A Bragg grating external cavity laser module beam combining device and beam combining method

A Bragg grating and laser technology, applied in the field of lasers, can solve the problems of deviation, difficult detection or judgment, and reduction of beam quality and power, and achieve the effects of high output power, fast judgment and detection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

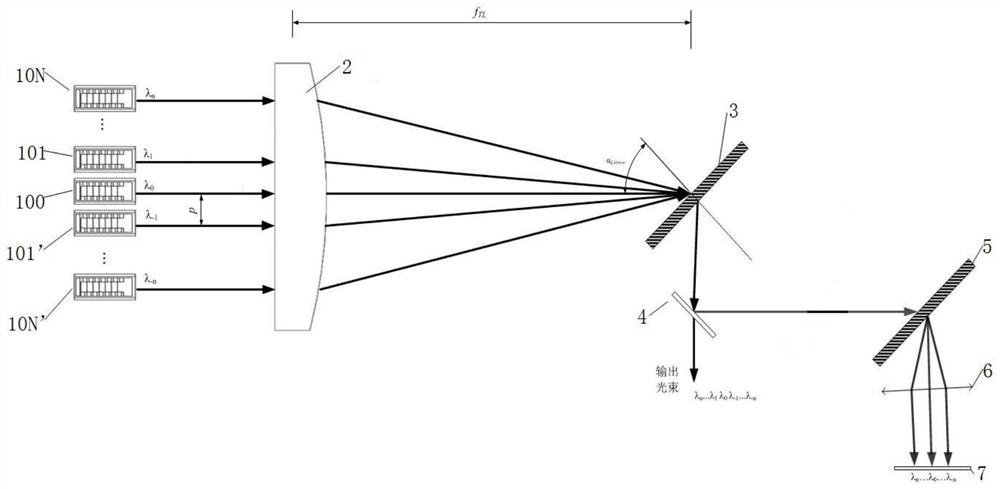

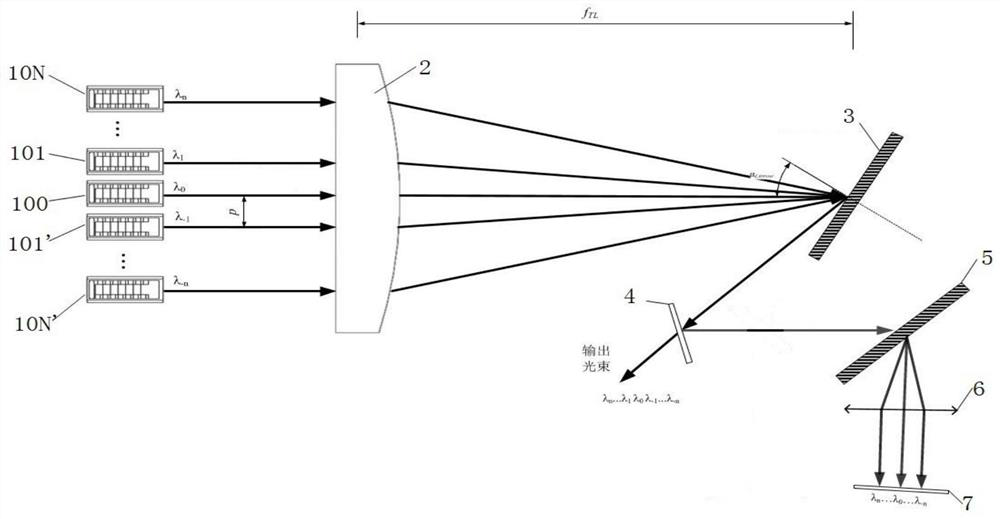

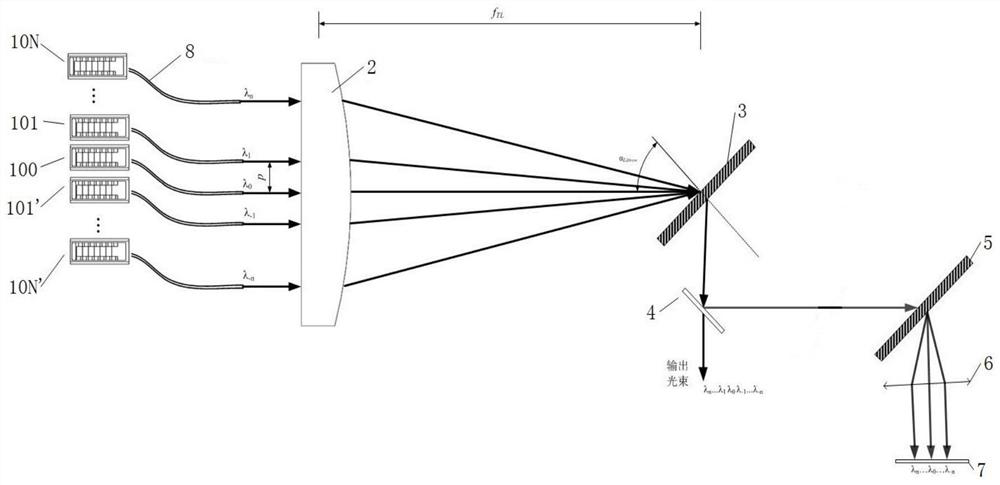

[0063] The VBG grating external cavity laser module beam combiner of this embodiment, such as Figure 1 to Figure 4 As shown, it includes a plurality of light emitting modules 1, a focusing optical element 2, a beam combining element 3, a light splitting element 4, a dispersion element 5, a transformation optical element 6, an image acquisition mechanism 7 and a temperature control device 17, wherein A plurality of light-emitting modules 1 are arranged at intervals in an array to emit laser light of different wavelengths, and the laser light is incident on the Bragg grating 16 to achieve wavelength locking. 0 light-emitting module) as the reference light-emitting module 100, the wavelength of the emitted laser light is λ 0 , the other light-emitting modules 1 are symmetrically arranged on the upper and lower sides of the reference light-emitting module 100, and the intervals between the light-emitting modules 1 are equal. on the beam element 3; the output light of the light-e...

Embodiment 2

[0106] The beam combining method of this implementation is based on the Bragg grating external cavity laser module beam combining device in Embodiment 1, such as Figure 1 to Figure 10 shown, including the following steps:

[0107] Acquire an image, the image includes a reference block and several blocks to be compared, wherein the reference block corresponds to the reference light-emitting module 100 (such as figure 1 λ 0 The output wavelength (λ 0 ) laser, the block to be compared with other light-emitting modules (such as figure 1 λ 1 -λ N and lambda -1 -λ -N The output wavelength lasers of the light-emitting module) correspond one-to-one;

[0108] Based on the reference block, obtaining the preset block range corresponding to each block to be compared;

[0109] Comparing any block to be compared with its corresponding preset block range;

[0110] Judging whether the tiles to be compared fall within the respective corresponding preset tile ranges;

[0111] If the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com