Anti-mildew granary and anti-mildew control method in grain storage process

An anti-mildew and storage technology, applied in the field of grain storage, can solve the problems of inability to dry the inner wall of the granary and the internal environment of the granary, and achieve the effect of preventing incomplete drying and preventing grain from becoming moldy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

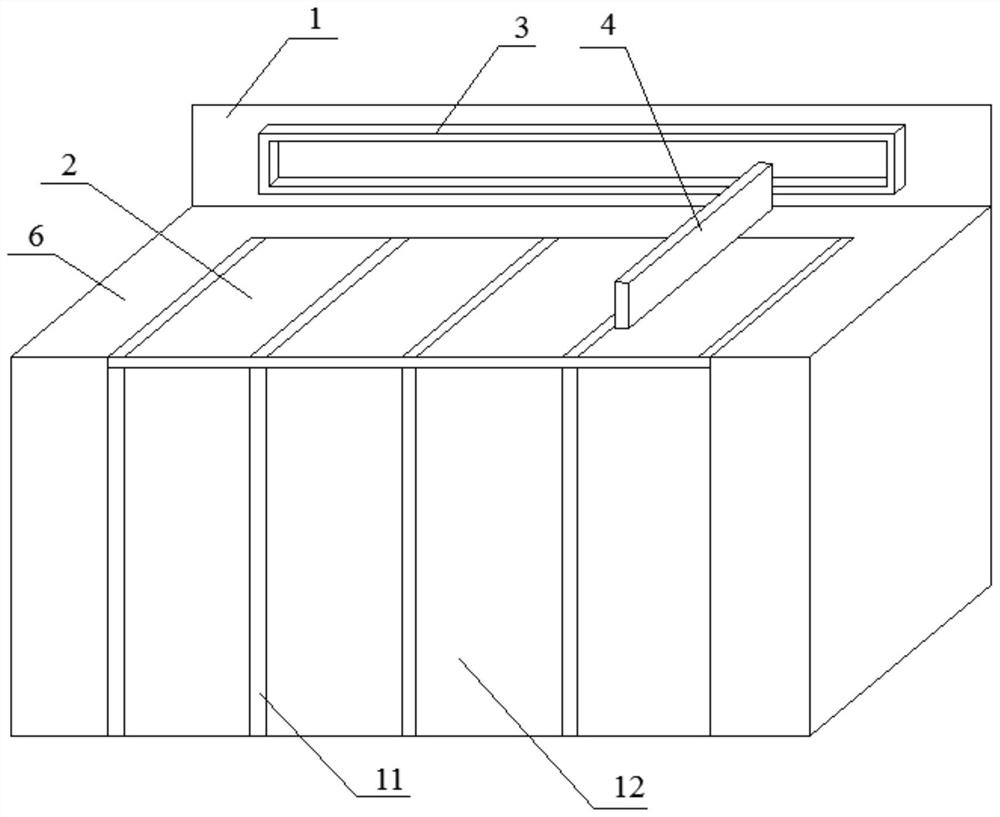

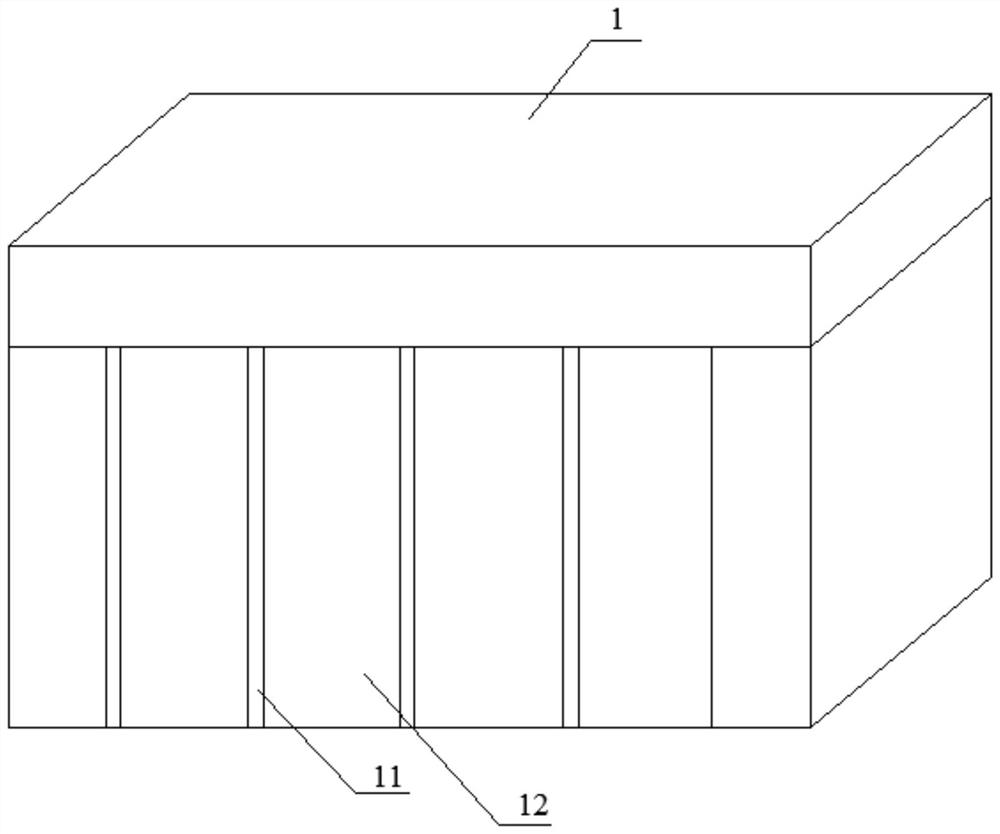

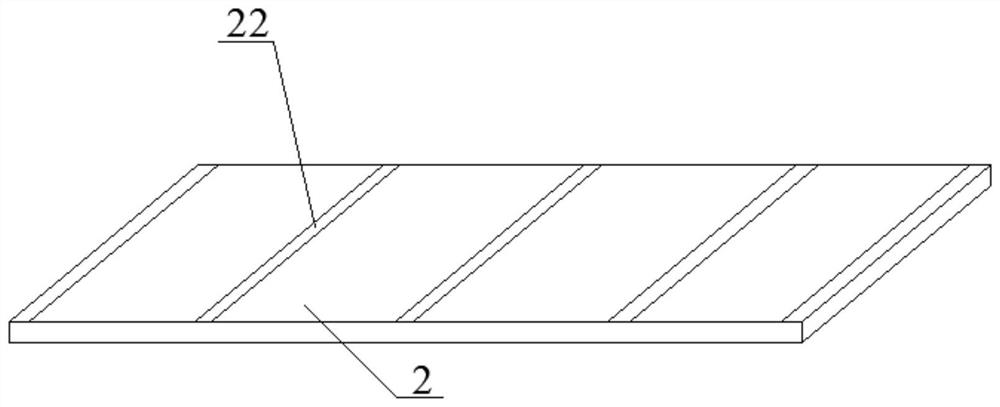

[0039] A granary that prevents mildew during grain storage, such as Figure 1-2 , Figure 6-7As shown, it includes a granary main body 1, and the granary main body 1 includes a wall and a roof built on the ground. The inside of the granary main body 1 is divided into several storage areas 12 by 2-4 partition walls 11, and each of the storage areas The front side of the area 12 is provided with a door for entering and exiting grain, and the top of each storage area 12 is provided with a feeding port, and the interior of the granary main body 1 is provided with an airing platform above all the storage areas 12. The airing platform includes several airing tables 2, table lifting devices, grain flattening devices and controllers, the number of the airing table 2 is equal to that of the storage area 12 and the positions correspond one by one, and the adjacent airing tables 2 The tabletops 2 are rotationally connected by the rotating shaft 22, so that any two adjacent airing tablet...

Embodiment 2

