A solid solution formed of tungsten bronze and perovskite structure oxide and its preparation method

A technology of perovskite structure and solid solution, applied in the field of solid solution, can solve the problem of no solid solution of heterogeneous materials, and achieve the effects of excellent room temperature energy storage properties, changing microscopic morphology, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

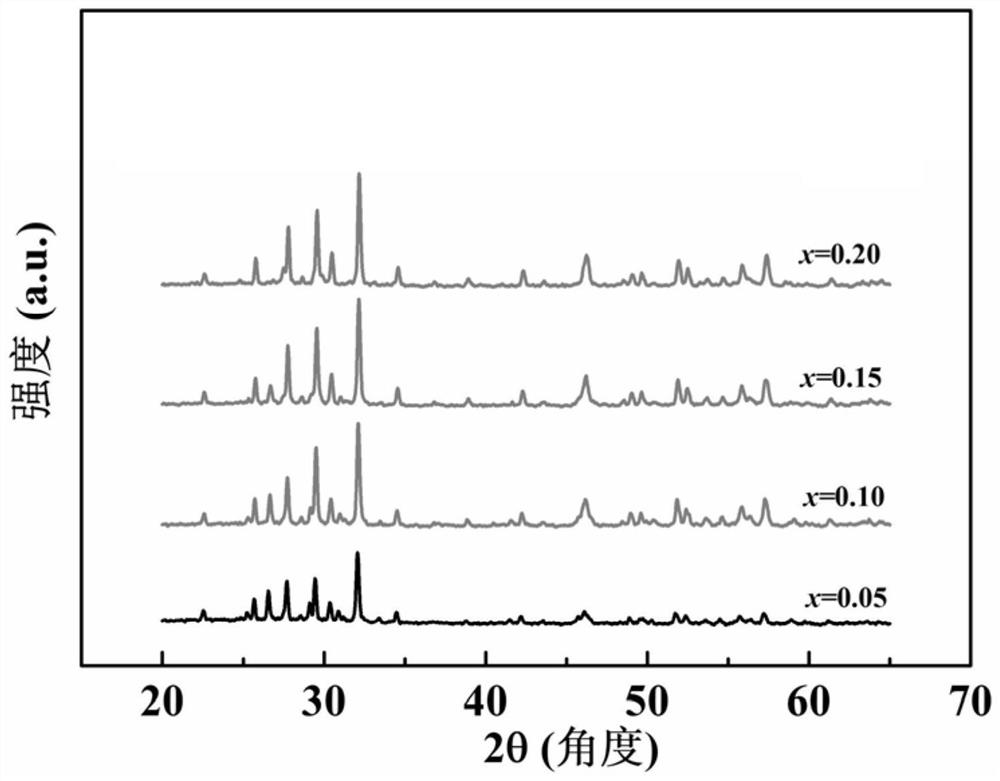

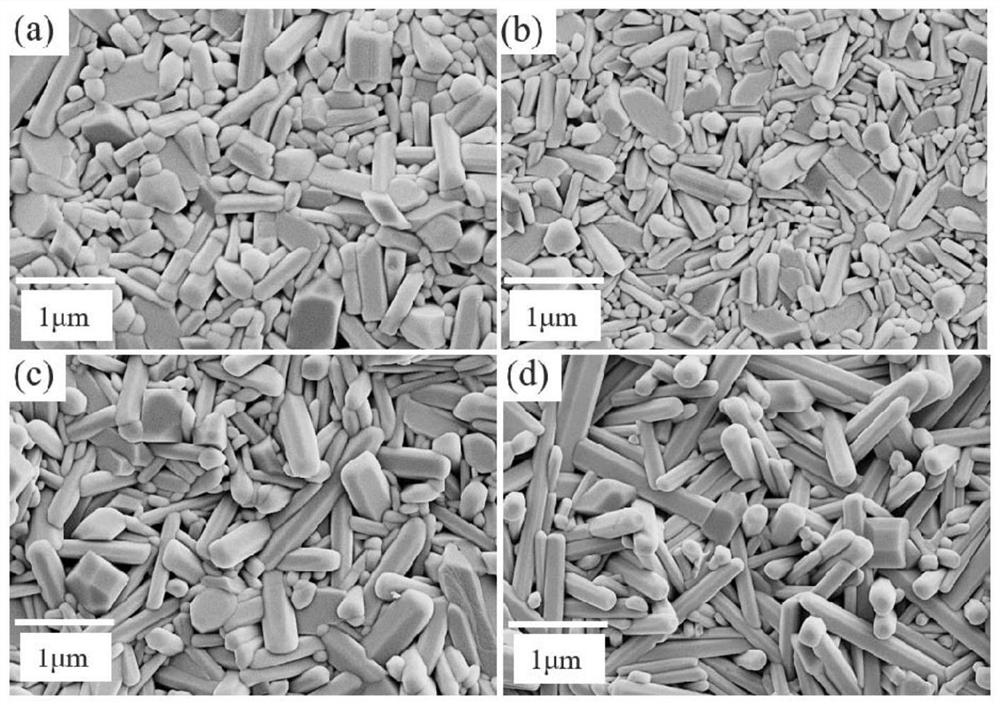

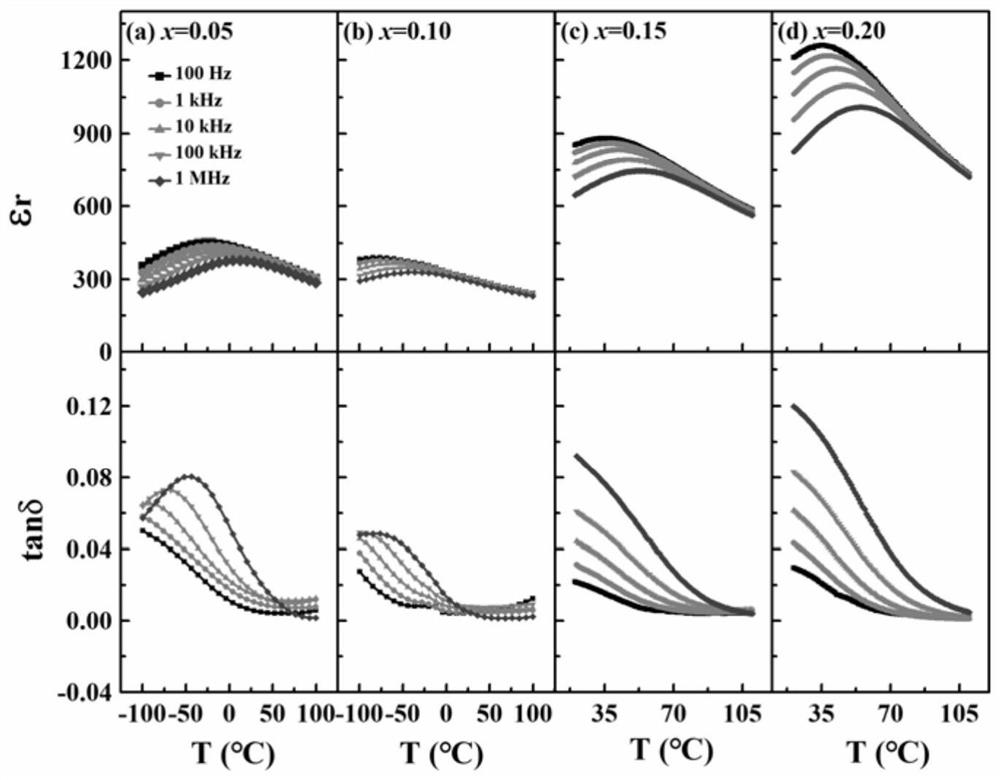

Embodiment 1

[0021] Weigh 5.8287 grams of SBN powder and 0.1713 grams of BNBT (x=0.05) powder, add an appropriate amount of alcohol to the mixture of the two powders, and then ball mill for 24 hours to mix the two powders evenly. After the obtained powder is dried, an appropriate amount of powder is pressed into a sheet with a diameter of about 10 mm and a thickness of about 2-3 mm with a pressure of 15 MPa. Put appropriate amount of corresponding powder into Al 2 o 3 Crucible, then put the slice into it, and cover the slice with the corresponding powder, and finally use another crucible to buckle upside down on the first crucible, so that the slice is in a sealed state. Put the crucible sealed with the flakes into a muffle furnace and raise the temperature, and the heating rate from room temperature to the sintering temperature (1200° C.) is controlled at 3° C. / min. After sintering at 1300 °C for 3 h, the temperature was lowered to 600 °C at a cooling rate of 3 °C / min, and then cooled n...

Embodiment 2

