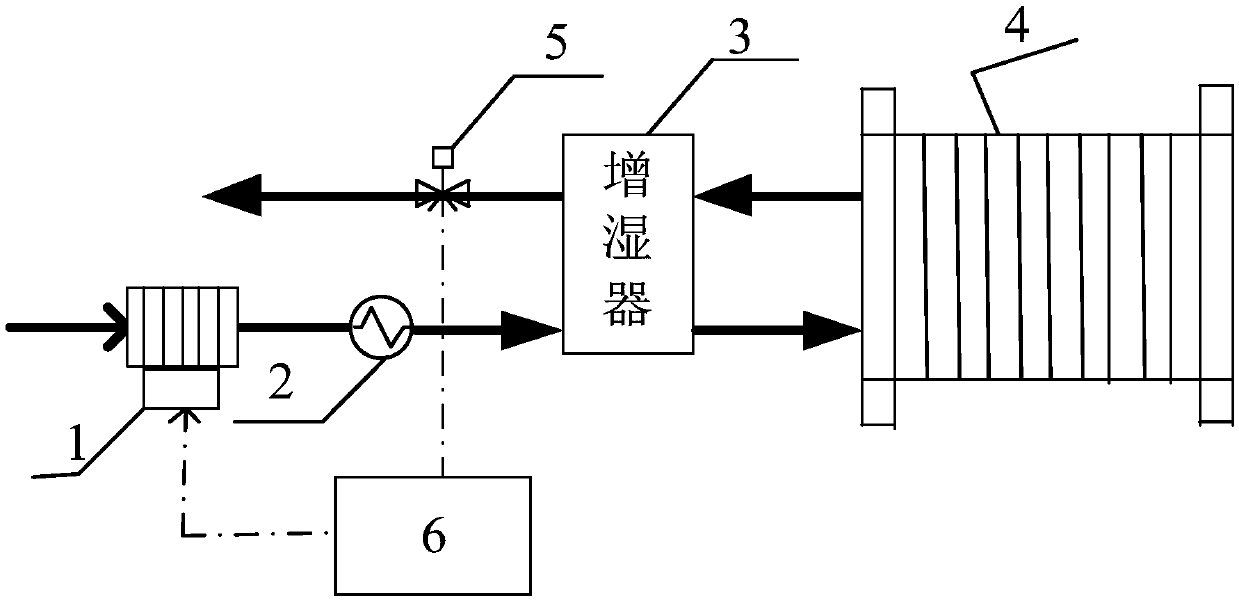

Fuel cell system and control method thereof

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, reactant parameter control, etc., can solve problems such as air compressor surge, improper handling of system target pressure changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