[0044] A kind of anti-mildew granary in the process of grain storage, the anti-mildew plate added on the basis of the granary structure in Example 1, and the partition wall 11 of each storage area 12 is detachably laid on the wall by buckling The anti-mildew board is installed, whenever a storage area 12 is vacated, the damp anti-mildew board in the storage area 12 is disassembled, and a new anti-mildew board is replaced. The damp anti-mildew board that has been replaced is dried and reused next time.

[0045] It should be noted that, in the granary structure of the present invention, the "front" refers to the side direction for people to enter the granary, and the "rear" orientation is opposite to the "front" orientation.

Embodiment 3

[0047] Based on the same inventive concept, the present invention also provides a mildew-proof board with mildew-proof and moisture-absorbing effects, the mildew-proof board includes a moisture-absorbing layer and an anti-mildew coating coated on the outer surface of the moisture-absorbing layer, and the moisture-absorbing layer is For wooden boards, the anti-mildew coating is made of the following raw materials in parts by weight: 40 parts of thermoplastic acrylic resin, 3 parts of diatomaceous earth, β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl chloride 0.05 parts, 3 parts of curing agent epoxy resin.

[0048] The preparation method of the mildew-proof board is as follows:

[0049] Step 1, weigh each component according to the following parts by weight: 40 parts of thermoplastic acrylic resin, 3 parts of diatomaceous earth, 0.05 part of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl chloride, solidify 3 parts epoxy resin.

[0050] Step 2: Heat and melt the thermoplasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com