Clutch apparatus for forging press with integral type clutch hub

A clutch device and clutch technology, applied in the field of forging presses, can solve the problems of difficult replacement of friction linings, reduction of air supply speed, difficulty of replacement and maintenance, etc., and achieve the goals of suppressing knocking, reducing air consumption, and reducing maintenance and repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

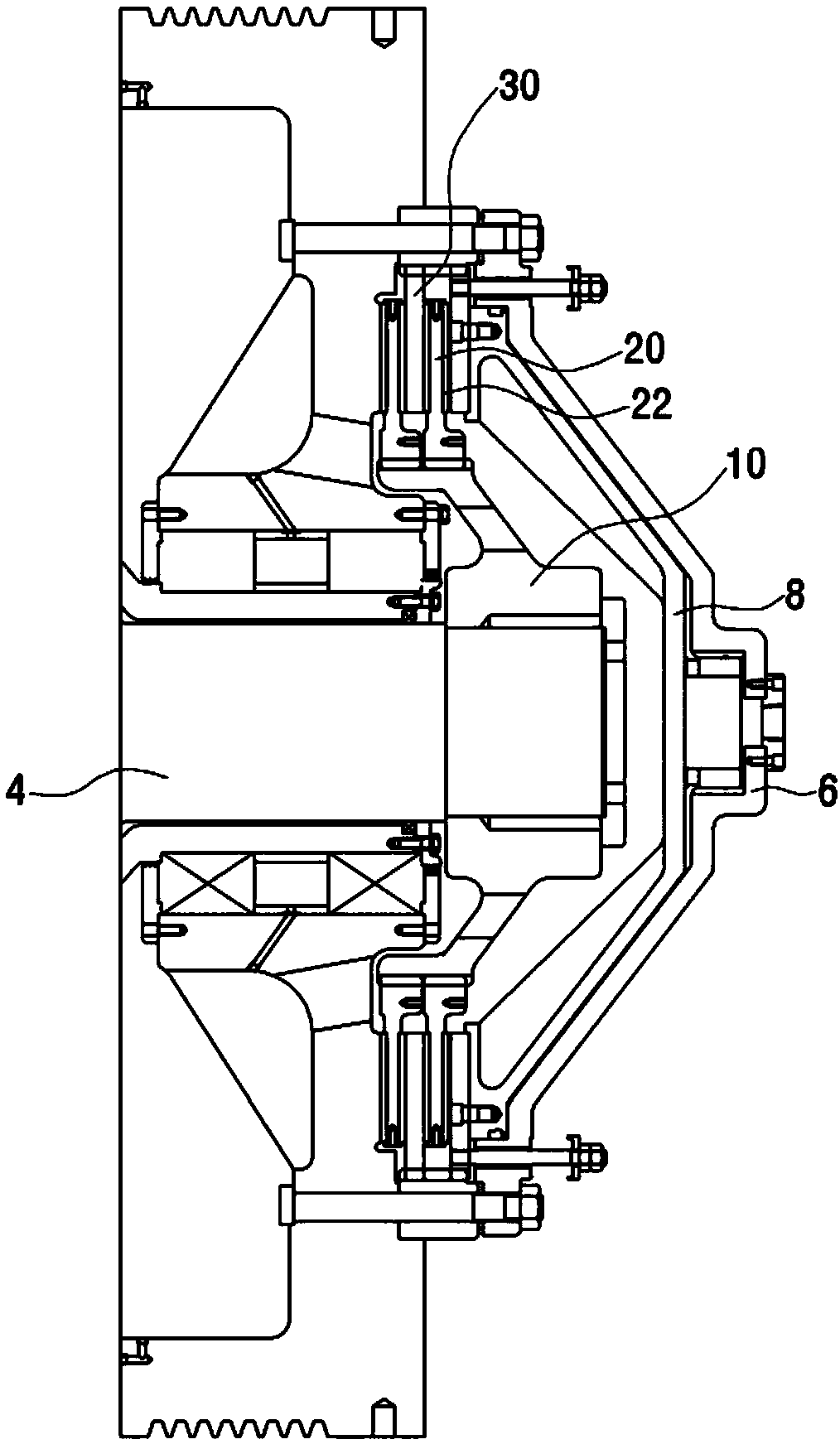

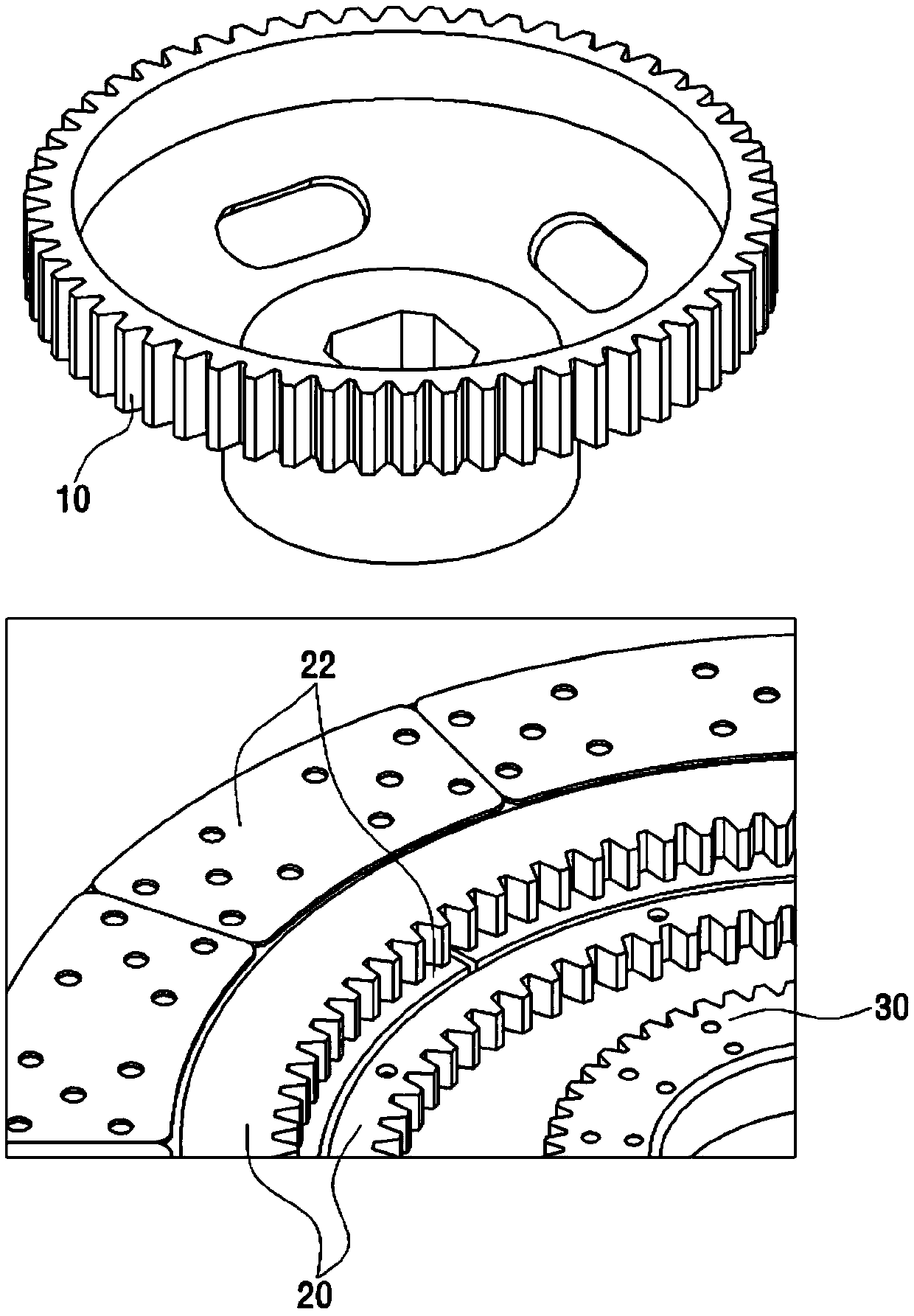

