Electrostatic generator based on ultra-smooth material

A generator, electrostatic technology, applied in the direction of electrostatic generator/motor, generator/motor, electrical components, etc., can solve the problems of reducing output efficiency, reducing the service life of the generator, increasing the size of the external force driving the generator, etc. Increased output efficiency, low friction, optimized structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

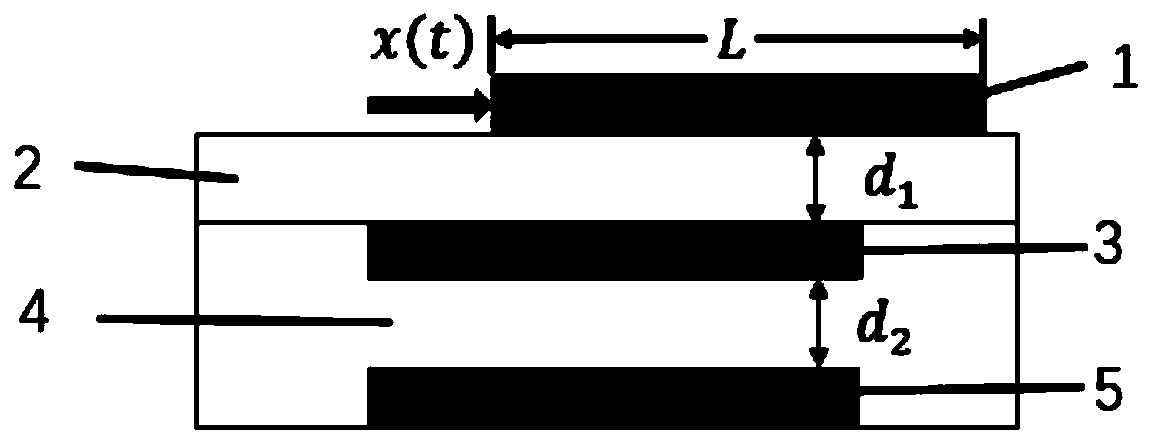

[0044] first combined with Figure 1-4 Explain the general power generation process of the electrostatic micro generator,

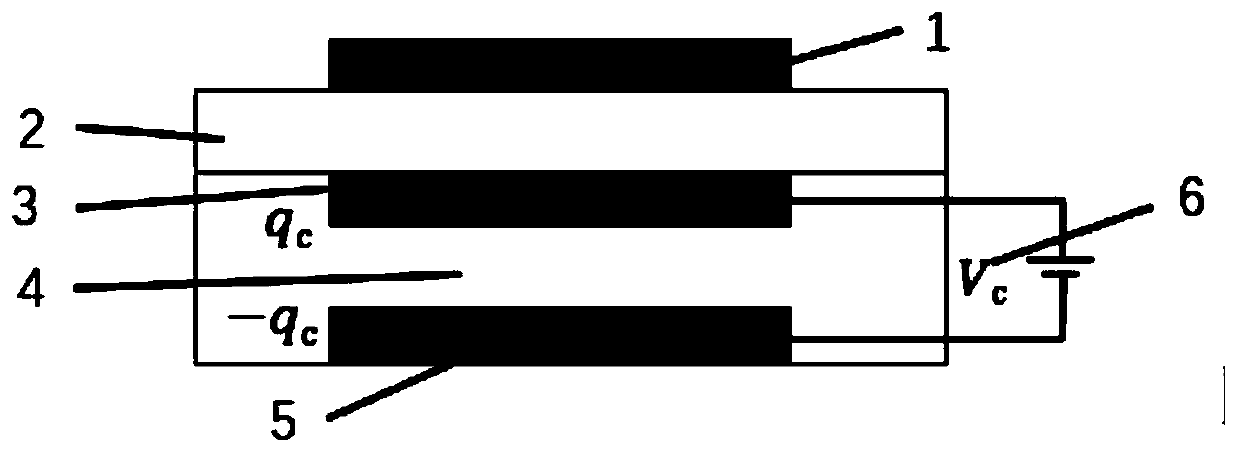

[0045] Charging process: as figure 2 As shown, an external power supply 6 is connected between the second conductive layer 3 and the third conductive layer 5, and the voltage is V c , so that the second conductive layer 3 and the third conductive layer 5 are charged with charges q of equal magnitude and opposite sign c .

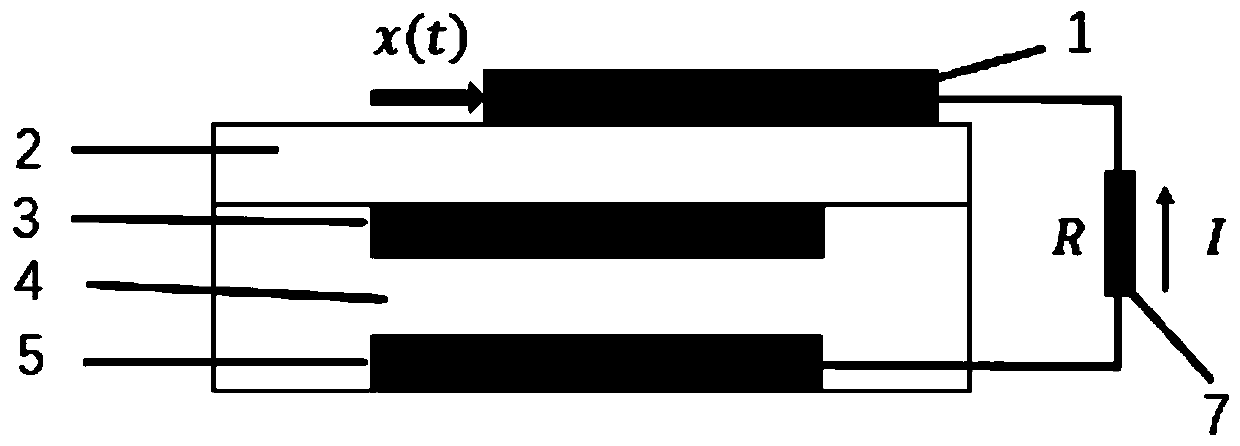

[0046] Balance process: if image 3 As shown, the first conductive layer 1 and the third conductive layer 3 are connected to form a loop.

[0047] Power generation process: such as image 3As shown, the first conductive layer 1 is moved to change the capacitance between the first conductive layer 1 and the second conductive layer 3 to generate an induced electromotive force to drive electrons to move and form a current.

[0048] The corresponding equivalent circuit diagram is as Figure 4 As shown, the capacitor C is formed betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com