A Method for Removing Carbon Deposition in Compressor Airway

A technology for compressors and carbon deposition, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as long replacement cycles, heavy work, and unrealizable cleaning, so as to reduce operating intensity, Ease of operation and improvement of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

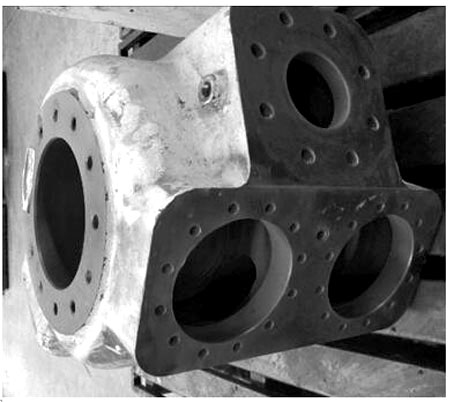

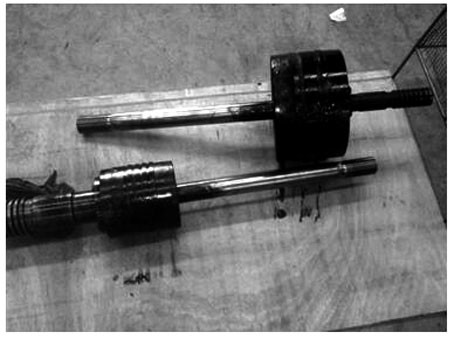

[0016] Example 1: Carbon deposit cleaning steps for our company's D121 products (pipes, coolers, separators, buffer tanks, cylinders, pistons, etc.):

[0017] A method for removing carbon deposits in an air passage of a compressor, the specific implementation steps are as follows:

[0018] (1) Take 3kg of sodium hydroxide (NaOH) and add it to 100L of water, stir and mix to make a NaOH solution;

[0019] (2) Put the cylinder in the heating tank (steel iron tank with a length of 2500mm, a width of 750mm, and a height of 700mm), so that the cylinder is completely submerged in the solution and is 30mm below the liquid level, and heated to boiling, and then continue to heat for 1 hour;

[0020] (3) Cover the heating tank and keep it warm for 8 hours so that the cylinder is immersed in the boiling liquid, then take out the cylinder and rinse it with clean water 3 times to remove all the carbon deposits, and use compressed air to blow off the water marks on the surface of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com