Fine sand recycling system and working method thereof

A recovery system and technology for fine sand, applied in separation methods, chemical instruments and methods, wet separation, etc., can solve the problem of less powder and fine particles, and achieve the effect of increasing the content, improving the recovery rate of fine sand, and strengthening the fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

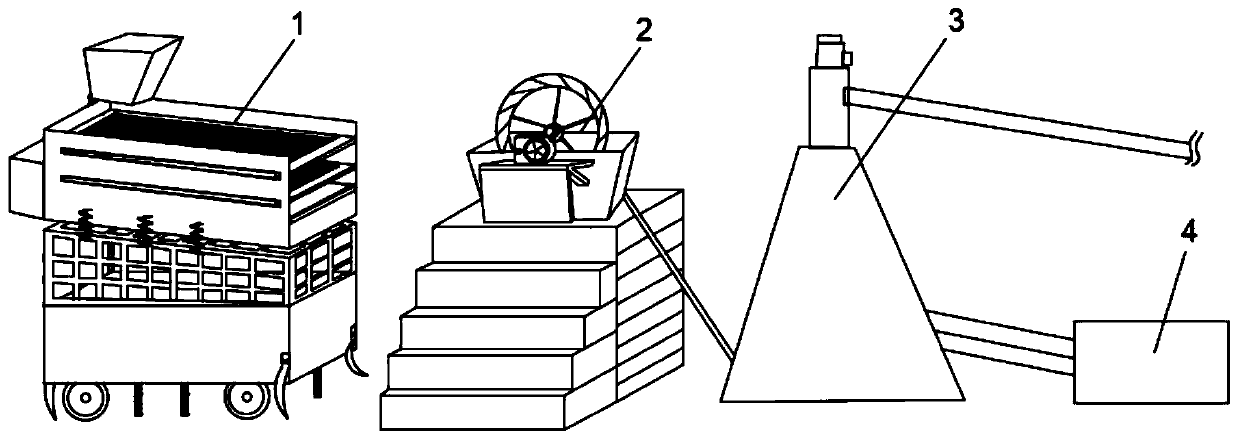

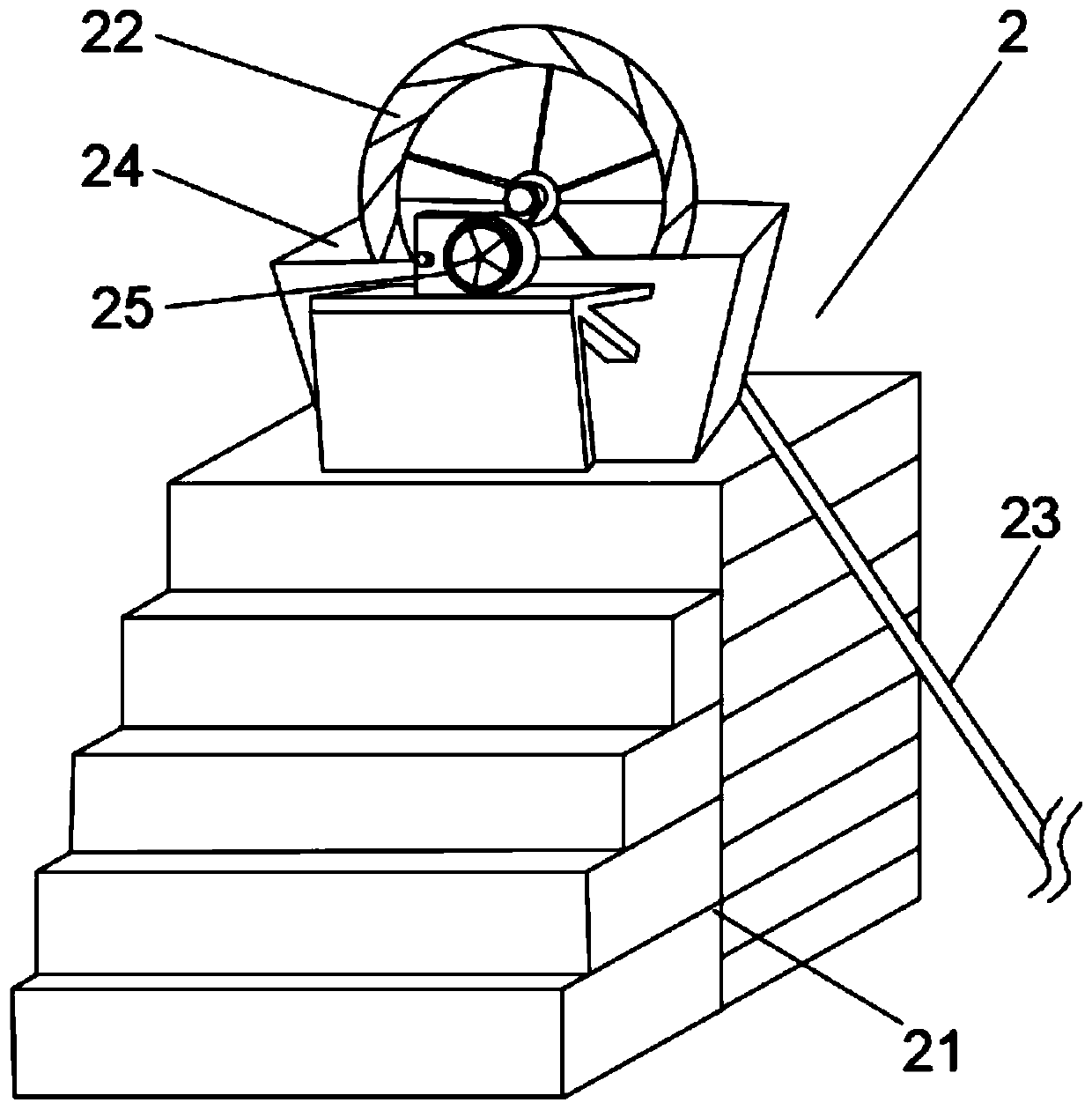

[0029]A silt fine sand recovery system, fine sand is separated and recovered from the gravel mixture of stone, coarse sand, medium coarse sand and fine sand, the recovery system mainly includes a sand screening mechanism 1, a sand washing device 2, Fine sand precipitation recovery device 3 and waste residue pool 4;

