An air mattress outer belt material, an inner pull belt material, its preparation method and an air mattress

A technique for an air mattress and a peripheral belt, applied to the material of the inner pull belt, the material of the outer belt of the air mattress, its preparation method and the field of the air mattress, which can solve the problems of unfamiliar welding, easy deformation, and air leakage at the weld And other problems, to achieve the effect of good mechanical properties, good flexibility, not easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides an air mattress, including a peripheral belt and an inner pull belt welded to each other;

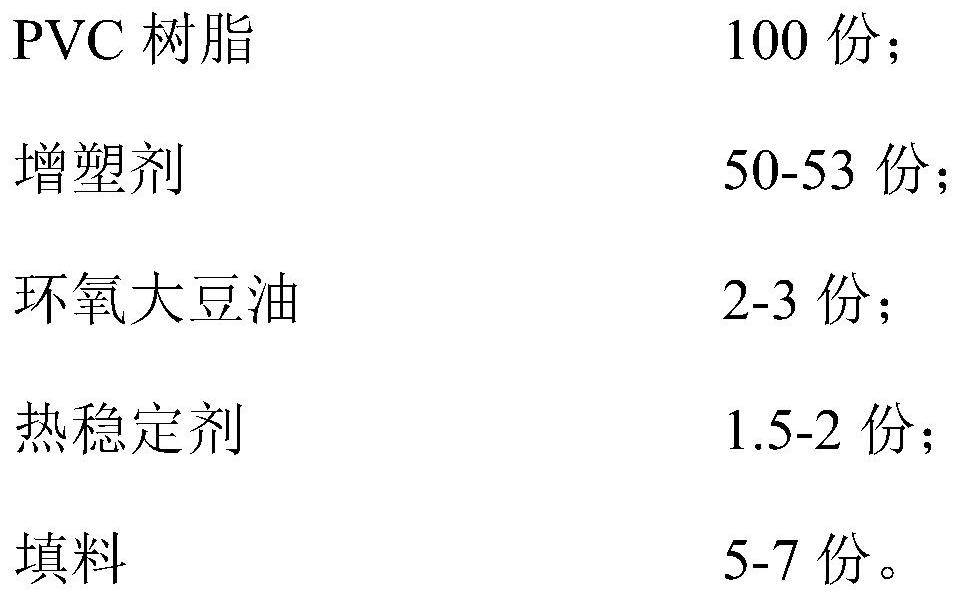

[0067] Wherein, the peripheral belt material includes the following components in parts by weight:

[0068]

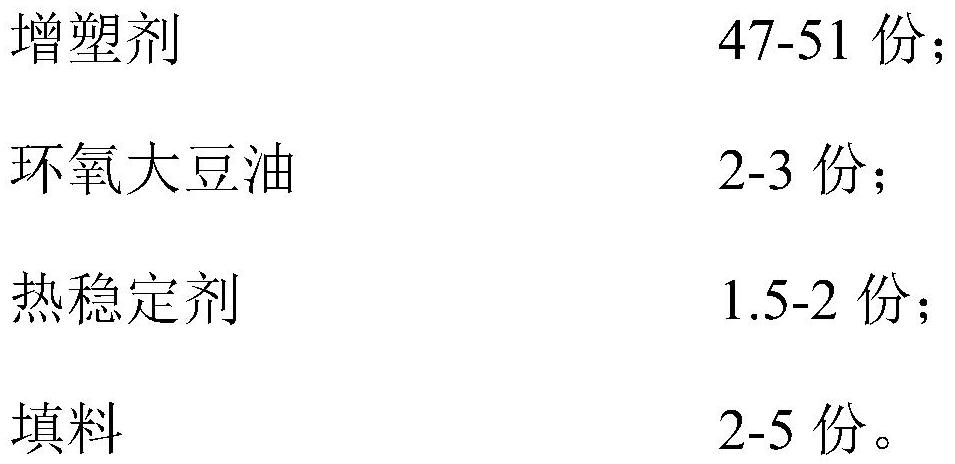

[0069] The inner drawstring material comprises the following components in parts by weight:

[0070]

[0071] The types of components in the outer belt material and the inner belt material are as follows:

[0072] PVC resin is K-70PVC resin (number-average molecular weight is about 75,000), and plasticizer is DINP; The epoxy value 0.06 of epoxy soybean oil, the iodine value 2.8g I 2 / 100g, the acid value is 0.45mg KOH / g; the heat stabilizer is a barium-zinc composite liquid stabilizer, the precipitation da value of the machine surface is ≤0.8, the barium content is less than 75000ppm, and the phenol content is less than 2500ppm; the filler is ground calcium carbonate, The number is 800 mesh.

[0073] Both the peripheral belt material and ...

Embodiment 2

[0077] This embodiment provides an air mattress, including a peripheral belt and an inner pull belt welded to each other;

[0078] Wherein, the peripheral belt material includes the following components in parts by weight:

[0079]

[0080] The inner drawstring material comprises the following components in parts by weight:

[0081]

[0082] The types of components in the outer belt material and the inner belt material are as follows:

[0083] PVC resin is K-68.5PVC resin (number-average molecular weight is about 71,000), and plasticizer is DOTP; The epoxy value 0.06 of epoxy soybean oil, the iodine value 2.8g I 2 / 100g, the acid value is 0.45mg KOH / g; the heat stabilizer is a barium-zinc composite liquid stabilizer, the precipitation da value of the machine surface is ≤0.8, the barium content is less than 75000ppm, and the phenol content is less than 2500ppm; the filler is ground calcium carbonate, The number is 1200 mesh.

[0084] Both the peripheral belt material a...

Embodiment 3

[0088] This embodiment provides an air mattress, including a peripheral belt and an inner pull belt welded to each other;

[0089] Wherein, the peripheral belt material includes the following components in parts by weight:

[0090]

[0091] The inner drawstring material comprises the following components in parts by weight:

[0092]

[0093] The types of components in the outer belt material and the inner belt material are as follows:

[0094] PVC resin is K-71.5PVC resin (number-average molecular weight is about 79,800), and plasticizer is DINP; The epoxy value of epoxy soybean oil is 0.06, and the iodine value is 2.8g I 2 / 100g, the acid value is 0.45mg KOH / g; the heat stabilizer is a barium-zinc composite liquid stabilizer, the precipitation da value of the machine surface is ≤0.8, the barium content is less than 75000ppm, and the phenol content is less than 2500ppm; the filler is ground calcium carbonate, The number is 1500 mesh.

[0095] Both the peripheral belt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com