaust pipes, which is made of the following raw materials in parts by weight: 18 parts of bismaleimide resin, 8 parts of acetanilide, 2 parts of sodium metaaluminate, and hydroxycamptothecin 0.8 parts, 3 parts of thiourea, 7 parts of C60-thiophene pyrrolidine, 8 parts of ultra-fine copper powder, 2 parts of methylcyclohexane, 7 parts of diethylene glycol monoethyl ether acetate, 4 parts of benzyl dimethylamine, 22 parts of water;

[0013] The preparation method comprises the following steps: after mixing bismaleimide resin and acetanilide, the temperature is raised to 95-105° C., and after stirring for 1.5-2 hours, ultra-fine copper powder and sodium metaaluminate are added, and then heat-preserved and stirred for 5 After -10 minutes, cool down to 55-60°C, add the remaining raw materials, stir evenly, cool to room temperature naturally, and use after standing for 3.5-4 hours.

[0014] Wherein, th...

Embodiment 2

[0018] A coating for improving the heat and corrosion resistance of automobile exhaust pipes, which is made of the following raw materials in parts by weight: 24 parts of bismaleimide resin, 6 parts of acetanilide, 3 parts of sodium metaaluminate, and hydroxycamptothecin 0.6 parts, 4 parts of thiourea, 6 parts of C60-thiophene pyrrolidine, 9 parts of ultrafine copper powder, 2 parts of methylcyclohexane, 5 parts of diethylene glycol monoethyl ether acetate, 3 parts of benzyl dimethylamine, 24 parts of water;

[0019] The preparation method comprises the following steps: after mixing bismaleimide resin and acetanilide, the temperature is raised to 100° C., and after stirring for 2 hours, superfine copper powder and sodium metaaluminate are added, and then the temperature is lowered after stirring for 10 minutes. to 60°C, add the remaining raw materials, stir evenly, cool to room temperature naturally, and use after standing for 4 hours.

[0020] Its method of use is the same a...

Embodiment 3

[0022] A coating for improving the heat and corrosion resistance of automobile exhaust pipes, made of the following raw materials in parts by weight: 26 parts of bismaleimide resin, 4 parts of acetanilide, 2 parts of sodium metaaluminate, and hydroxycamptothecin 0.8 parts, 5 parts of thiourea, 4 parts of C60-thiophene pyrrolidine, 10 parts of ultra-fine copper powder, 2 parts of methylcyclohexane, 3 parts of diethylene glycol monoethyl ether acetate, 4 parts of benzyl dimethylamine, 26 parts of water;

[0023] The preparation method comprises the following steps: after mixing bismaleimide resin and acetanilide, the temperature is raised to 105° C., and after stirring for 2 hours, superfine copper powder and sodium metaaluminate are added, and then the temperature is lowered after stirring for 10 minutes. To 55-60 ℃, add the remaining raw materials, stir evenly, cool down to room temperature naturally, and use after standing for 3.5 hours.

[0024] Its method of use is the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com