Preparation method of a flame-retardant and electromagnetic shielding sandwich insulation material

A thermal insulation material and electromagnetic shielding technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of complex process, high cost, can not meet the needs of production, etc., to simplify the processing technology , excellent flame retardancy, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

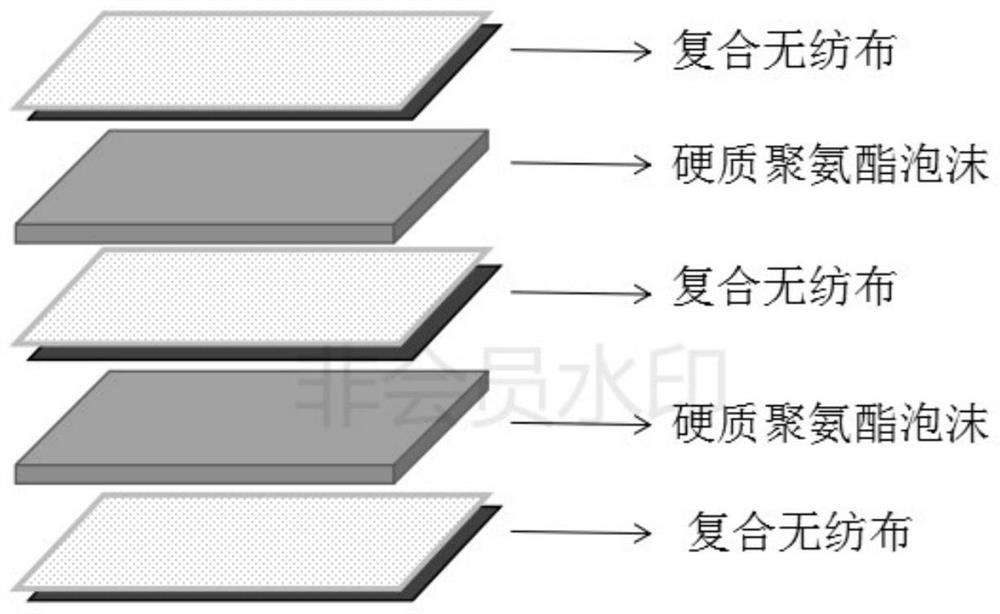

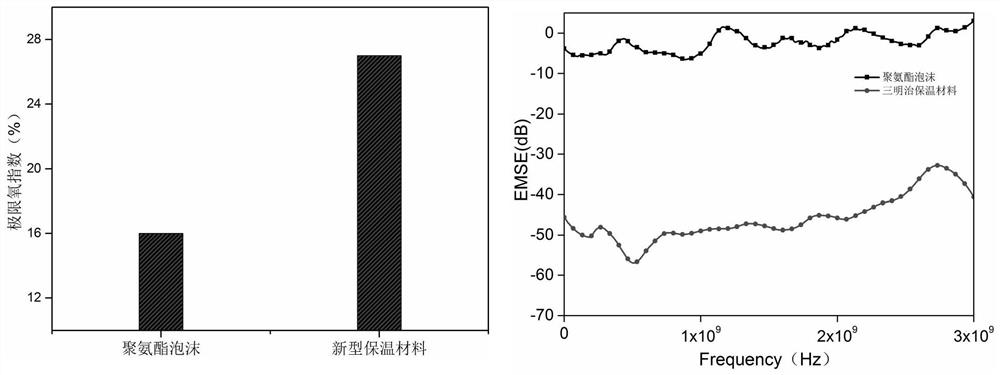

[0026] Such as figure 1 As shown, a novel flame-retardant and electromagnetic shielding sandwich insulation material provided by the present invention includes composite non-woven fabric and rigid polyurethane foam, the composite non-woven fabric is provided with upper, middle and lower layers, and rigid polyurethane foam It is filled between two composite non-woven fabrics, and the composite non-woven fabric is composed of carbon fiber cloth, adhesive, and sulfonamide cloth. Specifically, the adhesive is set to be water-based polyurethane.

[0027] The preparation method includes the following steps: Step 1: Apply the adhesive evenly on the carbon fiber cloth and the sulfonamide cloth, compound the two together, dry them in a constant temperature and humidity environment to prepare a composite Non-woven fabric; Step 2: After stirring the polyether polyol and phosphorus-based flame retardant evenly, then add isocyanate for secondary stirring to prepare rigid polyurethane foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com