Gas blowing type flow control turbulence inhibitor for continuous casting tundishes

A continuous casting tundish and suppressor technology, which is applied in the direction of casting molten material containers, casting equipment, manufacturing tools, etc., can solve the problems of easy erosion and erosion of stoppers, secondary pollution of molten steel, etc., and achieve easy popularization and application, The effect of improving quality and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

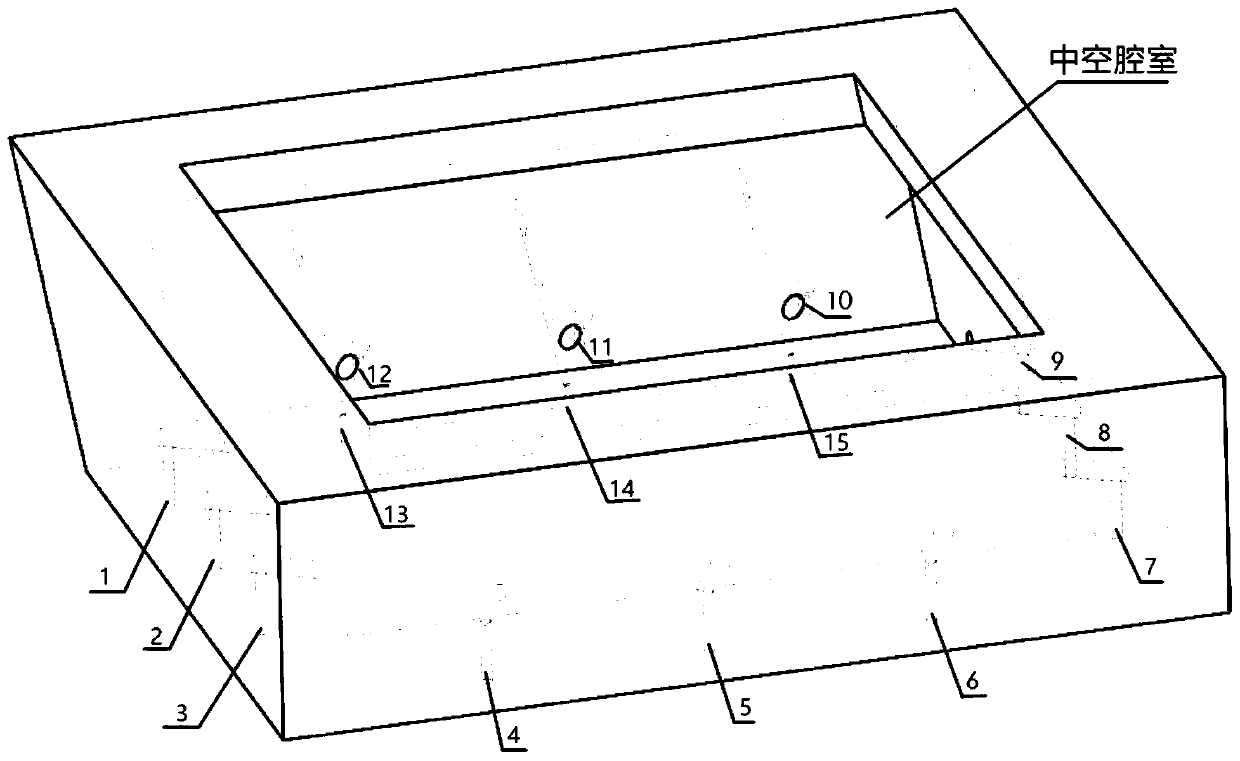

[0033] In this example, see figure 1 , figure 2 and Figure 7 , a continuous casting tundish air blowing type flow control turbulence suppressor, which is installed in a single-flow tundish, as a single-flow tundish air blowing type turbulence suppressor, the suppressor forms a hollow inverted quadrangular truss structure with an open top, The turbulence suppressor chamber forms an upward expansion form. The three side walls of the turbulence suppressor are perpendicular to the bottom of the tundish, and one side wall is inclined to the outside of the turbulence suppressor chamber. Each of the four side walls is equipped with blowing ports. The turbulence is blown in through the air pipe, and blown to each outlet respectively by the air pipe. When the air outlet is directly facing the center of the chamber of the turbulence suppressor, a cushion in the form of an air curtain will be formed at the bottom of the chamber; The air pipes in the three side walls of the device are...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

