Double-component polyurethane sealant and preparation method and application thereof

A two-component polyurethane and sealant technology, applied in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of difficult reinforcement, poor adhesion and shock resistance, and metal spacers Easy to damage the hollow structure and other problems, to achieve the effect of reducing the risk of destroying the hollow structure, fast curing speed, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

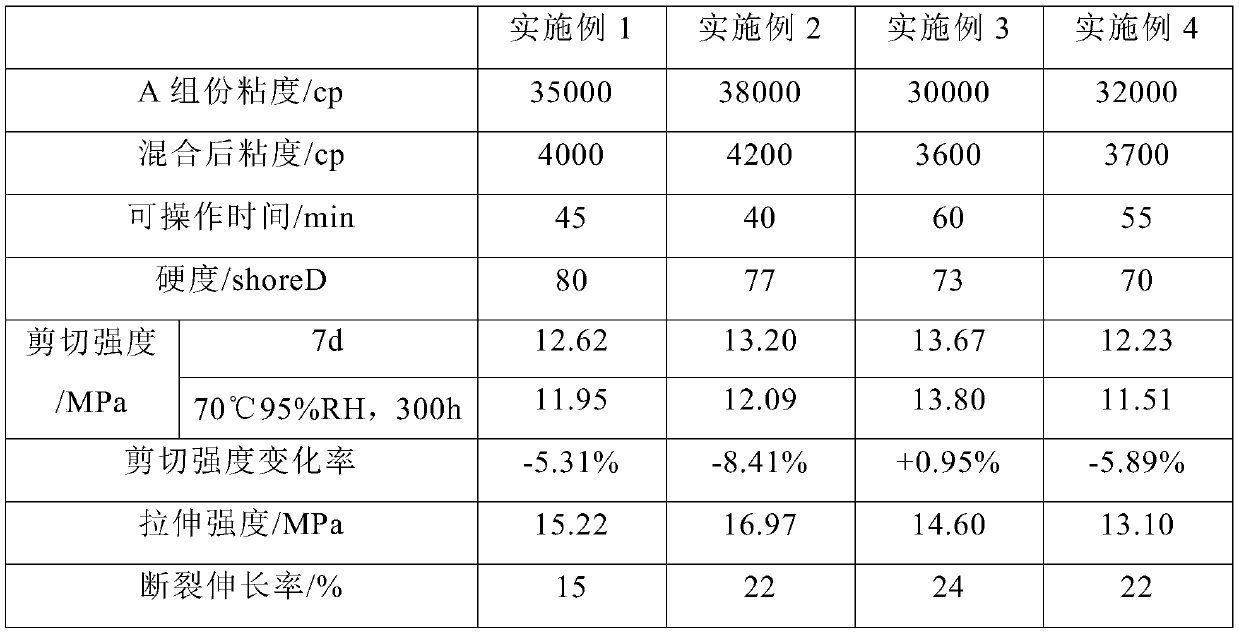

Examples

preparation example Construction

[0047] In some embodiments, the preparation method of hydroxyl-terminated polyurethane prepolymer comprises:

[0048] First, add polyol and aliphatic isocyanate to the reaction kettle, and carry out a stirring reaction at a constant temperature of 75°C to 80°C for 0.5h to 1.0h in a vacuum environment with a vacuum degree of -0.09MPa to -0.10MPa;

[0049] Then, remove the vacuum environment, add 0.01 to 0.05 parts of the second catalyst in the reactor, and continue to carry out the secondary stirring reaction at a constant temperature of 75°C to 80°C for 2.0h to 3.0 hours under a vacuum environment with a vacuum degree of -0.09MPa to -0.10MPa h;

[0050] Then, remove the vacuum environment, add 0.01 to 0.05 parts of the second catalyst to the reactor, and continue to carry out three stirring reactions at a constant temperature of 75 ° C to 80 ° C for 0.5 h to After 2.0 h, a hydroxyl-terminated polyurethane prepolymer was obtained.

[0051] In some embodiments, after three sti...

Embodiment 1

[0063] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0064] Add 700 g of polyether triols with a molecular weight of 500 and 100 g of polytetrahydrofuran diols with a molecular weight of 650 into a three-necked flask, heat to 100° C., and stir the reaction under a vacuum environment with a vacuum of -0.09 MPa while dehydrating. About 1~2h;

[0065] Then, the temperature of the three-necked flask was lowered to 75°C, nitrogen gas was introduced to release the vacuum environment, 200 g of isophorone diisocyanate was added to the three-necked flask, the vacuum was continued to carry out a stirring reaction for 0.5 h, about 0.01 g of bismuth laurate was added, and the pumping was continued. The second stirring reaction was carried out in vacuum for 2.5 hours, and then about 0.01 g of bismuth laurate was added, and the vacuum was continued to carry out three stirring reactions for 1 hour. After that, the temperature was lowered to 60° C. and stored for later use....

Embodiment 2

[0070] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0071] Add 600 g of polyether triols with a molecular weight of 500 and 200 g of polytetrahydrofuran diols with a molecular weight of 650 in a three-necked flask, heat to 120° C., and stir the reaction in a vacuum environment with a vacuum of -0.10 MPa while dehydrating. About 1~2h;

[0072] Then, the temperature of the three-necked flask was lowered to 78°C, nitrogen gas was introduced to release the vacuum environment, 175 g of isophorone diisocyanate was added to the three-necked flask, the vacuum was continued to carry out a stirring reaction for 0.5 h, about 0.01 g of bismuth laurate was added, and the pumping was continued. The second stirring reaction was carried out in vacuum for 2.5 hours, and then about 0.01 g of bismuth laurate was added, and the vacuum was continued to carry out three stirring reactions for 1 hour. After that, the temperature was lowered to 60° C. and stored for later use.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com