Glass furnace temperature intelligent prediction control method based on attention mechanism and auto-encoder

A self-encoder and intelligent prediction technology, which is applied in temperature control, electric temperature control, non-electric variable control, etc., can solve problems such as temperature changes in the working environment, changes in kiln insulation performance, and difficulty in adapting to object parameters. Achieve the effect of intelligent predictive dynamic control, important market value, and glass quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

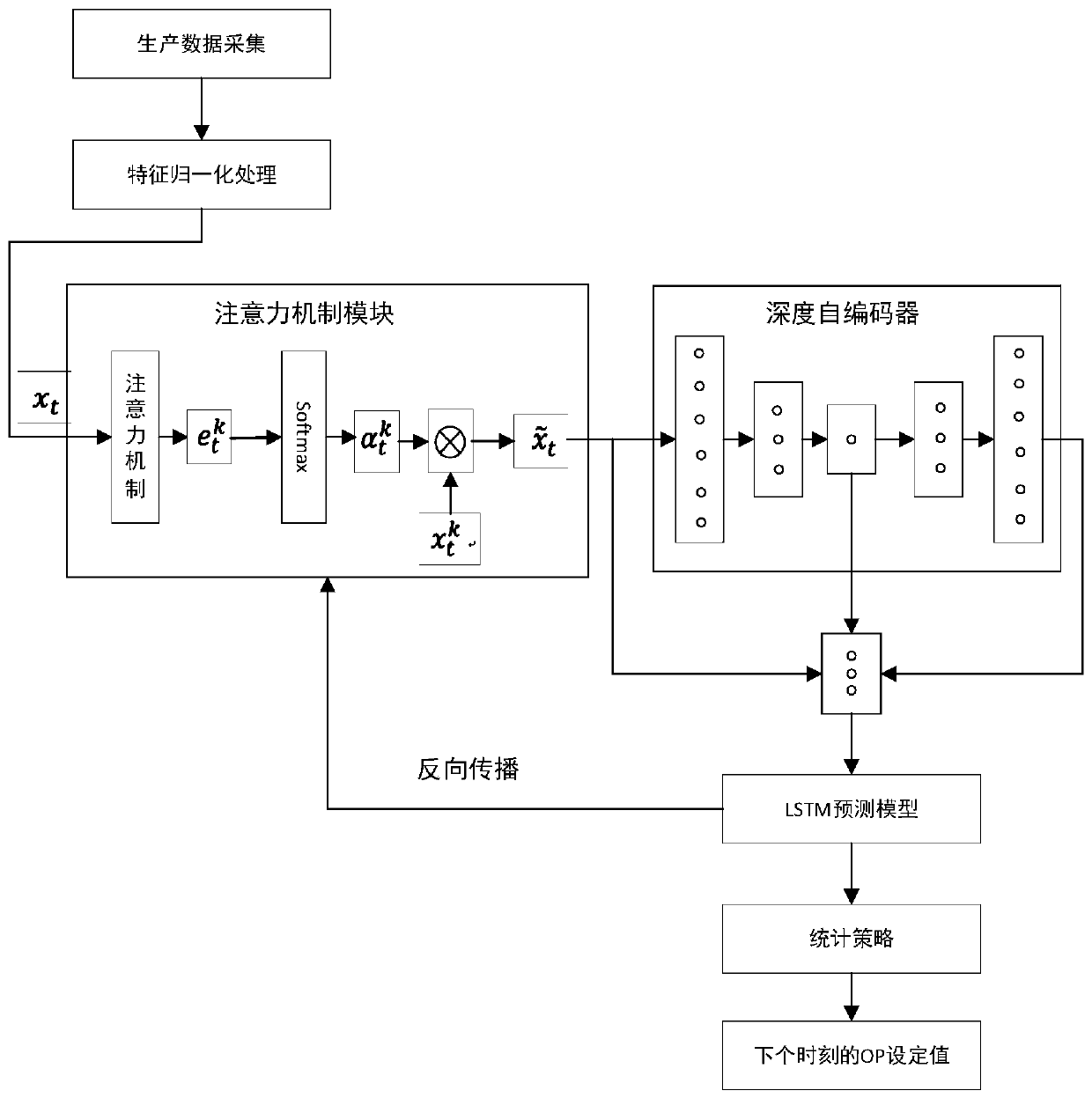

[0034] An embodiment of the present invention provides an intelligent predictive control method for glass furnace temperature based on an attention mechanism and an autoencoder, including the following steps:

[0035] Step (1): Data preprocessing: collecting historical production data related to the temperature prediction control of the pretreatment glass furnace.

[0036] Step (1.1): historical data collection of glass melting furnace

[0037] The present invention collects production information related to the temperature control of the glass furnace, because there are more than 1,000 sensors deployed on the glass melting furnace for detecting and adjusting variable indicators. After analysis, the characteristic data required by the present invention mainly include: glass melting furnace Real-time measured value of top temperature, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com