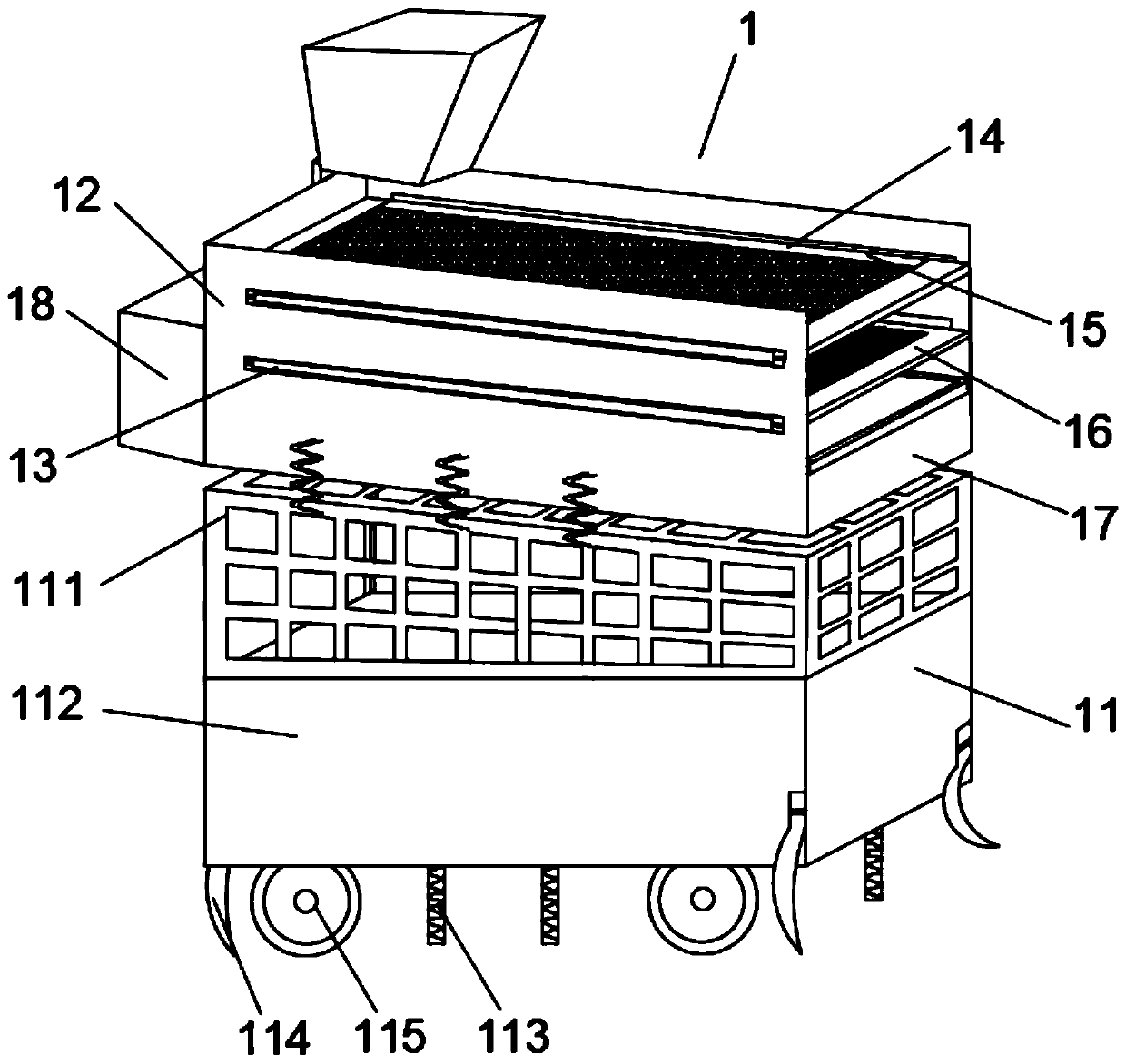

[0030] The sand screening mechanism 1 comprises a mobile base 11, a screening frame 12, a support drum 13, a coil belt 14, a first sieve layer 15, a second sieve layer 16, a sand recovery box 17 and a vibrator 18; wherein The mobile base 11 is installed under the screening frame 12 to support the screening frame 12; the screening frame 12 is surrounded by two relatively parallel long side plates, short side plates and bottom plates to form an open frame-like cavity structure , the short side plate is vertically connected between the two long side plates, and a feeding hopper is installed on the outer side of the short side plate, the feeding hopper is installed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com