Plunger type continuous extrusion device for additive manufacturing of energetic material

A technology of additive manufacturing and extrusion equipment, which is applied in the field of energetic material additive manufacturing plunger type continuous extrusion equipment, which can solve the problem of poor control stability of pneumatic extrusion, difficulty in controlling extrusion speed, and limited size of molded parts To achieve the effect of improving melting efficiency and thermal uniformity, ensuring material temperature consistency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

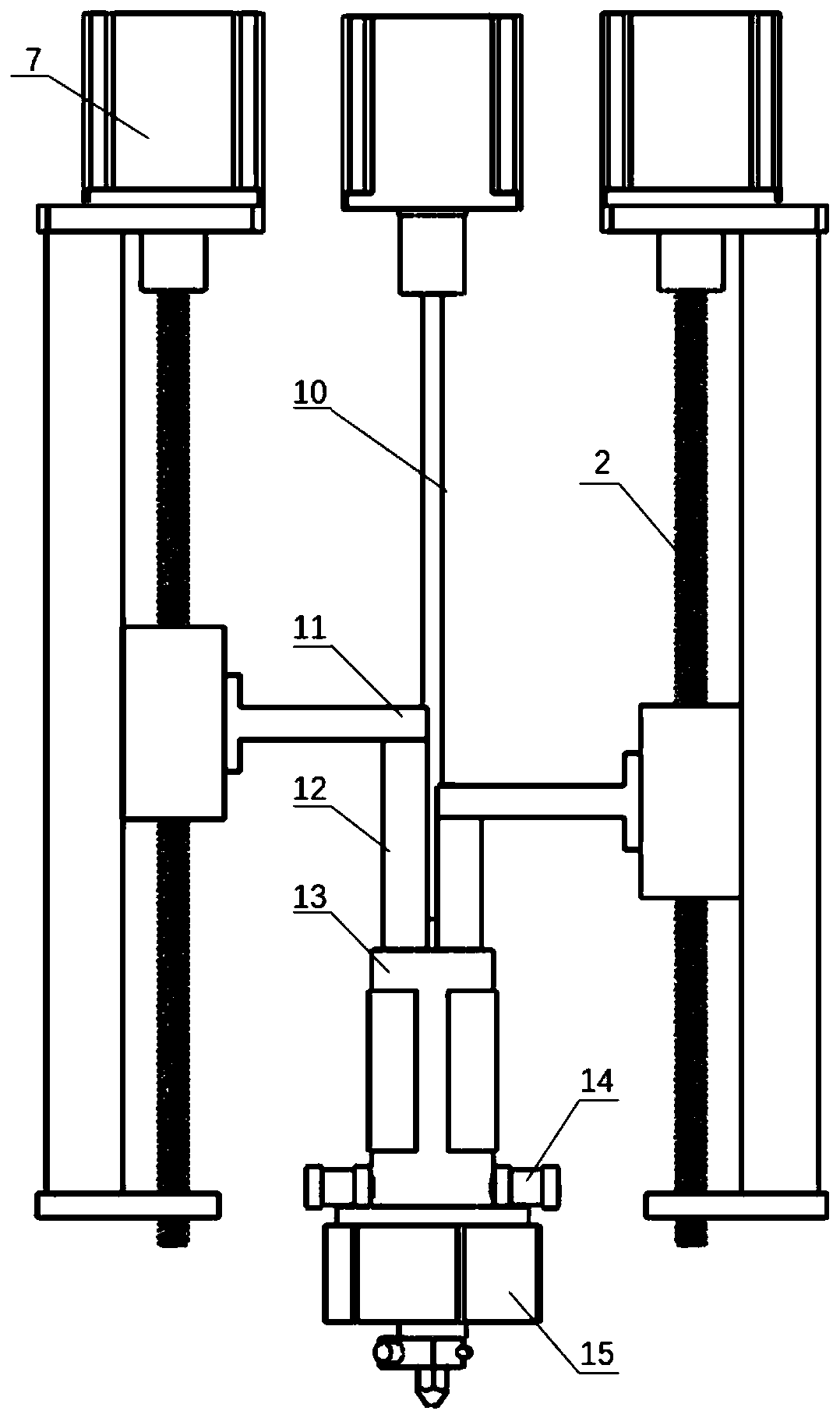

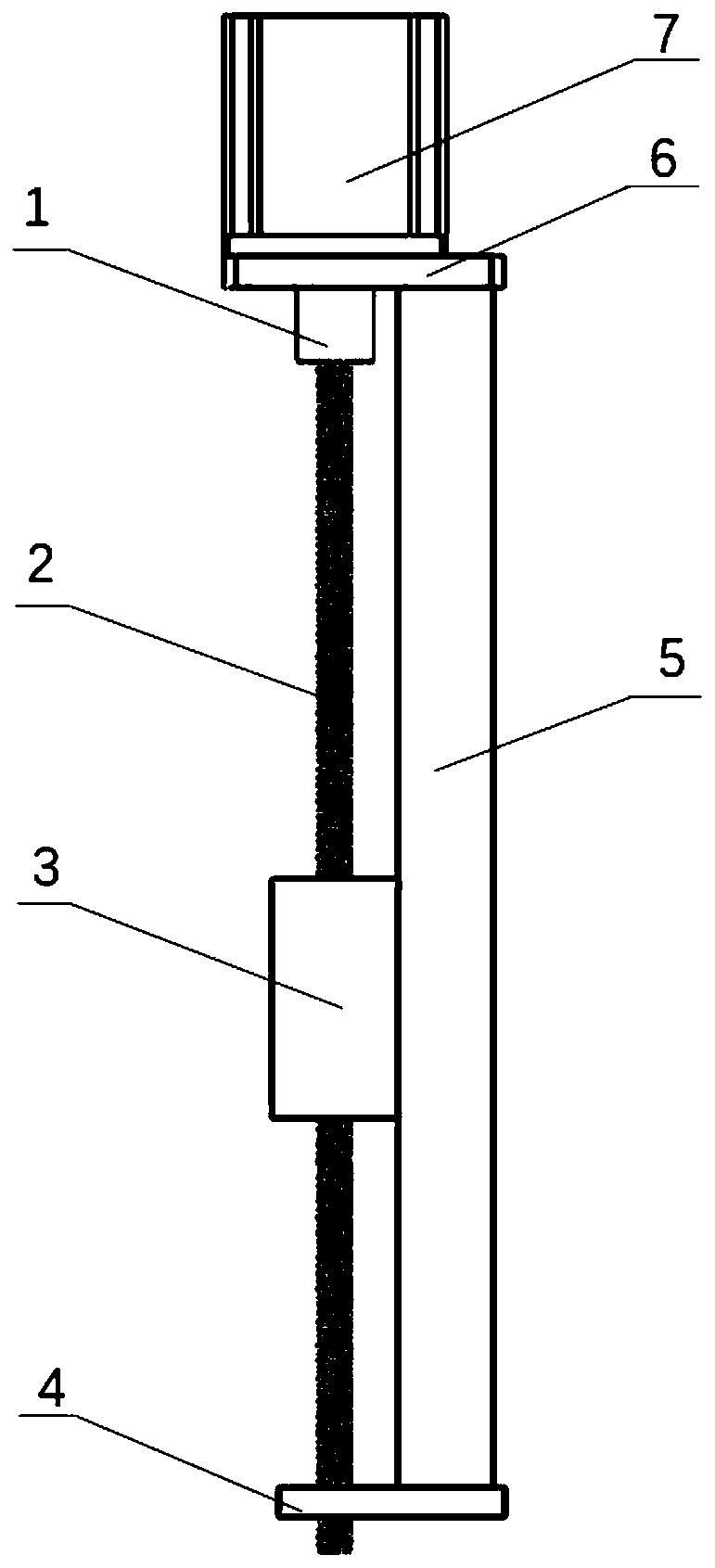

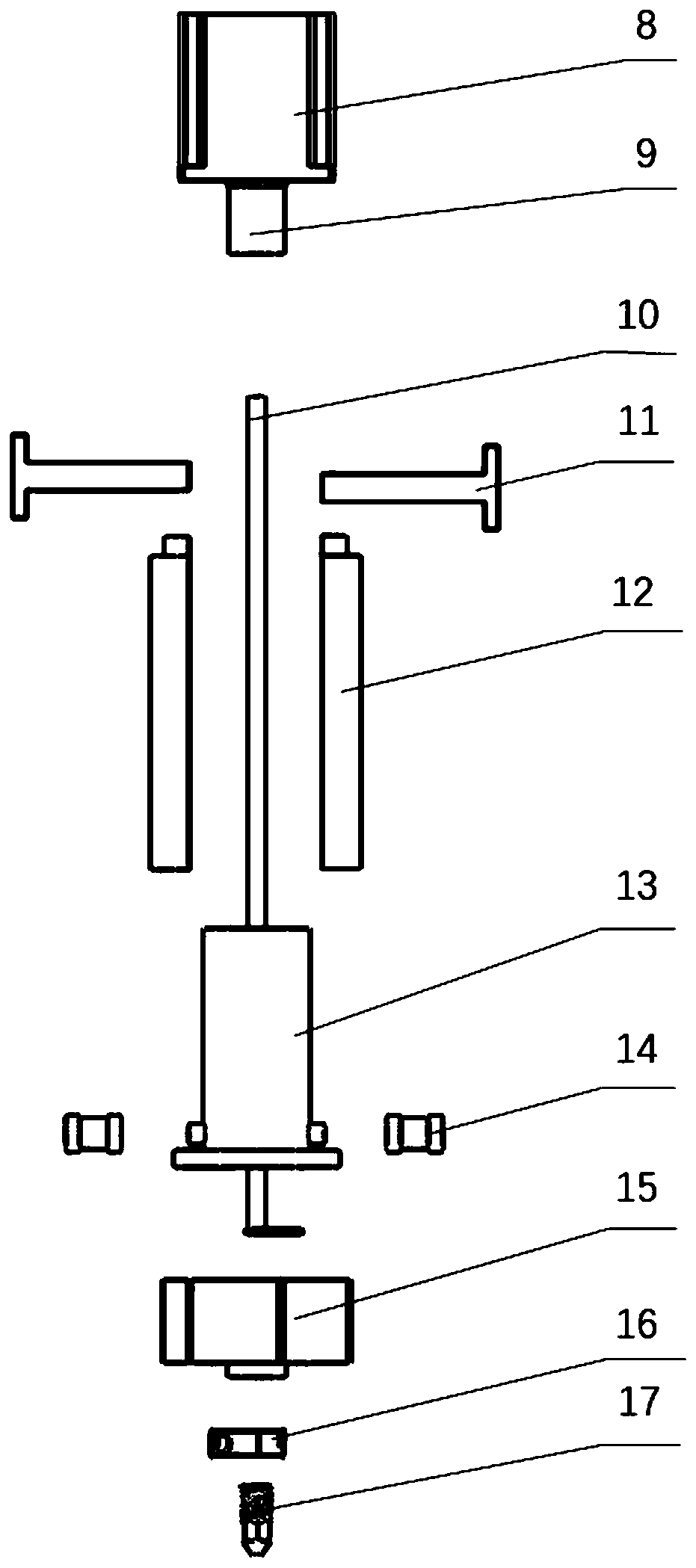

[0020] to combine Figure 1 to Figure 6 , a plunger-type continuous extrusion device for additive manufacturing of energetic materials, including a temperature control system, an extrusion system, two transmission systems and two plunger connectors 11, the two transmission systems are symmetrically arranged on both sides of the extrusion system The two sides are respectively connected to the extrusion system through the plunger connector 11, and the temperature control system is fixed on the extrusion system.

[0021] The extrusion system includes a barrel 13, a rotating assembly 10, a connecting flange 15, a nozzle cover 16, a nozzle 17, a first coupling 9, a first stepping motor 8, two plunger rods 12 and two single Directional valve 14; Machine barrel 13 comprises cylinder 13-1, circular tube 13-2 and two connecting plates 13-3, and circular tube 13-2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com