Halogen-free flame-retardant heat-resistant water-soluble epoxy resin, composition, preparation method and application thereof

An epoxy resin, water-soluble technology, applied in the synthesis and application of epoxy resin, can solve the problems that the comprehensive performance cannot meet the copper clad laminate, low cross-linking density, low mechanical strength, etc., and achieves good environmental performance and heat resistance. High and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

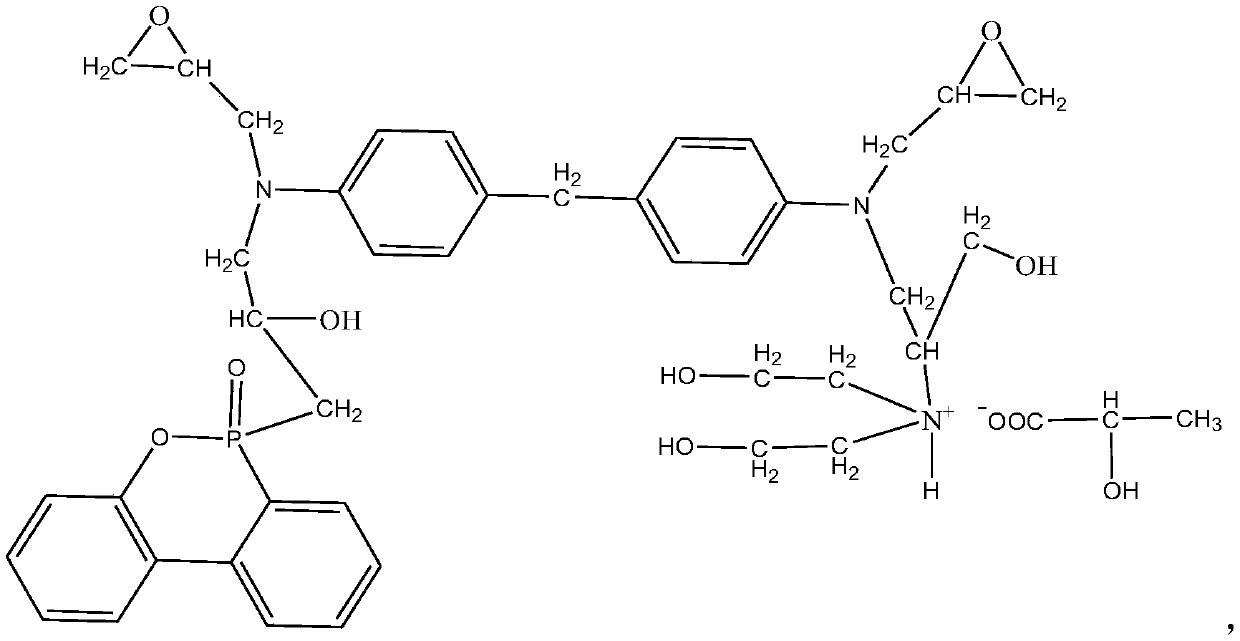

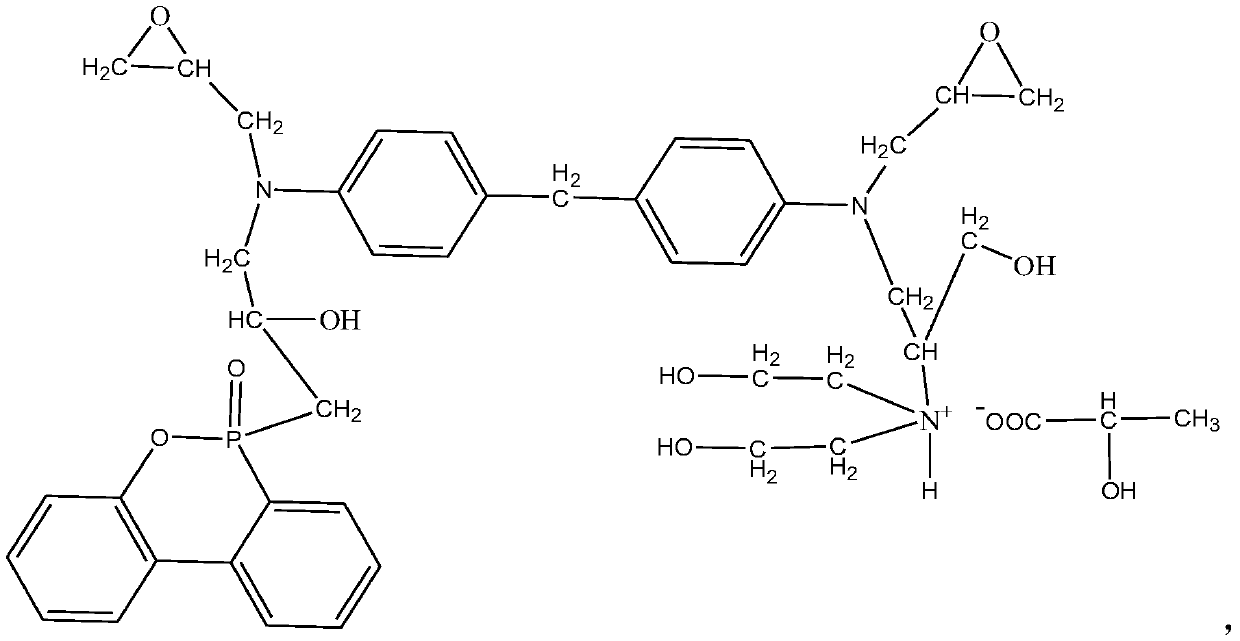

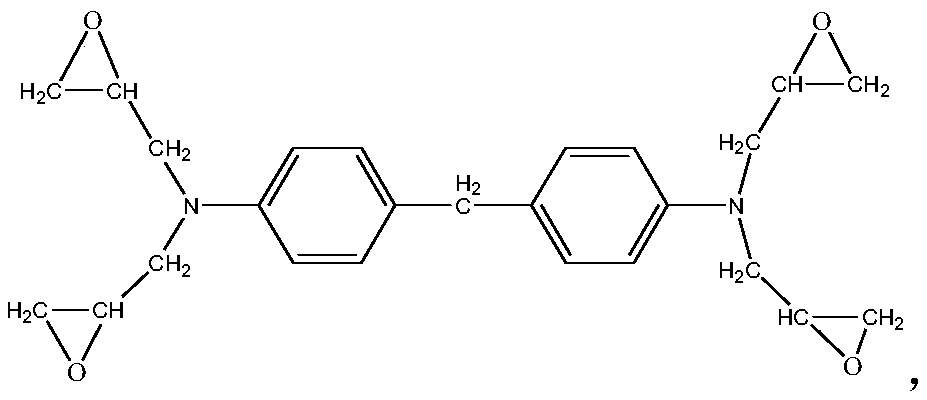

[0041] A halogen-free flame-retardant and hot-water-resistant epoxy resin, the chemical structural formula of the halogen-free flame-retardant and hot-water-resistant epoxy resin is:

[0042]

[0043] The halogen-free flame retardant and heat-resistant water-soluble epoxy resin is composed of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin and 9,10-dihydro-9-oxa-10-phosphaphenanthrene- 10-oxide (referred to as DOPO) is heated under the action of 2-ethyl-4-methylimidazole to generate phosphorus-containing epoxy resin, then reacted with diethanolamine, added lactic acid, and finally added (appropriate amount) water and stirred evenly. get. The halogen-free flame-retardant and heat-resistant water-soluble epoxy resin is light yellow liquid, and when the solid content is 75% by mass, the viscosity at normal temperature is 800-1200mpas.

Embodiment 4

[0045] The preparation method of the halogen-free flame-retardant and heat-resistant water-soluble epoxy resin is: add 60 parts by mass of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin liquid into the reactor, and raise the temperature to 140°C , add 20 mass parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO for short), stir to make 9,10-dihydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide (DOPO for short) is dissolved in the liquid of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin, and then 0.02 parts by mass of 2-ethyl-4-methylimidazole is added, Raise the temperature to 150°C and react for 4 hours, then cool down to 80°C, add 5 parts by mass of diethanolamine, stir and react for 4 hours, then cool down to 60°C, add 4 parts by mass of lactic acid, and finally add an appropriate amount of water, stir evenly, and make a solid A halogen-free flame-retardant and heat-resistant water-soluble epoxy resin with a mass percentage of 75% (pale yellow l...

Embodiment 5

[0047] The preparation method of the halogen-free flame-retardant and heat-resistant water-soluble epoxy resin is as follows: 70 parts by mass of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin liquid is added to the reactor, and the temperature is raised to 140°C , add 25 mass parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO for short), stir to make 9,10-dihydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide (DOPO for short) is dissolved in the liquid of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin, and then 0.1 parts by mass of 2-ethyl-4-methylimidazole is added, Raise the temperature to 180°C for 1 hour, then lower the temperature to 120°C, add 10 parts by mass of diethanolamine, stir and react for 2 hours, then cool down to 60°C, add 8 parts by mass of lactic acid, and finally add an appropriate amount of water, stir evenly, and make a solid The mass percent content is 75% (pale yellow liquid) halogen-free flame-retardant heat-resistant wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com