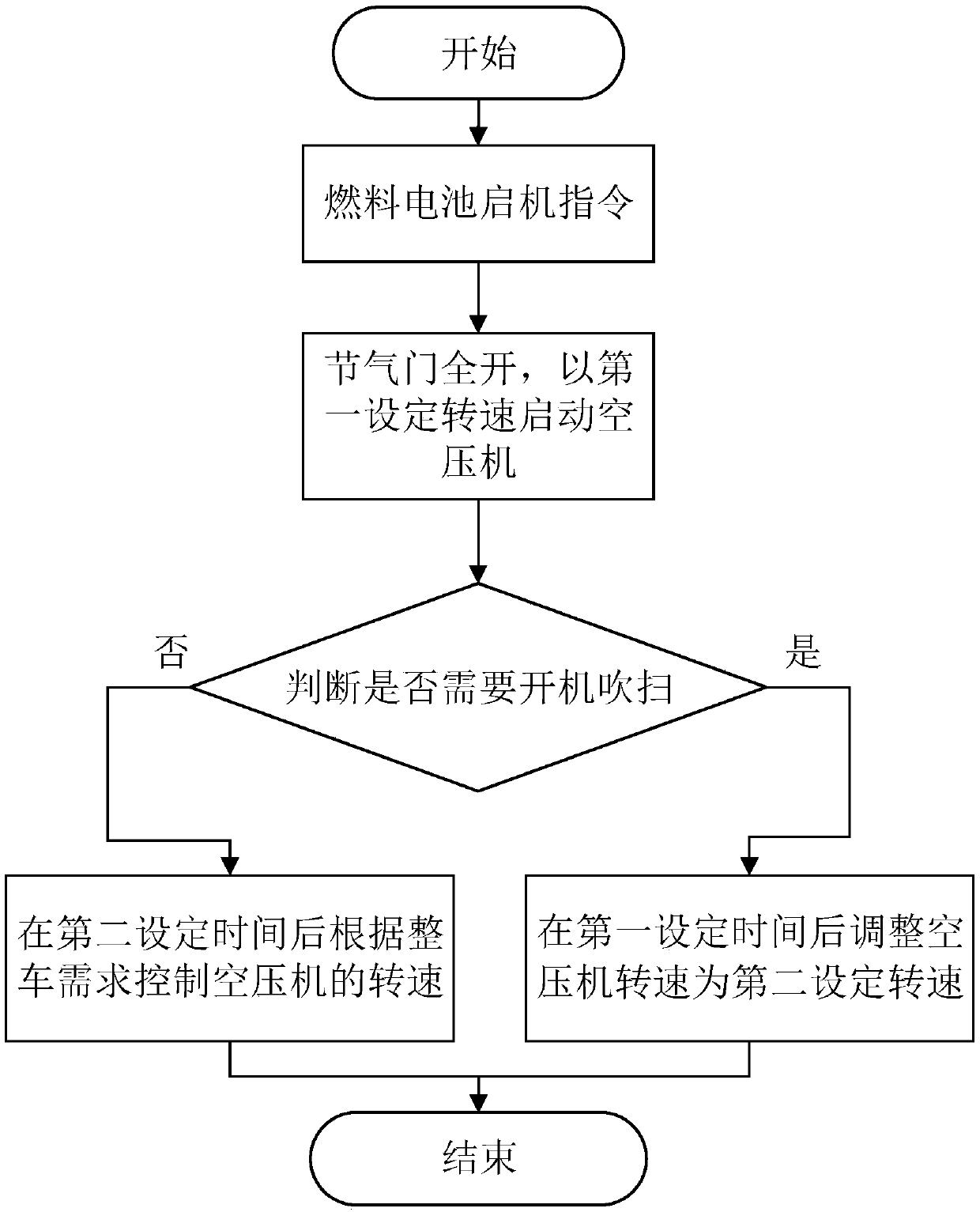

Embodiment 1

[0066] Embodiment 1 provides a fuel cell system start-up control method, such as figure 2 As shown, it is the control mode of the air compressor in the process of switching from start-up to normal operation of the fuel cell system, including the following steps:

[0067] S101. When the fuel cell is turned on, the controller controls the throttle valve to fully open and starts the air compressor at the first set speed.

[0068] The fuel cell controller controls the full opening of the throttle valve and at the same time controls the start of the air compressor, and preferably the first set speed is 0 rpm.

[0069] S102. When the controller judges that it is necessary to power on and purge, adjust the speed of the air compressor to the second set speed after the first set time.

[0070] According to the conditions, judge whether it is necessary to purge the liquid water accumulated in the cathode flow channel. When it is necessary to purge, adjust the speed to the second set s...

