Lead-free and low-toxicity polyvinyl chloride composite material and preparation method thereof

A technology of polyvinyl chloride and composite materials, applied in the field of lead-free and low-toxicity polyvinyl chloride composite materials and their preparation, can solve the problems of deposition, producer injury, hidden dangers of human and animal health, etc., achieve strong weather resistance, reduce dust , the effect of excellent static thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

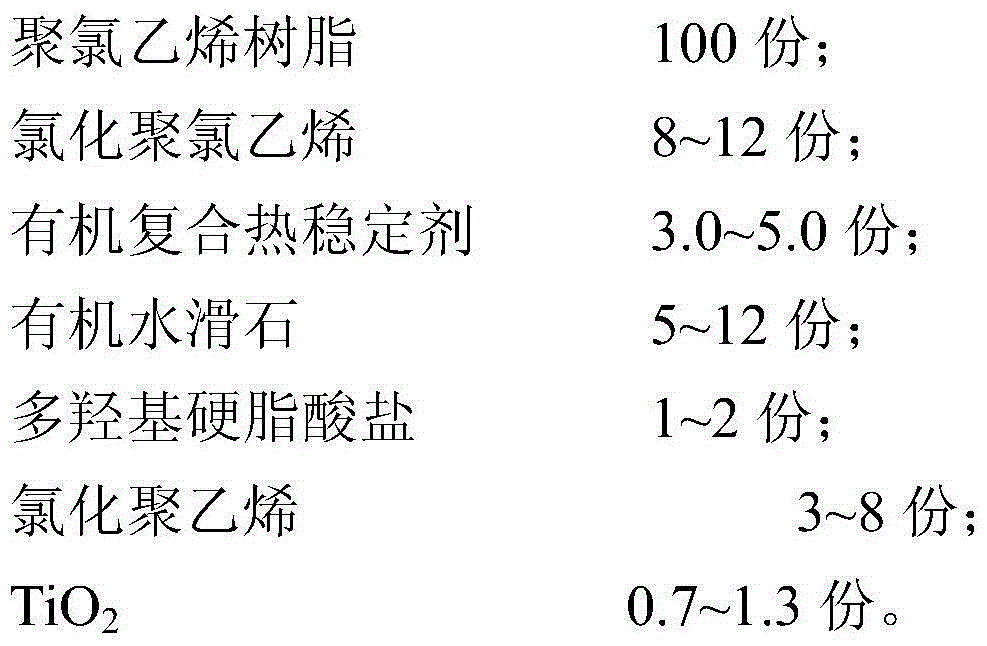

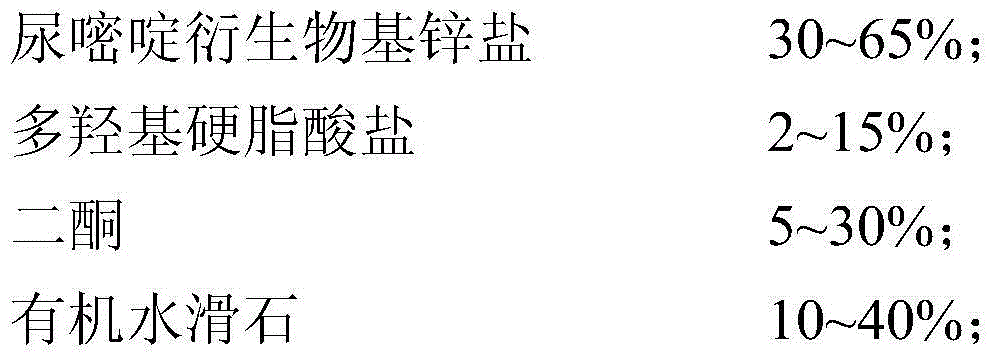

Method used

Image

Examples

Embodiment 1

[0059] Add 0.1mol sodium metal to 100ml absolute ethanol, stir and reflux for 0.5h to prepare a concentrated sodium ethylate / ethanol solution; 0.1mol urea, 0.2mol cyanoacetic acid, and 0.1mol acetic anhydride are reacted and refluxed for 40min at 80°C in a 500ml three-necked flask Finally, add 100ml of the prepared concentrated sodium ethylate / ethanol solution and continue to heat and reflux for 3h, then slowly add hydrochloric acid solution dropwise to adjust the pH to 7, then add 0.1mol of stearic acid until it completely melts and dissolves; after raising the temperature to 95°C, Slowly add 0.1mol of zinc chloride dropwise, and then stir for 2.5h after dropping, after cooling to room temperature, filter the product with suction, soak and wash with water mist, dry at 80-90°C to constant weight, and prepare N,N-di Methyl-6-aminouracil zinc salt, yield 83%.

