Regenerated polyethylene composition and preparation method thereof

A technology for recycled polyethylene and composition, which is applied in the field of recycled polyethylene composition and its preparation, can solve the problems of unsatisfactory processing performance, melt strength and elongation at break of recycled polyethylene pipes, and can expand the scope of use, The effect of reducing plastic cost and improving melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

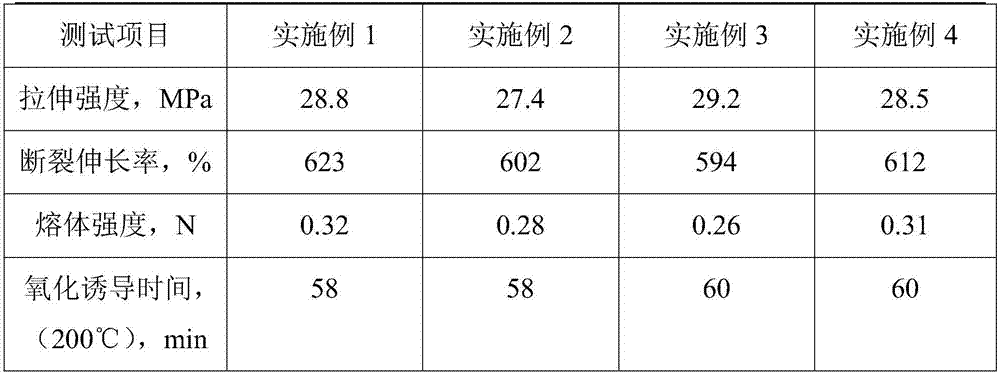

Examples

Embodiment 1

[0019] A recycled polyethylene composition is made from the following raw materials in parts by weight:

[0020] 56 parts of PE bottle cap material, 6 parts of PE large hollow material, 24 parts of mica, 12 parts of talcum powder, 3 parts of maleic anhydride grafted polyethylene, 7 parts of polyethylene paraffin and 8 parts of glycerol monostearate.

[0021] The preparation method comprises the following steps:

[0022] 1) Weigh the PE bottle cap material, PE large hollow material, mica, talc powder, maleic anhydride grafted polyethylene, polyethylene paraffin and glycerol monostearate according to the above weight, and put them into a high-speed mixer to stir and mix , the stirring speed is 2000 rpm, the stirring time is 11 minutes, and the stirring temperature is 102° C. to obtain a mixed material;

[0023] 2) Add the uniformly mixed materials into a twin-screw extruder, melt, plasticize, extrude, and granulate at a processing temperature of 216°C to obtain the product.

Embodiment 2

[0025] A recycled polyethylene composition is made from the following raw materials in parts by weight:

[0026] 50 parts of PE bottle cap material, 10 parts of PE large hollow material, 15 parts of mica, 20 parts of talcum powder, 2 parts of maleic anhydride grafted EPDM rubber, 5 parts of polyethylene paraffin and 4 parts of acetyl triethyl citrate .

[0027] The preparation method comprises the following steps:

[0028] 1) Weigh the PE bottle cap material, PE large hollow material, mica, talcum powder, maleic anhydride grafted EPDM rubber, polyethylene paraffin and acetyl triethyl citrate according to the above weight, and put them into high-speed mixing Machine stirring and mixing, the stirring speed is 1500 rpm, the stirring time is 10 minutes, and the stirring temperature is 110°C to obtain a mixed material;

[0029] 2) Put the uniformly mixed material into a twin-screw extruder, melt, plasticize, extrude, and granulate at a processing temperature of 210°C to obtain th...

Embodiment 3

[0031] A recycled polyethylene composition is made from the following raw materials in parts by weight:

[0032] 60 parts of PE bottle cap material, 5 parts of PE large hollow material, 30 parts of mica, 10 parts of talcum powder, 5 parts of maleic anhydride grafted polyethylene, 10 parts of polyethylene paraffin, 4 parts of acetyl triethyl citrate and boric acid 8 parts of ester.

[0033] The preparation method comprises the following steps:

[0034] 1) Weigh the PE bottle cap material, PE large hollow material, mica, talcum powder, maleic anhydride grafted polyethylene, polyethylene paraffin, acetyl triethyl citrate and borate according to the above weight, and put it into the high-speed Stir and mix with a mixer, the stirring speed is 2500 rpm, the stirring time is 16 minutes, and the stirring temperature is 120°C to obtain a mixed material;

[0035] 2) Put the uniformly mixed material into a twin-screw extruder, melt, plasticize, extrude, and granulate at a processing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com