A construction method for track concrete

A construction method and concrete technology, applied in the directions of roads, roads, pavements, etc., can solve problems such as inability to process shotcrete on the track, and achieve the effects of improving quality and construction efficiency, increasing surface roughness, and increasing compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

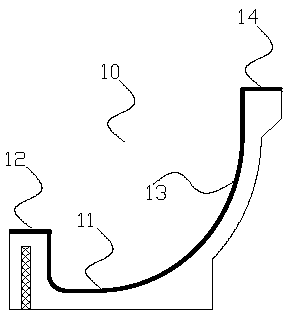

[0016] Such as figure 1 As shown, this embodiment provides a construction method for track concrete, including the following steps: Step S1: After the concrete spraying of the track 10 is completed, scrape off the floating material and excess spray material on the track 10 surface, and sequentially Scrape the concrete on the surface of each section of the track until it is flush with the leveling pipe on the track 10; step S2: perform the first troweling and leveling on the surface of the track 10, and wait for the first troweling and leveling to be completed Finally, remove the upper eaves formwork and the lower eaves formwork of the race track 10, and process the upper cornice 14 and the lower cornice 12 of the race track 10; step S3: take out the Step S4: After the filling of the leveling tube is completed, the surface of the track 10 is smoothed and leveled for the second time, and the surface of the track 10 is roughened.

[0017] The construction method of the track con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com