[0023] Weigh 5.6496 g of SBN powder and 0.3504 g of BNBT (x=0.10) powder, add an appropriate amount of alcohol to the mixture of the two powders, and then ball mill for 24 hours to mix the two powders evenly. After the obtained powder is dried, an appropriate amount of powder is pressed into a sheet with a diameter of about 10 mm and a thickness of about 2-3 mm with a pressure of 15 MPa. Put appropriate amount of corresponding powder into Al 2 o 3 Crucible, then put the slice into it, and cover the slice with the corresponding powder, and finally use another crucible to buckle upside down on the first crucible, so that the slice is in a sealed state. Put the crucible sealed with the flakes into a muffle furnace and raise the temperature, and the heating rate from room temperature to the sintering temperature (1250° C.) is controlled at 3° C. / min. After sintering at 1220°C for 3h, the temperature was lowered to 600°C at a rate of 3°C / min, and then cooled naturally. (1-x)SBN-...

Embodiment 3

[0025] Weigh 5.4620 g of SBN powder and 0.5380 g of BNBT (x=0.15) powder, add an appropriate amount of alcohol to the mixture of the two powders, and then ball mill for 24 hours to mix the two powders evenly. After the obtained powder is dried, an appropriate amount of powder is pressed into a sheet with a diameter of about 10 mm and a thickness of about 2-3 mm with a pressure of 15 MPa. Put appropriate amount of corresponding powder into Al 2 o 3 Crucible, then put the slice into it, and cover the slice with the corresponding powder, and finally use another crucible to buckle upside down on the first crucible, so that the slice is in a sealed state. Put the crucible sealed with the flakes into a muffle furnace and raise the temperature, and the heating rate from room temperature to the sintering temperature (1200° C.) is controlled at 3° C. / min. After sintering at 1200°C for 3h, the temperature was lowered to 600°C at a cooling rate of 3°C / min, and then cooled naturally. (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com