A mine hoist tension fault diagnosis method, system and control system

A fault diagnosis system and mine hoist technology, applied in elevators, computer parts, instruments, etc., can solve problems such as tension fault detection methods or poor system practicability, and achieve long-term stable and reliable operation, improve service life, and maintenance costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

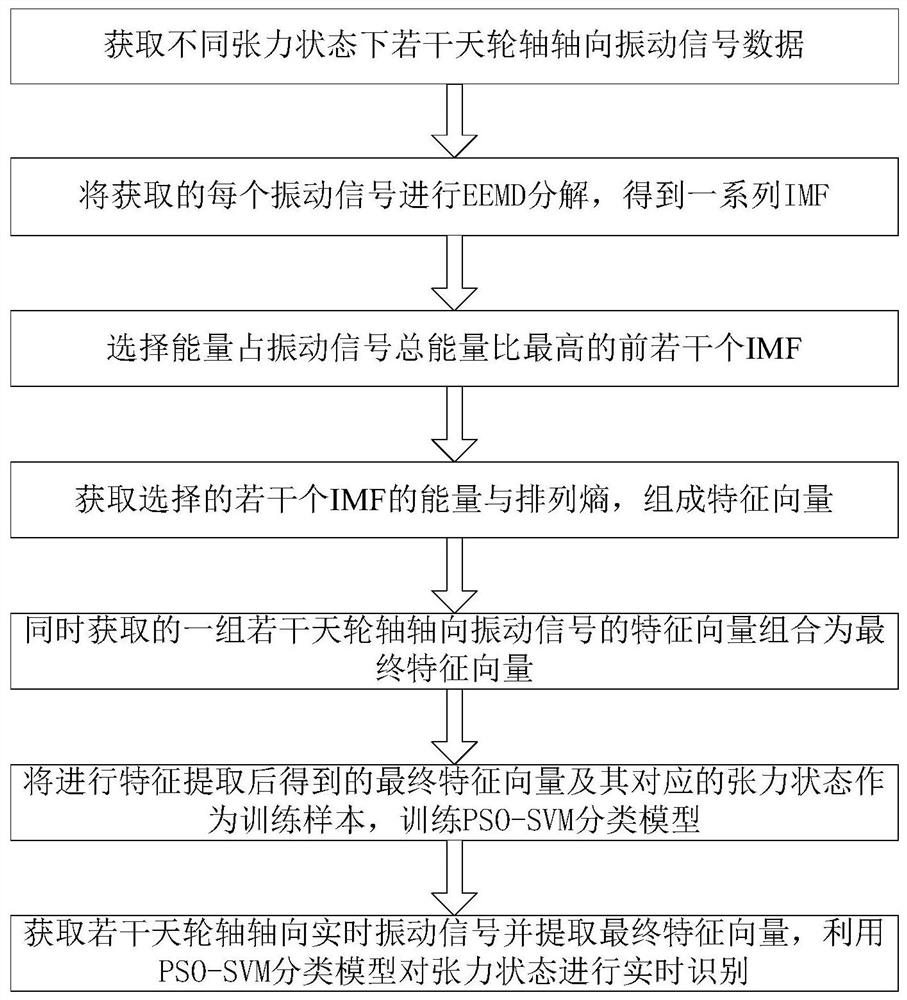

[0051] The invention provides a mine hoist tension fault diagnosis method, such as figure 1 shown, including the following steps,

[0052] Model building phase:

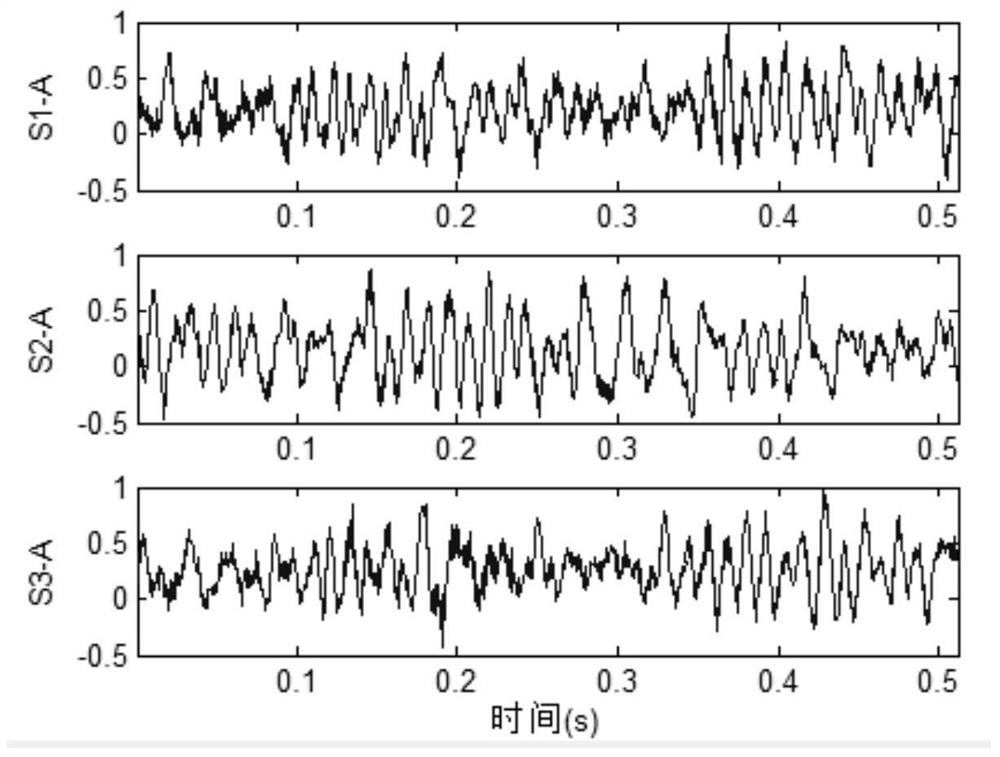

[0053] Acquire the axial vibration signal data of several sky wheel shafts under different tension states. In this embodiment, two axial vibration signals of the sky wheel shaft are collected. To achieve a balance between, in this embodiment, the signal segment with a duration of 1s is selected to be intercepted, image 3 The axial vibration waveforms of a single rope under three working conditions of overload (S1-A), normal (S2-A), and underload (S3-A) are shown.

