Vibration prediction method of completion pipe string of high-temperature, high-pressure and high-gas-rate well

A well completion string, high temperature and high pressure technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as casing collapse, high risk, failure of tubing string, etc., and achieve fast calculation and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

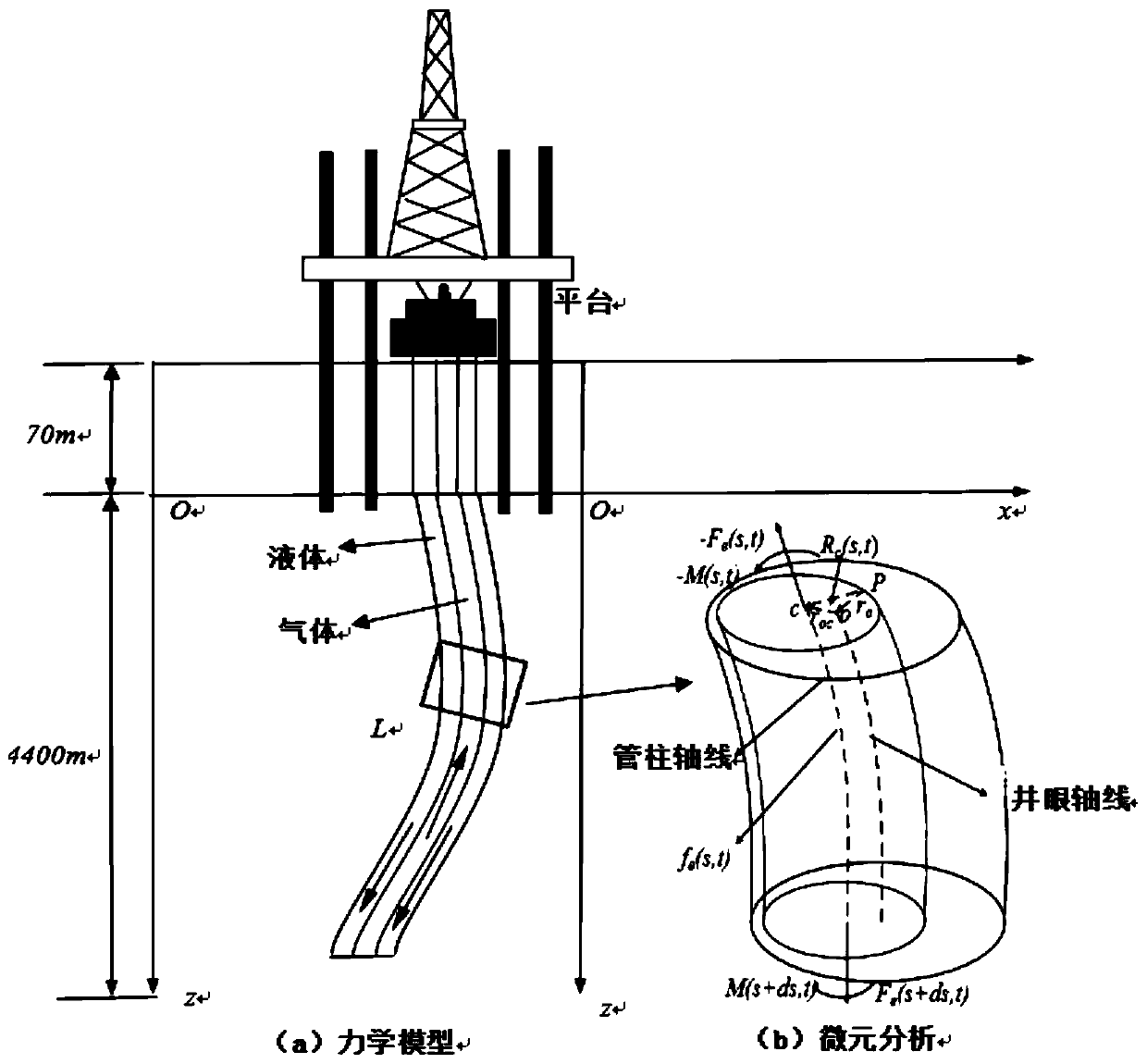

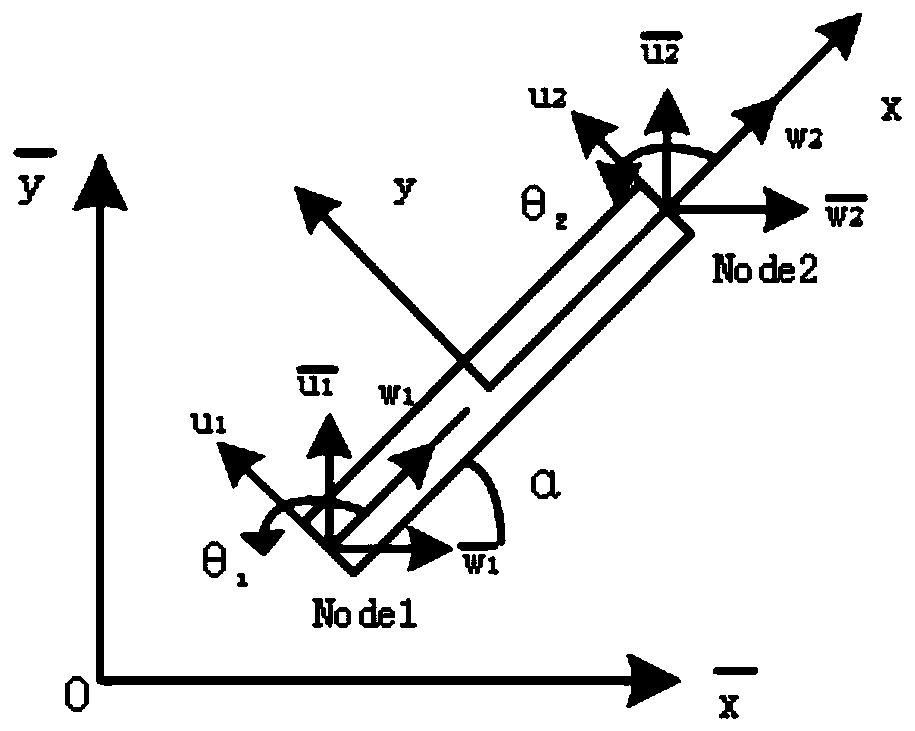

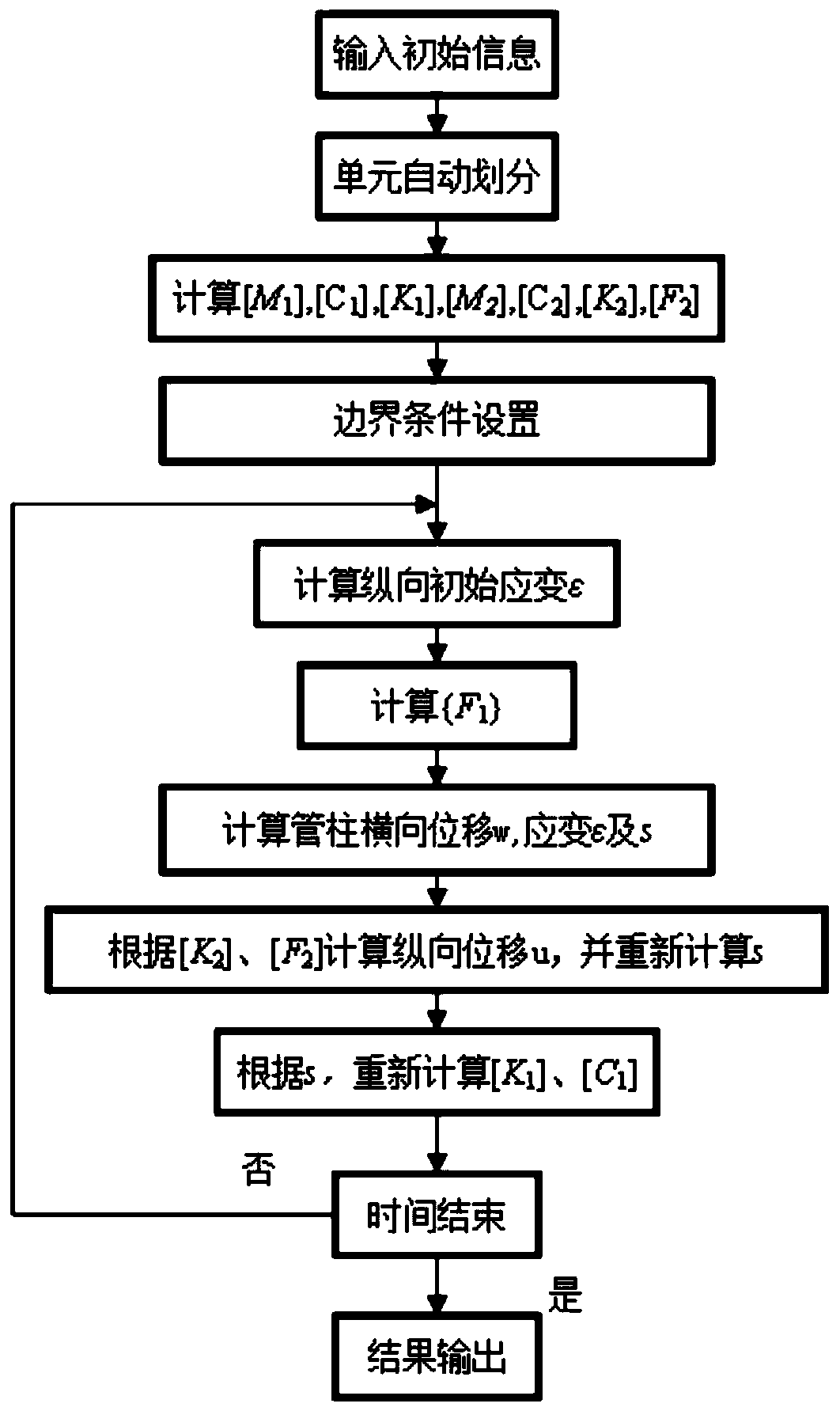

Method used

Image

Examples

Embodiment

[0123] Taking the A3 gas well in the Dongfang 13-2 gas field in the Yinggehai Basin as an example, the calculation parameters of this well are shown in Table 1:

[0124] Table 1 Calculation parameters of gas well A3 in Dongfang 13-2 gas field

[0125] parameter value parameter value Tube length (m) 3900 Time step (s) 0.001 String inner diameter (m) 0.1003 Number of division units 1000 String Outer Diameter (m) 0.1143 unit length 3.9 Casing inner diameter (m) 0.1778 (7 inch tailpipe) coefficient of friction 0.3 Casing outer diameter (m) 0.1658 Tubing density (kg / m 3 )

7850 Fluid velocity (m / s) 10.0 Fluid density (kg / m 3 )

750 Calculation time (s) 10 Well inclination (°) 43.44 Production packer position (m) 3588 Middle packer position (m) 3900 tubing material 15.1ppf13cr-L80 Tensile strength (MPa) 665

[0126] Gas well A3 in Dongfang 13-2 gas field is a directional well,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com