Pipeline dredging robot

A robot and pipeline technology, applied in the direction of cleaning sewer pipes, instruments, waterway systems, etc., to achieve the effect of easy disassembly and replacement, increase working time, and reduce load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

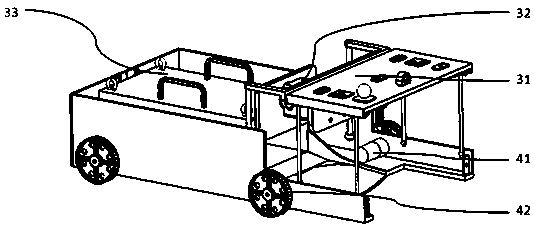

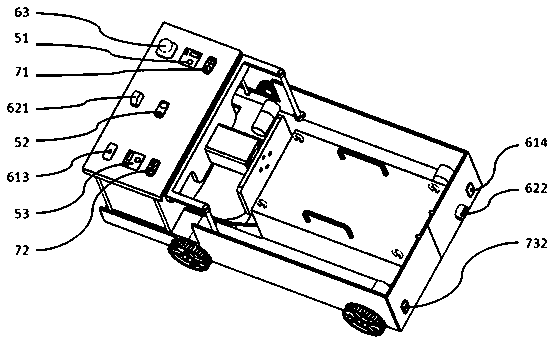

[0022] The present invention will be further described below in conjunction with the accompanying drawings to specifically illustrate the technical solution.

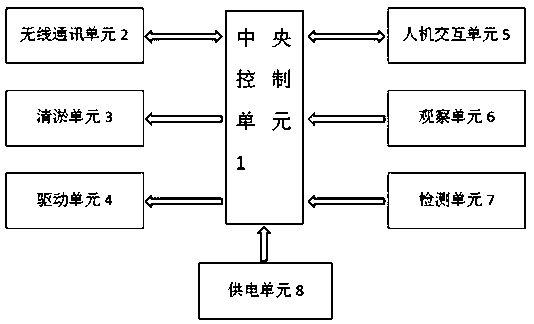

[0023] like figure 1 As shown, a pipeline dredging robot of the present invention is connected by a central control unit 1 with a wireless communication unit 2, a dredging unit 3, a drive unit 4, a human-computer interaction unit 5, an observation unit 6, a detection unit 7, and a power supply unit 8. Realize the information collection and processing control of each unit, and realize the dredging function inside the pipeline.

[0024] Among them, the robot central control unit 1 adopts a micro-controller chip to complete data collection and processing, and control each unit to complete related functions.

[0025] The robot wireless communication unit 2 realizes various wireless communications through the wireless module. The image acquisition system uses a wireless video screen transmission module, and the operation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com