Dam concrete steel formwork structure and construction and installation method thereof

An installation method and technology of steel formwork, which are applied in basic structure engineering, water conservancy engineering, marine engineering and other directions, can solve the problems of inconvenient operation of the formwork, insufficient structural rigidity, cumbersome operation, etc., and achieve simple structure, simple construction and installation, and reduce the temperature difference between inside and outside. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

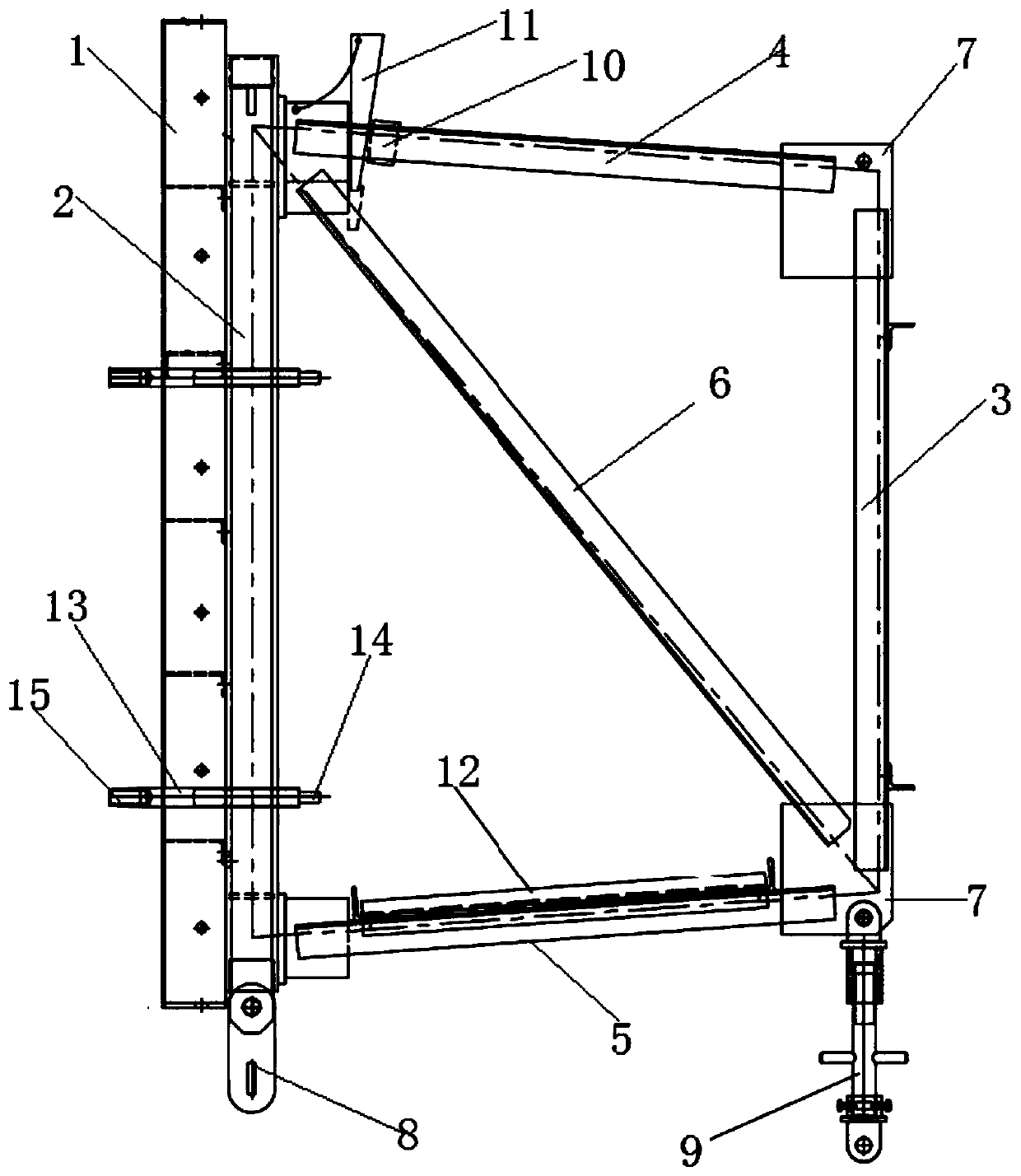

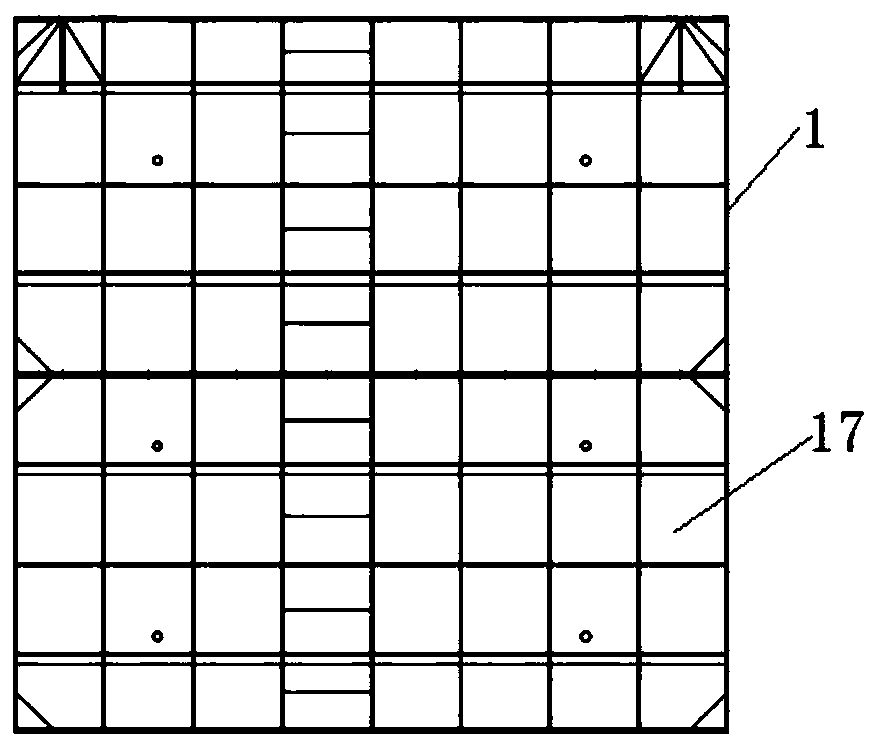

[0035] Such as figure 1 with 2 As shown, a dam concrete steel formwork structure, the steel formwork structure includes a panel 1 and a truss assembly on one side of the panel,

[0036] The truss assembly includes a first vertical support 2 and a second vertical support 3, at least two horizontal supports are arranged between the first vertical support 2 and the second vertical support 3, and the horizontal supports The ends of the first vertical support 2 and the second vertical support 3 are respectively screwed together through the mounting plate 7 to form a quadrilateral structure, and the opposite corners of the quadrilateral structure are also provided with inclined supports 6; the first The vertical support 2 is arranged close to the panel 1, and a foot 8 is provided under the first vertical support 2; an adjustment rod 9 is provided under the second vertical support 3, and the adjustment rod 9 is screwed On the mounting plate 7; a working platform 12 is provided on t...