[0054] Feature extraction, EEMD decomposition is performed on each acquired vibration signal, and each vibration signal is decomposed into a series of IMFs. EEMD is an adaptive signal decomposition method for non-stationary nonlinear signals. For a vibration signal x(t), EEMD decomposes it into a series of IMF c k (t) and the residual term r m (t), ...

Embodiment 2

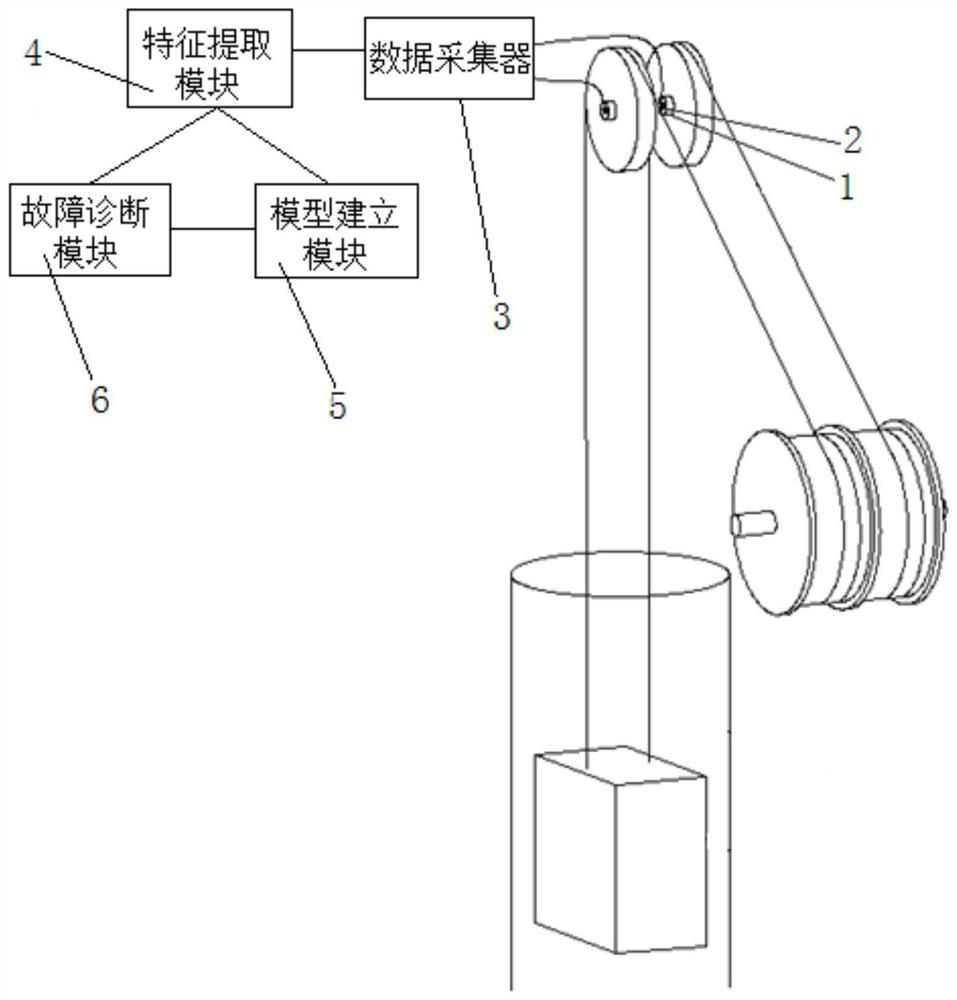

[0068] The invention provides a mine hoist tension fault diagnosis system, comprising:

[0069] Several vibration sensors 2 are used to obtain axial vibration signals of several sky wheel shafts 1;

[0070] The data collector 3 is used to transmit the vibration signals obtained by the plurality of vibration sensors 2 to the feature extraction module 4;

[0071] The feature extraction module 4 is used to extract the features of the vibration signal transmitted by the data collector 3, decompose each vibration signal into EEMD, decompose each vibration signal into a series of IMFs, and select the one with the highest ratio of energy to the total energy of the vibration signal For the first several IMFs, the energy and permutation entropy of the selected several IMFs are obtained, and the feature vectors are formed, and the feature vectors of a group of simultaneously obtained axial vibration signals of the wheel shaft are combined into the final feature vector;

[0072] Model b...

Embodiment 3

[0085] The present invention provides a mine hoist control system, which includes the above-mentioned mine hoist tension fault diagnosis system and a control unit connected with the mine hoist tension fault diagnosis system. During specific implementation, the mine hoist tension fault diagnosis system provided in Embodiment 2 can be connected with the main control PLC of the mine hoist, and a wired connection or a wireless connection can be used to realize the mine hoist tension fault diagnosis system and the mine hoist. The main control PLC communication, the mine hoist tension fault diagnosis system transmits the tension state information to the main control PLC, which can deal with the identified tension faults in real time and provide mine production safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com