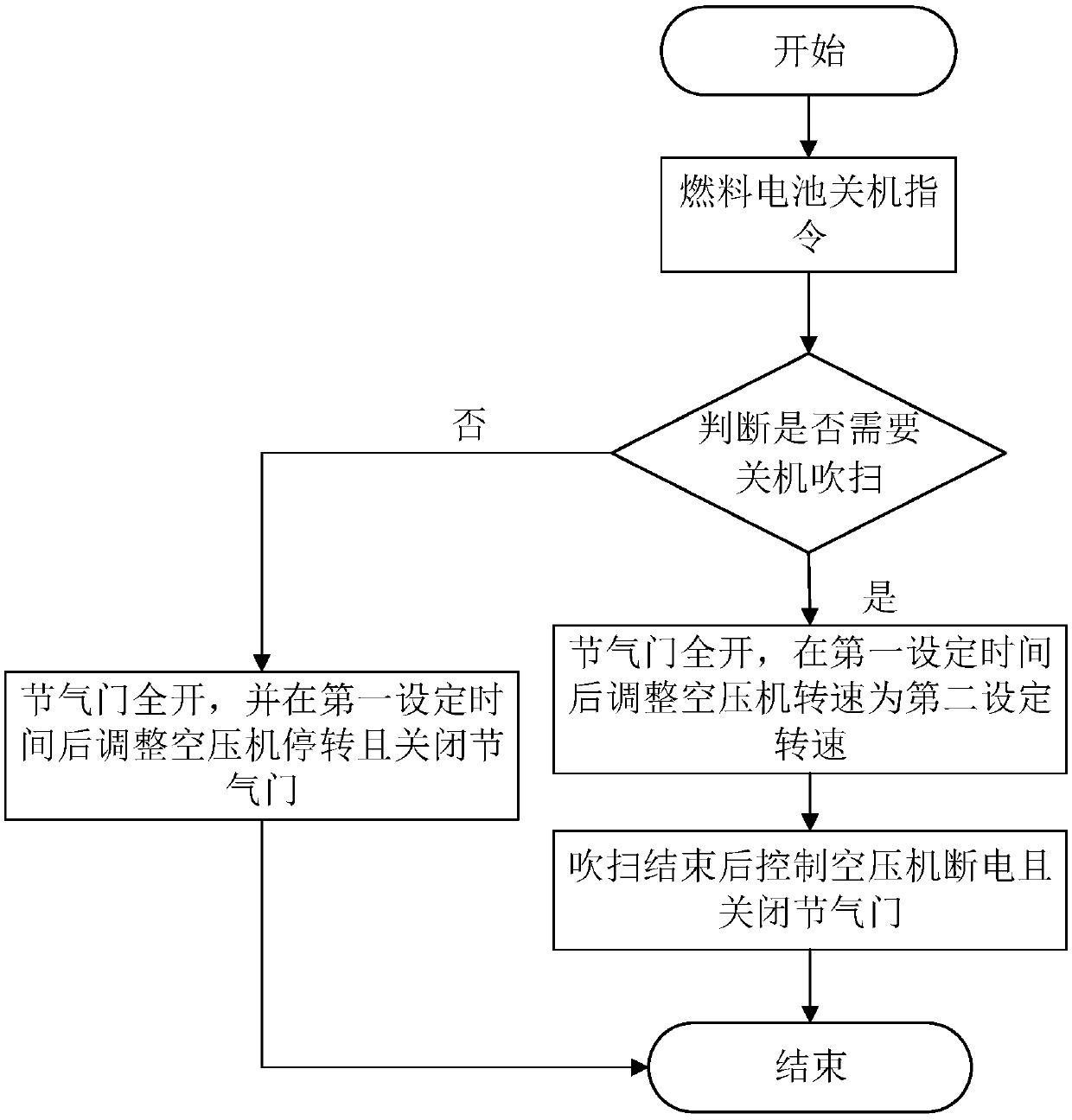

Embodiment 2

[0075] In order to prevent the phenomenon of air compressor surge between normal operation and shutdown of the fuel cell system, this embodiment 2 provides a fuel cell system shutdown control method, such as image 3 As shown, the control mode of the air compressor and the throttle valve during the shutdown process of the fuel cell system includes the following steps:

[0076] S201. Determine whether to shut down and purge.

[0077] According to the conditions, it is judged whether it is necessary to purge the liquid water accumulated in the cathode channel, and if so, the throttle valve is fully opened, and the speed of the air compressor is adjusted to the first set speed value after the first set time. Preferably, the first set time is 1s, and the first set rotational speed is the rated rotational speed, so as to achieve the best purging effect.

[0078] S202. If not, control the throttle valve to fully open, and adjust the air compressor to stop and close the throttle val...

Embodiment 3

[0083] On the basis of embodiment 1 or embodiment 2, this embodiment 3 provides a control method for a fuel cell system during normal operation, such as Figure 4 Shown is the control method of the air compressor in the normal operation of the fuel cell system, including the following steps:

[0084] S301, judging whether purging is required according to the amount of liquid water in the cathode channel.

[0085] There are many ways to judge the amount of liquid water in the cathode flow channel. It can be judged whether purge is needed by judging whether the voltage of the fuel cell single chip is lower than the set voltage threshold. At this time, the fuel cell controller is connected to the corresponding fuel cell single chip through the input terminal. The voltage signal output terminal is used to obtain the single-chip voltage of the fuel cell.

[0086] S302. Perform purging if necessary.

[0087] During the operation of the fuel cell, if the voltage of the fuel cell is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com