Embodiment 2

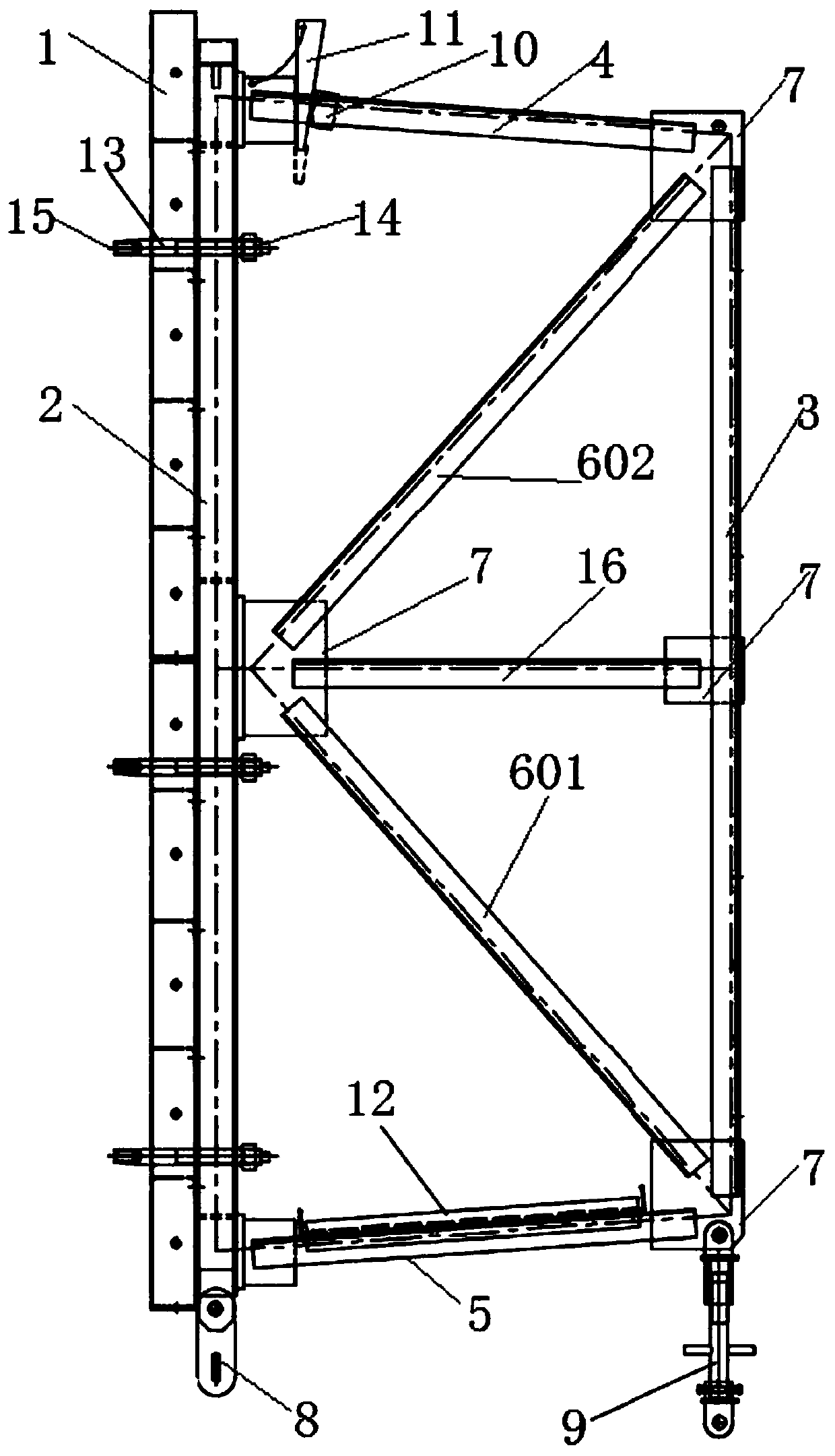

[0045] Such as image 3 As shown, a dam concrete steel formwork structure, the steel formwork structure includes a panel 1 and a truss assembly on one side of the panel, the longitudinal section of the panel is rectangular, 3 meters long and 3 meters high;

[0046] The truss assembly includes a first vertical support 2 and a second vertical support 3, an upper horizontal support 4, a lower horizontal support 5 and The middle horizontal support 16, the upper, middle and lower horizontal supports and the ends of the first vertical support 2 and the second vertical support 3 are respectively screwed together through the mounting plate 7 to form two quadrilateral structures. A first inclined support 602 is provided between the support 4 and the middle transverse support 16, and a second inclined support 601 is provided between the lower transverse support 5 and the middle transverse support 16; the first inclined support 602 and One end of the second inclined support 601 close to...

Embodiment 3

[0052] A construction and installation method of a dam concrete steel formwork structure, the construction and installation method comprises the following steps:

[0053] Step 1: Divide the dam into upper and lower multi-layer construction areas according to the construction drawings, divide and number the construction areas of each layer according to the construction drawings, and lay the steel formwork structure from the bottom construction area;

[0054] Step 2: Check the flatness of the bottom plate in the construction area, apply a mortar leveling layer, and pre-embed the tension module in it, and the tension module is connected with tension bars;

[0055] Step 3: During the process of step 2, prepare the steel formwork, assemble the steel formwork structures in batches in advance, clean them up, and label them for later use;

[0056] Step 4: Install the steel formwork structure in the construction area, install it in the order of horizontal first and then vertical or fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com