Lanthanum sorbate composite heat stabilizer for pvc

A composite heat stabilizer, lanthanum sorbate technology, applied in the field of heat stabilizers for PVC, can solve the problems of strong odor, easy vulcanization pollution, high price, etc., and achieve excellent static thermal stability and dynamic thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

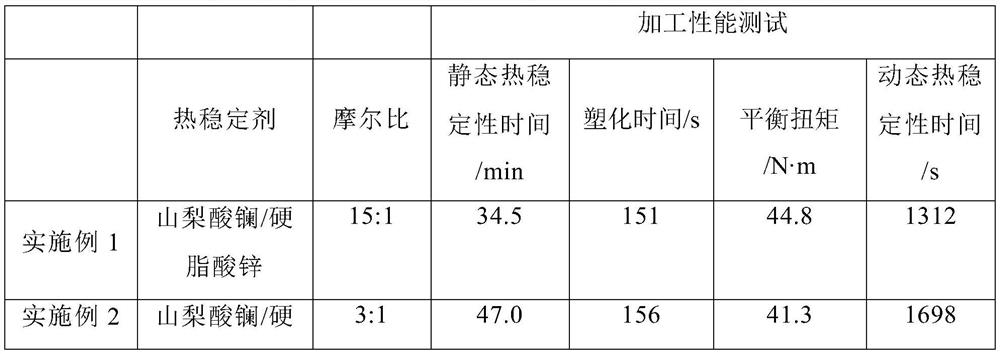

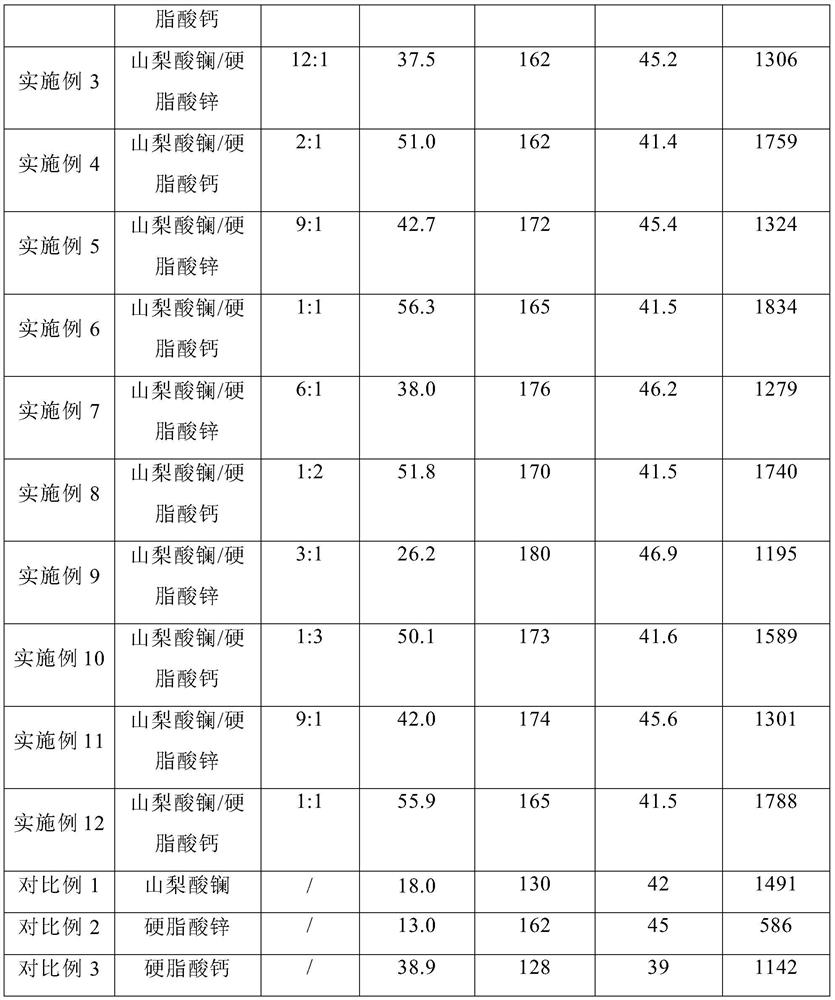

Examples

Embodiment 1

[0020] Preparation of lanthanum sorbate: add water into a three-necked flask as a solvent; add 0.03mol sorbic acid into the solvent; heat up to 70°C, keep warm for a period of time until the sorbic acid is fully dissolved, take 0.03mol sodium hydroxide and mix it with deionized water into a 0.5 mol / L solution, transferred to a constant pressure dropping funnel, dropped into a three-necked flask, and controlled at a rate of 1 drop / s, until the pH of the solution = 7, and kept stirring during the dropping process. Prepare 0.01mol lanthanum nitrate with deionized water to make a 0.1mol / L solution, slowly drop it into a flask, control the reaction temperature at 80°C, keep the reaction for 40min, and then filter with suction to obtain a precipitate. Wash the precipitate with absolute ethanol at 60-70°C for 2-3 times, and dry it in a blast drying oven at 70°C to obtain lanthanum sorbate.

[0021] The preparation of zinc stearate: adopt above-mentioned same method, make zinc stearat...

Embodiment 2

[0024] Preparation of lanthanum sorbate: add water into a three-necked flask as a solvent; add 0.03mol sorbic acid into the solvent; heat up to 70°C, keep warm for a period of time until the sorbic acid is fully dissolved, take 0.03mol sodium hydroxide and mix it with deionized water into a 0.5 mol / L solution, transferred to a constant pressure dropping funnel, dropped into a three-necked flask, and controlled at a rate of 1 drop / s, until the pH of the solution = 7, and kept stirring during the dropping process. Prepare 0.01mol lanthanum nitrate with deionized water to make a 0.1mol / L solution, slowly drop it into a flask, control the reaction temperature at 80°C, keep the reaction for 40min, and then filter with suction to obtain a precipitate. Wash the precipitate with absolute ethanol at 60-70°C for 2-3 times, and dry it in a blast drying oven at 70°C to obtain lanthanum sorbate.

[0025] Preparation of calcium stearate: adopt above-mentioned same method, make calcium stear...

Embodiment 3

[0028] Preparation of lanthanum sorbate: Add water into a three-necked flask as a solvent; add 0.03mol sorbic acid into the solvent; heat up to 80°C, keep warm for a period of time until the sorbic acid is fully dissolved, and take 0.03mol sodium hydroxide and mix it with deionized water into a 1 mol / L solution, transferred to a constant pressure dropping funnel, and dropped into a three-necked flask at a controlled rate of 1 drop / s until the pH of the solution was 7, with constant stirring during the dropping process. Prepare 0.01mol lanthanum nitrate with deionized water to make 0.3mol / L solution, slowly drop it into the flask, control the reaction temperature at 80°C, keep the reaction for 40min, and then suction filter to obtain the precipitate. Wash the precipitate with absolute ethanol at 60-70°C for 2-3 times, and dry it in a blast drying oven at 70°C to obtain lanthanum sorbate.

[0029] The preparation of zinc stearate: adopt above-mentioned same method, make zinc ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com