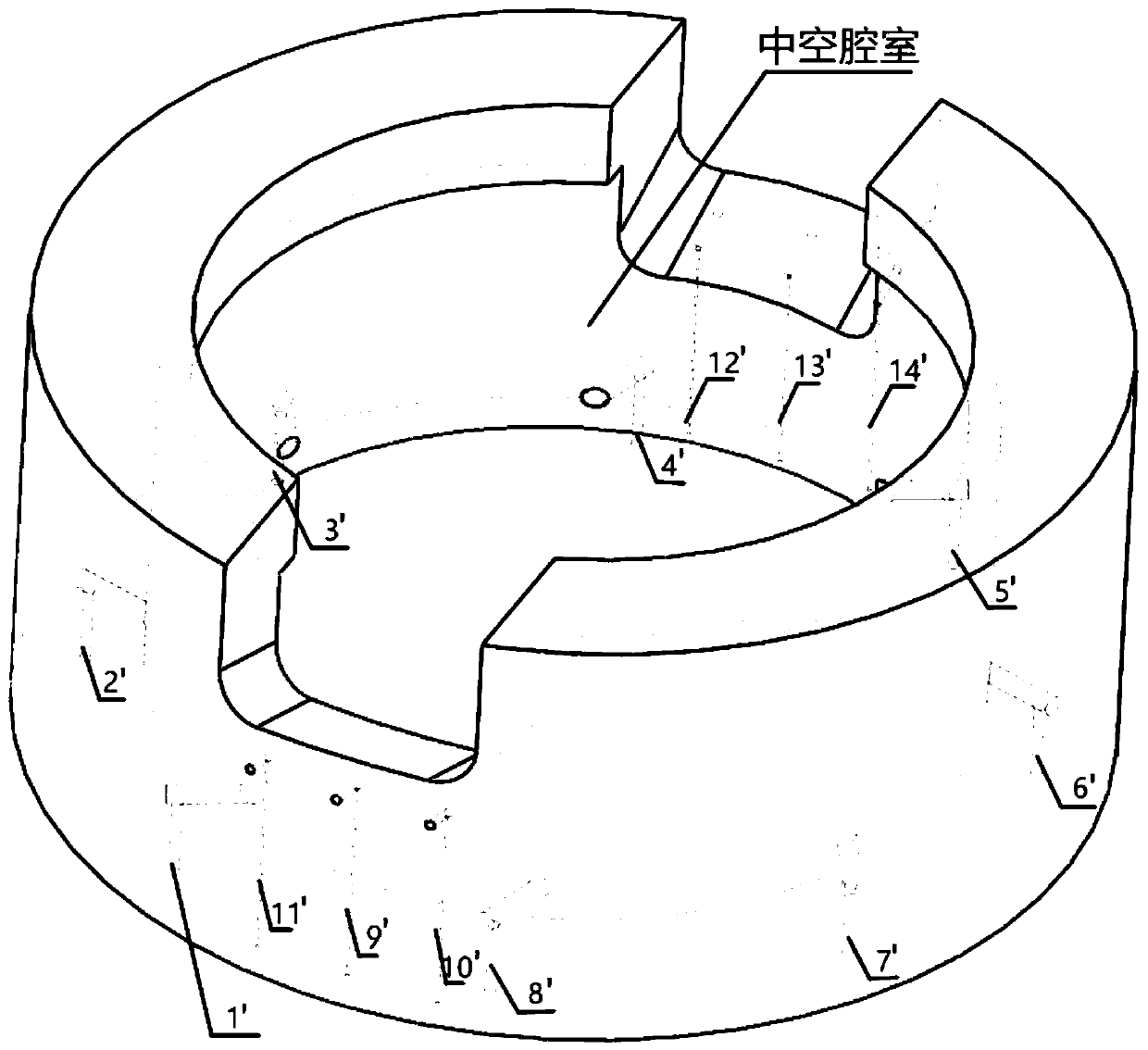

[0038] In this example, see image 3 , Figure 4 and Figure 7 , a continuous casting tundish air blowing type flow control turbulence suppressor, which is installed in the double-flow tundish, as a double-flow tundish air blowing type turbulence suppressor, the suppressor forms a cylindrical basin structure with an open top, and the turbulence suppressor cylinder The side wall is perpendicular to the bottom surface of the tundish, and the side wall is symmetrically opened with square steel liquid flow grooves with rounded corners to form a flow guide device. The upper opening has convex ribs with closing structure to form a flow-blocking structure. The gas delivery pipe is buried in the refractory material layer on the side wall of the turbulence suppressor chamber. Several air blowing ports are evenly distributed on the annular side wall. The air pipes are blown in separately, and the air ...

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this example, see Figure 5 , Figure 6 heat exchange Figure 7 , when the tundish is a multi-flow tundish, the suppressor forms a cylindrical basin structure with an open top, the cylindrical side wall of the turbulence suppressor is perpendicular to the bottom surface of the tundish, and there are at least two square steel liquid flows with rounded corners on the side wall The flow center line of the two square steel liquid flow grooves forms a diversion and diversion device with an acute angle relationship. The bottom of the square steel liquid flow groove is inclined to the outside of the turbulence suppressor chamber to form a slope. There are convex ribs with a closing structure at the mouth to form a flow blocking structure. The gas delivery pipe is buried in the refractory material layer on the side wall of the turbulence suppressor chamber. Several air ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap