Dihydropyridine PVC composite heat stabilizer and preparation method thereof

A composite heat stabilizer and dihydropyridine technology, which is applied in the field of dihydropyridine PVC composite heat stabilizer and its preparation, can solve problems such as instability in the later stage of processing, and achieve improved thermal stability time, excellent initial whiteness, and plasticity. The effect of enhanced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0029] Preparation of Molecular Sieve Modified by Sodium Perchlorate

[0030] The 4A type molecular sieve is subjected to water removal treatment in an industrial microwave oven, mixed with perchlorate after being taken out, cooled to room temperature and fully ground to obtain a modified molecular sieve. The drying temperature is 375±25°C, the drying time is 3 hours, and the mixing time is 20 minutes.

[0031] The mass ratio of perchlorate to dried 4A molecular sieve is 2:3.

[0032] Preparation of dihydropyridine PVC composite heat stabilizer:

[0033] Dihydropyridine can be prepared by co-heating (1 hour) ethyl acetoacetate and urotropine in ethanol solution of ammonium acetate; the obtained liquid is cooled to precipitate crystals, filtered and washed with ethanol, and dried in air to obtain a light yellow powder like dihydropyridine.

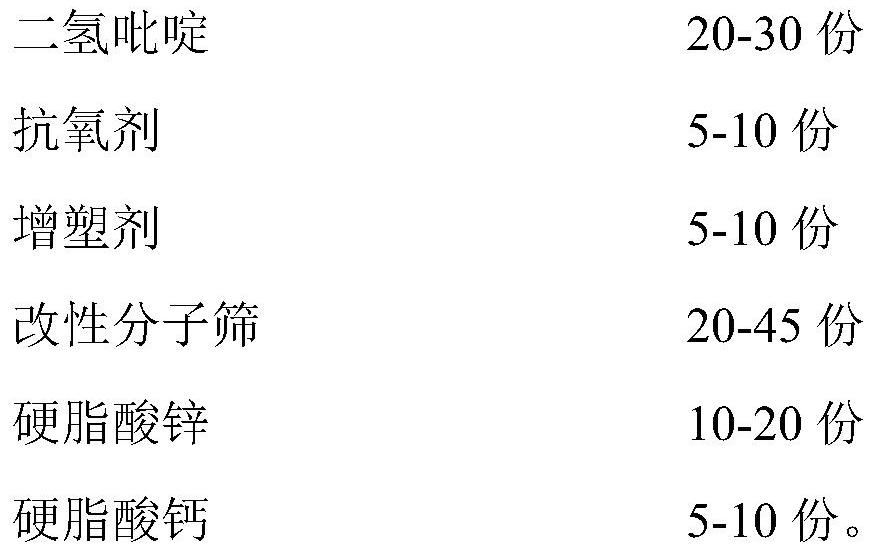

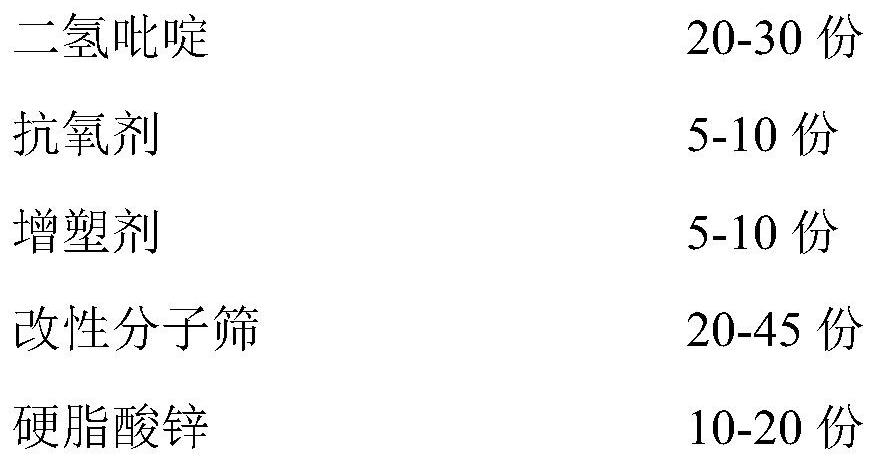

[0034] In a high-speed mixer, add dihydropyridine and heat up to 80-90°C, continue to add sodium perchlorate modified molecular sieves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com