High-purity conjugated linoleic acid yak yogurt and making method thereof

A pure conjugated linoleic acid, conjugated linoleic acid technology, applied in milk preparations, dairy products, applications, etc., can solve less than one-third of the recommended amount, increase the cost of conjugated linoleic acid, etc. problems, to achieve the effect of simple operation, increasing the content of conjugated linoleic acid, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention provides a method for preparing high-purity conjugated linoleic acid yak yogurt, which mainly consists of an enzymatic hydrolysis link and a fermentation link, wherein the enzymatic hydrolysis link includes:

[0022] S1. Mix the yak milk that has been sterilized by filtration and porcine pancreatic lipase at 35-40°C for 3-8 hours to obtain the first enzymatic hydrolyzate;

[0023] S2. Heat the first enzymatic hydrolysis solution to 90-100°C and maintain it for 10-15 minutes to inactivate;

[0024] S3. Mix the inactivated first enzymatic hydrolyzate with protease at 38-43°C for 2-5 h to obtain the second enzymatic hydrolyzate;

[0025] S4. Heat the second enzymatic hydrolysis solution to 90-100°C and maintain it for 10-15 minutes to inactivate it.

[0026] Yak is the main livestock species in the Qinghai-Tibet Plateau, and the yak milk it produces accounts for 90% of the milk consumption in the Qinghai-Tibet Plateau. Compared wit...

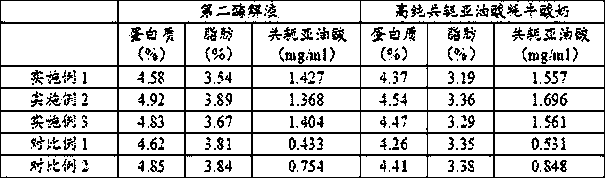

Embodiment 1

[0040] This embodiment provides a kind of high-purity conjugated linoleic acid yak yoghurt, and its preparation method is as follows:

[0041] S1. Mix the filtered sterilized yak milk and porcine pancreatic lipase for 8 h at 40°C to obtain the first enzymatic hydrolyzate; the dosage of porcine pancreatic lipase is 10 kg per 100 kg of yak milk DCU. The fat content of the first enzymolysis solution was 4.58wt%.

[0042] S2. Heat the first enzymatic hydrolysis solution to 100°C and maintain it for 10 minutes for inactivation.

[0043] S3. Mix the inactivated first enzymatic hydrolyzate with protease for 5 h at 40°C to obtain the second enzymatic hydrolyzate; the dosage of protease is 6 DCU per 100 kg of yak milk. Protease is alkaline protease. The protein content in the second enzymolysis solution was 3.54wt%.

[0044] S4. Heat the second enzymatic hydrolysis solution to 100°C for 10 minutes to inactivate.

[0045] S5. Mix the inactivated second enzymolysis solution with xyl...

Embodiment 2

[0048] This embodiment provides a kind of high-purity conjugated linoleic acid yak yoghurt, and its preparation method is as follows:

[0049] S1. Mix the filtered sterilized yak milk and porcine pancreatic lipase for 3 h at 35°C to obtain the first enzymatic hydrolyzate; the dosage of porcine pancreatic lipase is 5% per 100 kg of yak milk DCU. The fat content of the first enzymolysis solution was 4.92wt%.

[0050] S2. Heat the first enzymatic hydrolysis solution to 90°C and maintain it for 15 minutes to inactivate it.

[0051] S3. Mix the inactivated first enzymatic hydrolyzate with protease for 2 h at 43°C to obtain the second enzymatic hydrolyzate; the dosage of protease is 2 DCU per 100 kg of yak milk. The protease is trypsin. The protein content in the second enzymolysis solution was 3.89wt%.

[0052] S4. Heat the second enzymatic hydrolysis solution to 90°C and maintain it for 15 minutes to inactivate it.

[0053] S5. Mix the inactivated second enzymolysis solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com