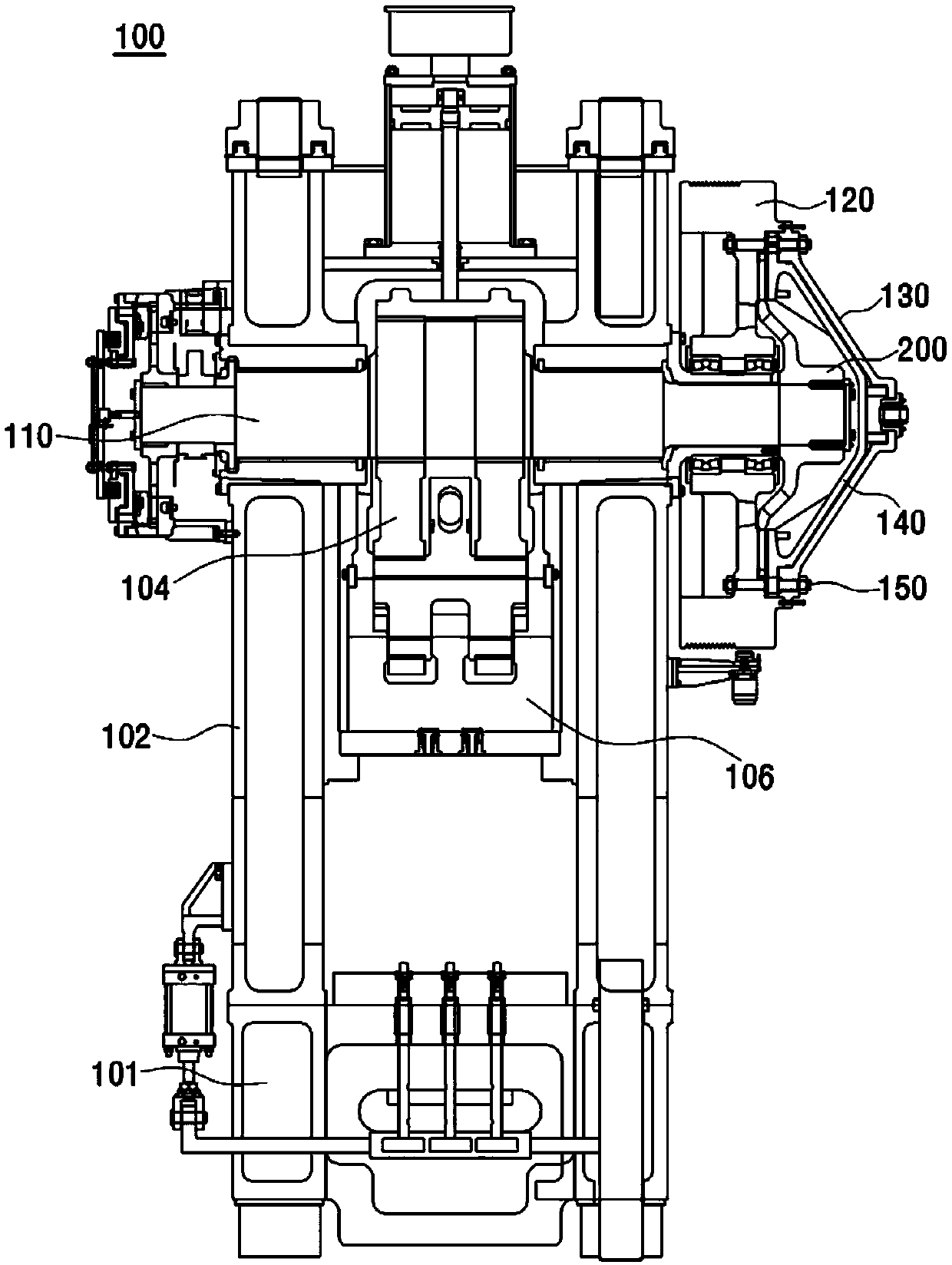

[0051] Next, the structure and effect of the clutch device of the integrated clutch hub for forging press according to the present invention will be described with reference to the drawings.

[0052] For a description of a particular embodiment shown in a drawing, the corresponding drawing is read, and the drawing is considered a part of the description of the entire invention. The mentioned directions or directivity are for convenience of description only, and are not intended to limit the scope of claims of the present invention in any way.

[0053] Specifically, terms showing positions such as "below, above, horizontal, vertical, upper side, lower side, upward, downward, upper, lower", or their derivatives (for example, "in a horizontal direction, downward side, upward "side", etc.), all should refer to the relevant description of the accompanying drawings. In particular, the relative terms are only used for convenience of description, and do not require that the device of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com