Three-phase high-speed rotation positive electrode driver

A high-speed rotation and drive technology, which is applied in AC motor control, radiological diagnostic equipment, medical science, etc., can solve problems such as limited reconstruction space, crack damage on the target surface, and irregular scattering of rays to improve imaging effects , prolong the service life, the effect of smooth current transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

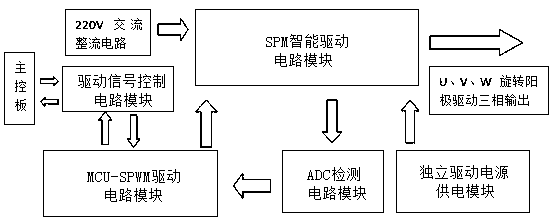

[0040] Such as figure 1 As shown, a three-phase high-speed rotating anode driver is mainly composed of an MCU-SPWM drive circuit module, an SPM intelligent drive circuit module, an ADC detection circuit module, an independent drive power supply module and a drive signal control circuit module; the drive The signal control circuit module, the MCU-SPWM drive circuit module, and the SPM intelligent drive circuit module are connected sequentially; the SPM intelligent drive circuit module is also connected with the ADC detection circuit module and the independent drive power supply module respectively; the ADC detection The circuit module is also connected with the MCU-SPWM driving circuit module.

[0041] exist figure 1 Among them, the main control board inputs drive control instructions to the MCU-SPWM drive circuit module through the drive signal control circuit module, and the external mains supplies the drive voltage to the SPM intelligent drive circuit module after passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com