Hectorite-rhodamine hybrid fluorescent material and its preparation method and application

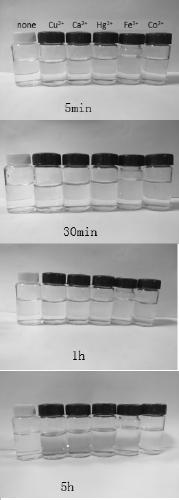

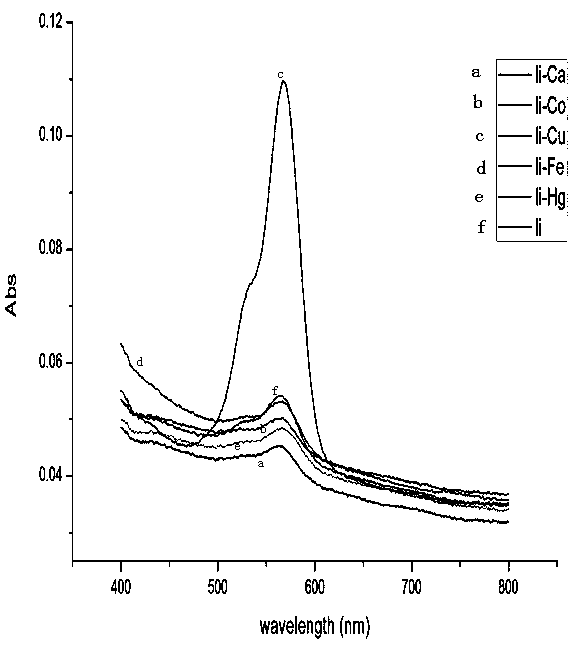

A fluorescent material and hectorite technology, applied in the field of heavy metal detection, can solve the problems of poor water solubility, decreased sensitivity of fluorescent probes, easy precipitation, etc., and achieve the effects of obvious color change, improved water solubility, and large fluorescence change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] One, according to the following route synthetic rhodamine dye

[0039] 1. Synthesis of rhodamine hydrazide

[0040]

[0041] After adding 18.00 g (37.6 mmol) of Rhodamine B into a 250 mL round bottom flask, about 120 mL of ethanol was added to dissolve it. With vigorous stirring at room temperature, 48.0 mL of excess hydrazine hydrate (80%) was added dropwise. After the dropwise addition, stir and heat to reflux for 2 h, the solution turns from dark purple to bright and clear orange. After the mixture was cooled to room temperature, the solvent was removed under reduced pressure. About 10 M HCl solution was added to the above flask until there was no solid and the solution turned into a clear red solution, at which point the pH of the solution was about 1. Afterwards, the above solution was transferred to a 250 mL beaker, and about 10 M NaOH solution was slowly added with stirring until the pH of the solution was about 10. Finally, the precipitate in the solution...

Embodiment 2

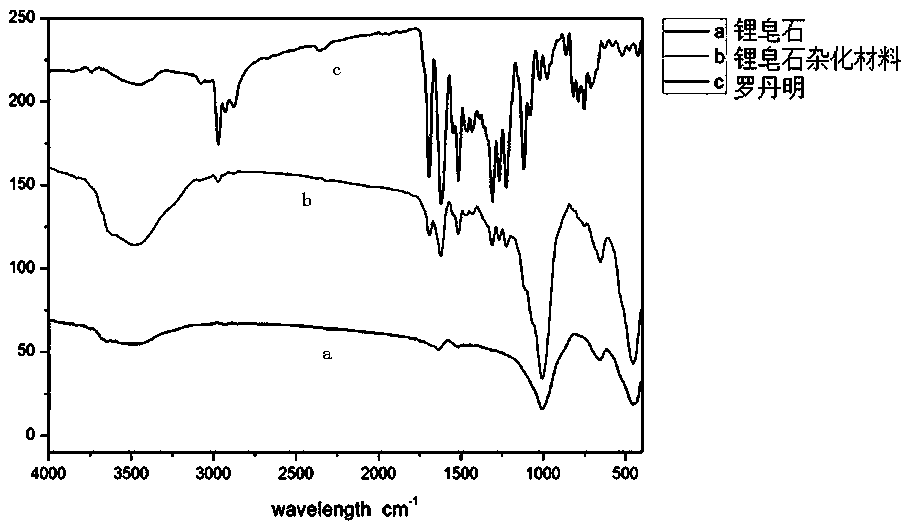

[0049] Preparation of hectorite-rhodamine hybrid fluorescent material

[0050]Grinding: Take 0.24 g of synthetic laponite and 0.08 g of rhodamine dye and mix them evenly in an agate mortar, and grind the sample for 8 min until the color is light red.

[0051] Baking: take the ground mixed sample, place it in a vacuum drying oven at 100° C. and bake for 15 hours to obtain the hectorite-rhodamine hybrid fluorescent material.

Embodiment 3

[0053] Preparation of hectorite-rhodamine hybrid fluorescent material

[0054] Grinding: Take 0.64 g of synthetic laponite and 0.08 g of rhodamine dye and mix them evenly in an agate mortar, and grind the sample for 15 min until the color is light red.

[0055] Baking: Take the ground mixed sample, put it in a vacuum drying oven at 140° C. and bake for 10 hours to obtain the laponite-rhodamine hybrid fluorescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com