A new method of plugging leakage under pressure for gis equipment

A technology of plugging and equipment under pressure, which is applied in the setting of switchgear, electrical components, switchgear, etc. It can solve the problems of small plugging range, pipeline plugging, and small application range, so as to avoid secondary leakage and ensure Sealing performance, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] When there is one leakage point, the new pressurized leakage plugging method of GIS equipment of the present invention comprises the following steps:

[0038] The first step, cleaning: use the combination of detergent, surfactant and cleaning paper to clean the surface near the leakage of GIS equipment, then polish the cleaned part, and then use detergent, surfactant and cleaning paper for treatment , to complete the entire cleaning process.

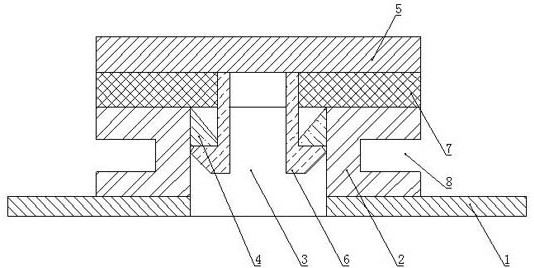

[0039] The second step, fix: take a special plugging device at the leak, first, place the locking base 1 at the leak point, and place the leak point in the air outlet 3 of the locking base 1, then, Use plugging glue to bond the locking base 1 to the surface of the leakage point of the GIS equipment, press for 5-6 minutes, and then use structural glue to fix the locking base 1 after the plugging glue is initially cured.

[0040] The third step is plugging: after the structural adhesive is fixed, fasten the locking buckle equipped ...

Embodiment 2

[0045] When there are multiple leak points, the new pressurized leak plugging method for GIS equipment of the present invention comprises the following steps:

[0046] The first step, cleaning: use the combination of detergent, surfactant and cleaning paper to clean the surface near the leakage of all GIS equipment, then polish the cleaned parts, and then use detergent, surfactant and cleaning paper after polishing Disposal to complete the entire cleaning process.

[0047] The second step, pretreatment: firstly use the gas catch method to gather the leakage points of the GIS equipment into one place. The leakage point is plugged, while the collection point is not plugged with plugging glue, so that the gas can escape from the collection point and the curing of the plugging glue at other leakage points is facilitated.

[0048] The third step, fixing: After the plugging glue at the other leaking points is cured, take a special plugging device at the collection point, first, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com