Rubber roller

A rubber roller and rubber technology, which is applied in the field of rubber rollers, can solve the problems affecting the service life and the production quality of composite films, and achieve the effect of reducing the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

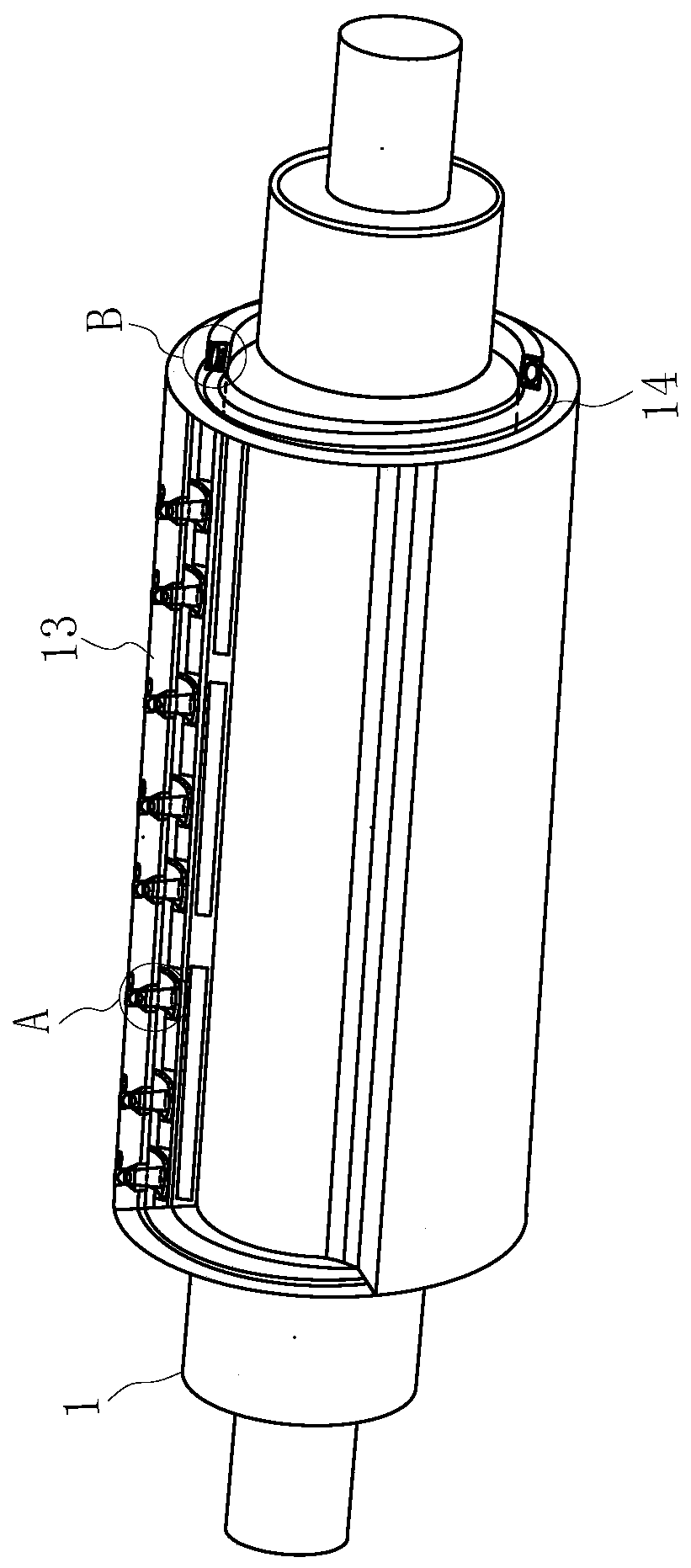

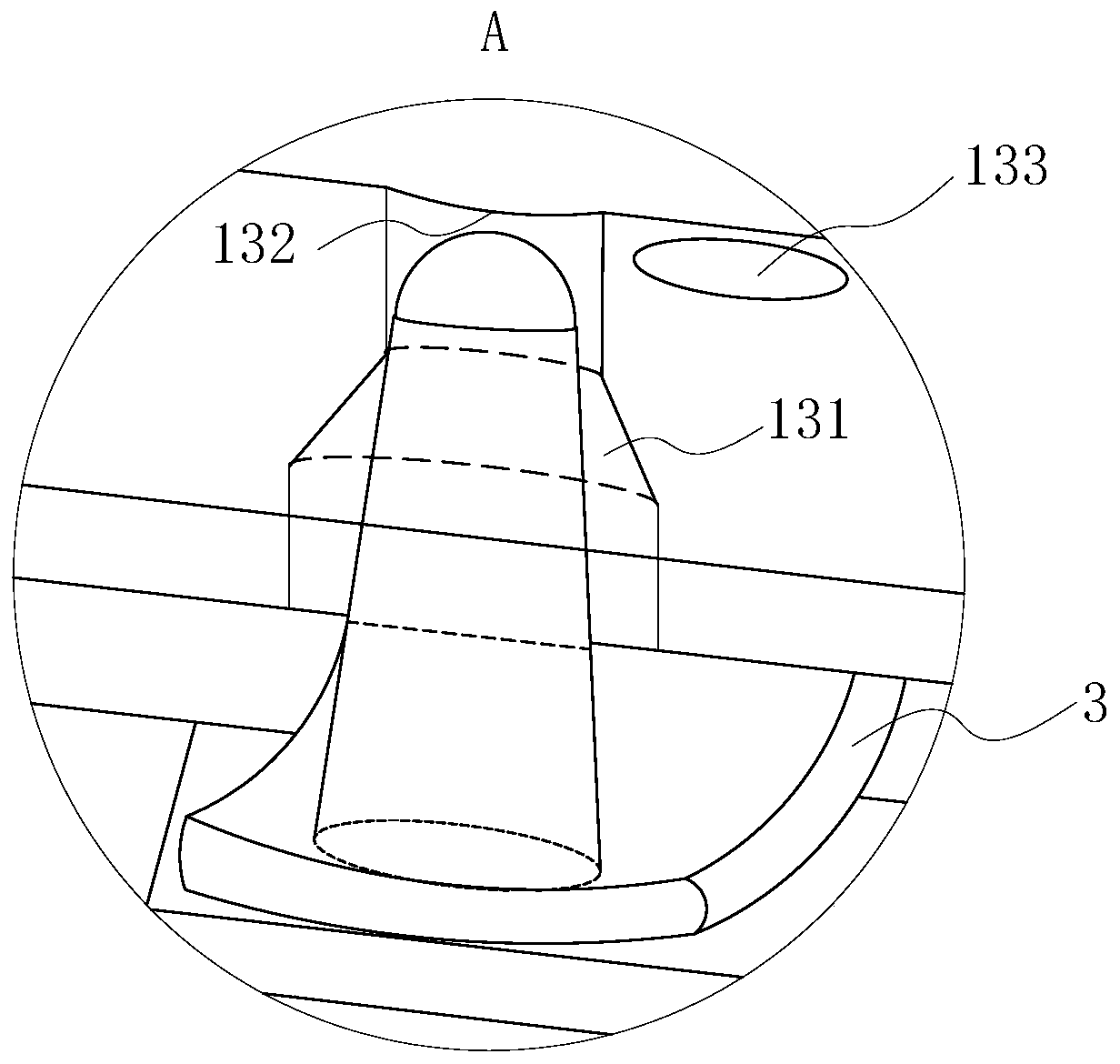

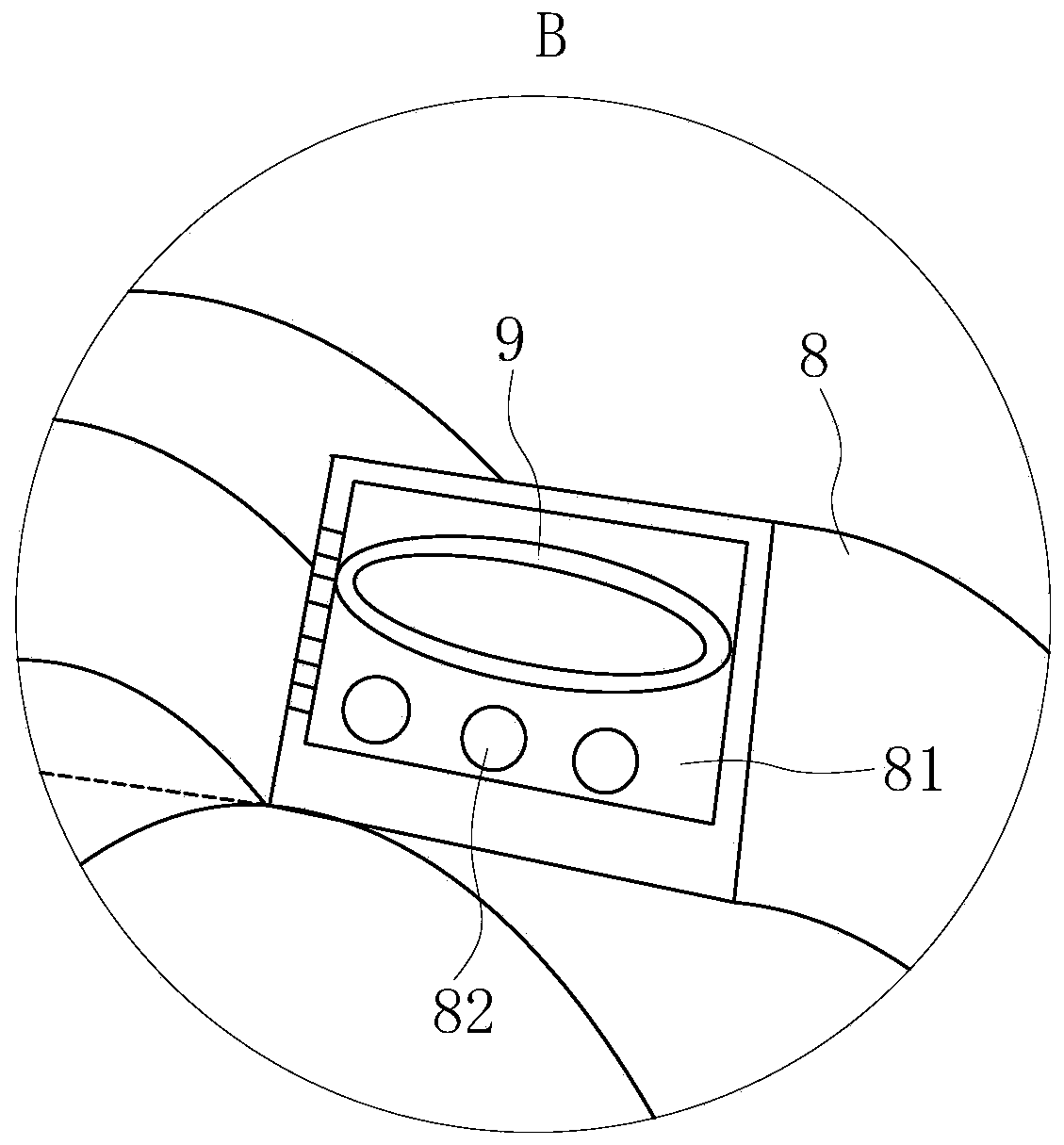

[0021] use Figure 1-Figure 5 A rubber roller according to one embodiment of the present invention will be described below.

[0022] Such as Figure 1-Figure 5As shown, a rubber roller according to the present invention includes a rotating main roller 1, a rubber base layer 11 and a glass fiber layer 12; the outer wall of the rotating main roller 1 is provided with a rubber base layer 11, and the outer wall of the rubber base layer 11 A glass fiber layer 12 is arranged on it; an insulating cavity 121 is opened inside the glass fiber layer 12, and an elastic wear-resistant layer 13 is arranged on the outer wall of the glass fiber layer 12; an elastic metal mesh 2 is arranged in the insulating cavity 121; The elastic wear-resistant layer 13 is uniformly provided with stepped holes 131, and the diameters of the stepped holes 131 increase sequentially from top to bottom; It communicates with the insulating cavity 121; the bottom of the insulating cavity 121 is provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com