Mixing device for production of polyethylene glycol

A mixing device and polyethylene glycol technology, applied in the field of mixing equipment, can solve the problems of low production efficiency of polyethylene glycol, inability to achieve uniform mixing, no automatic cleaning, etc., to achieve self-cleaning, saving pipes and equipment, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

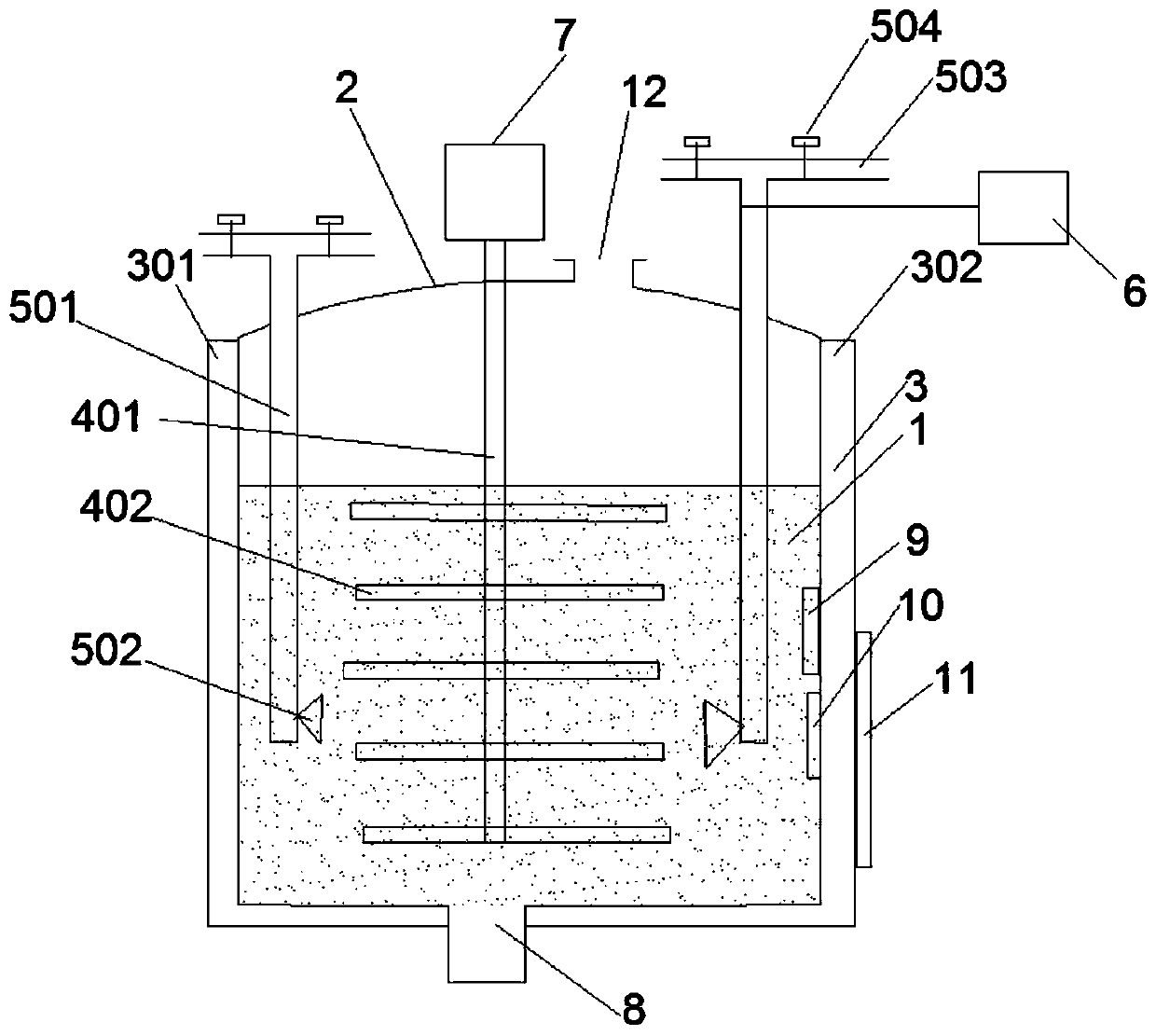

[0028] see figure 1 ,

[0029] A mixing device for polyethylene glycol production, comprising a reaction tank body 1, a reaction tank cover 2, a circulating water chamber 3, a stirring assembly, a feeding assembly, a feeding motor 6, a stirring motor 7, a discharge port 8, a temperature sensor 9, pH sensor 10, display screen 11,

[0030] The stirring assembly includes a stirring shaft 401 and at least one stirring paddle 402, the stirring shaft 401 passes through the through hole of the stirring shaft and is connected with the stirring motor 7, and the stirring motor 7 drives the stirring shaft 401 to move;

[0031] The reaction tank cover 2 is provided with a stirring shaft through hole, a feed pipe through hole and an air extraction opening 12,

[0032] The seal between the reaction tank body 1 and the reaction tank cover 2 is sealed by a gasket or a spherical line seal between the reaction tank body 1 and the reaction tank cover 2. Both of them use the main bolts evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com