Insulating mold coating of transparent glass and manufacturing method thereof

A technology of transparent glass and heat-insulating paint, applied in the field of paint manufacturing, can solve the problems of easy brittleness of the paint film, poor emulsion hardness, poor hardness, etc., and achieve the effects of good adhesion, excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

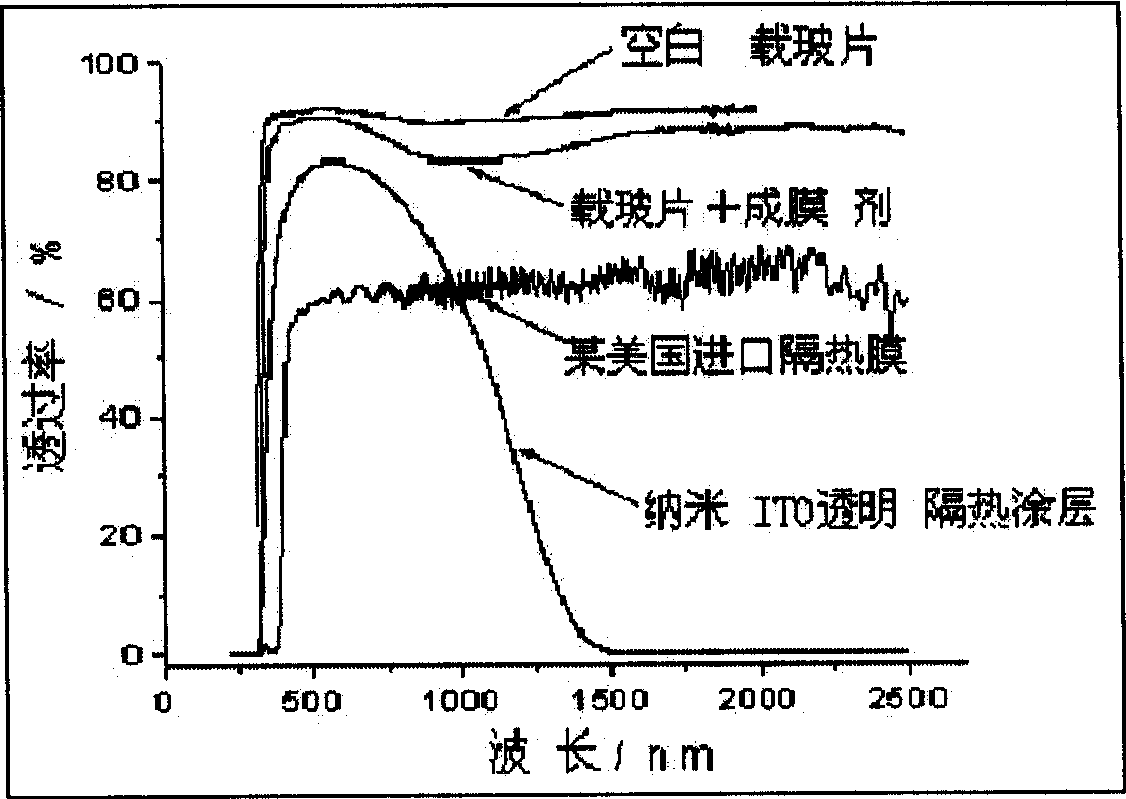

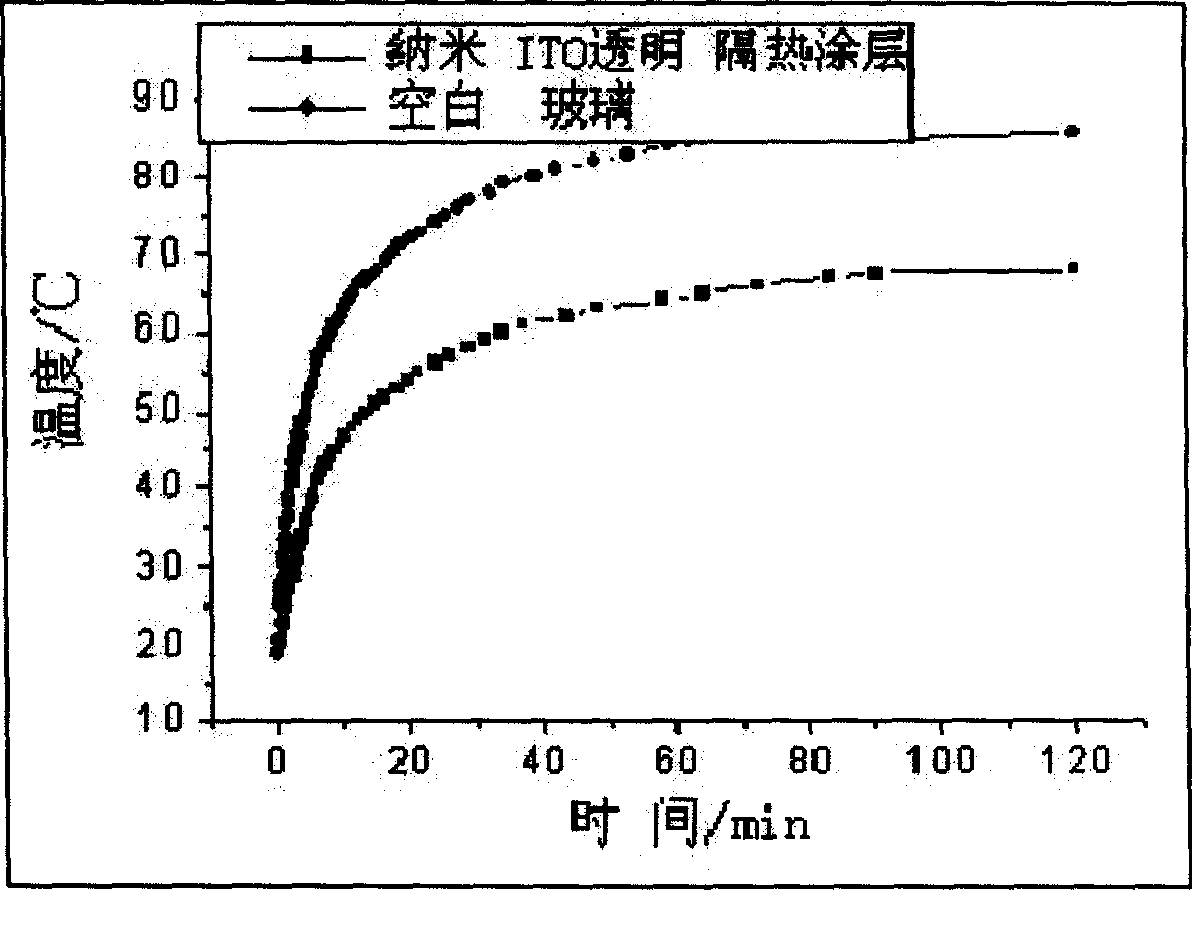

Image

Examples

Embodiment 1

[0016] A kind of heat insulating coating for transparent glass, its formula ratio is (percentage by weight):

[0017] Modified acrylic resin 70 Indium tin oxide 10

[0018] Isopropyl acetate 10 Benzene-free thinner JW 5

[0019] Diethylene glycol monoethyl ether acetate 3 UV absorber UV-9 2

[0020] Ultraviolet absorber UV-9 and indium tin oxide are mined in nanometer scale.

[0021] A method for manufacturing a transparent glass coating. Firstly, raw materials are weighed in proportion, and then film-forming substances and modified acrylic resin are added into a dispersing bucket. When the stirring speed of a mixer is 300-400 rpm, add oxidation Indium tin, isopropyl acetate, benzene-free thinner JW, diethylene glycol monoethyl ether acetate, then adjust the speed to 900-1100 rpm, stir at high speed for 15 minutes, add ultraviolet absorber UV-9, and stir again In 20 minutes, the finished product can be made.

[0022] Mixer model: TFJ-200;

[0023] Manufacturer: Xinxu Chem...

Embodiment 2

[0027] Its formula ratio:

[0028] Modified acrylic resin 68 Indium tin oxide 10

[0029] Isopropyl acetate 2 Benzene-free thinner JW 5

[0030] Diethylene glycol monoethyl ether acetate 3 UV absorber UV-9 2

Embodiment 3

[0032] Its formula ratio:

[0033] Modified acrylic resin 72 Indium tin oxide 9

[0034] Isopropyl acetate 9 Benzene-free thinner JW 5

[0035] Diethylene glycol monoethyl ether acetate 3 UV absorber UV-9 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com