[0060] Convert the anion to CO 3 2- 0.95 kg of hydrotalcite, 0.05 kg of bisphenol A epoxy resin (E44) with an epoxy v...

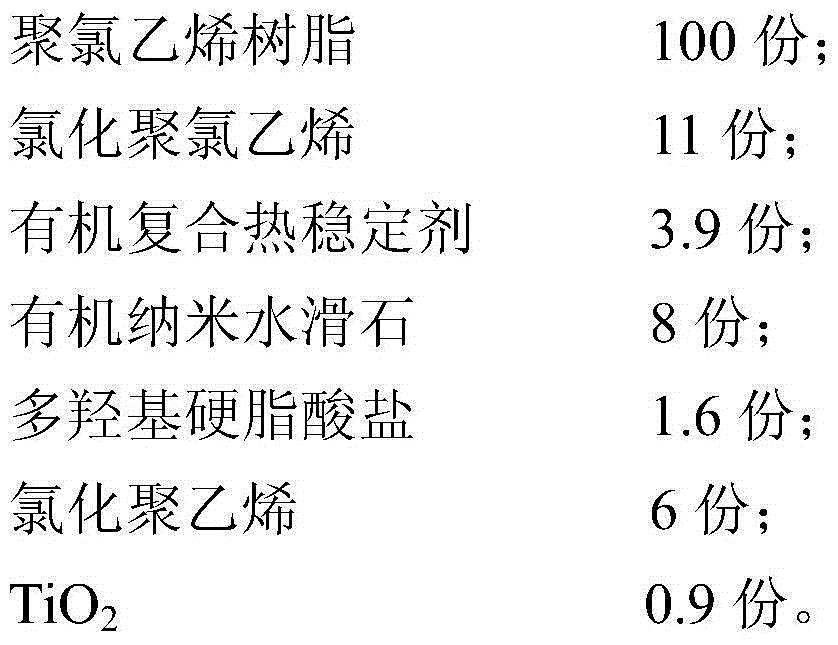

Embodiment 2

[0063] Add 0.1mol sodium metal to 100ml absolute ethanol, stir and reflux for 0.5h to obtain a concentrated sodium ethylate / ethanol solution; add 0.1mol urea and continue to reflux for 0.5h, then add 10.6ml of ethyl cyanoacetate dropwise and continue to reflux for 3h before cooling Slowly add hydrochloric acid solution dropwise to adjust the pH to 7, then add 0.1mol of stearic acid until it is completely melted and dissolved; after raising the temperature to 90-95°C, slowly add 0.1mol of zinc chloride dropwise, and then stir for 2.5h after the dropwise completion. After cooling to room temperature, the product was suction-filtered, soaked and washed with water mist, and dried at 80-90° C. to constant weight to prepare N-methyl-6-aminouracil zinc salt with a yield of 93%.

[0064] Convert the anion to CO 3 2- 0.95 kg of hydrotalcite, 0.05 kg of bisphenol A epoxy resin (E44) with an epoxy value of 0.4 to 0.6, pre-mixed evenly, and sheared and mixed for 20 minutes on a mixer at ...

Embodiment 3

[0068] Add 0.1mol sodium metal to 100ml absolute ethanol, stir and reflux for 0.5h to obtain a concentrated sodium ethylate / ethanol solution, then add 0.1mol thiourea and continue to reflux for 0.5h, then add 10.6ml of ethyl cyanoacetate dropwise and continue to reflux for 3h . After cooling, add 4mol / L hydrochloric acid solution dropwise to adjust the pH to 7, then add 0.1mol stearic acid until it completely melts and dissolves; after raising the temperature to 90-95°C, slowly add 0.1mol zinc sulfate heptahydrate dropwise. Stir for another 2.5h, after cooling to room temperature, filter the product with suction, soak and wash with water mist, and dry at 80-90°C to constant weight to prepare N-methyl-6-thiosemicarbazide zinc salt with a yield of 95% .

[0069] Convert the anion to CO 3 2- 0.95 kg of hydrotalcite, 0.05 kg of bisphenol A epoxy resin (E44) with an epoxy value of 0.4 to 0.6, after pre-mixing uniformly, shear and knead for 20 minutes on a mixer at 140 ° C to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com