A imprinted material with high recognition ability for icariin and its preparation method

An imprinting material, icariin technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inability to purify with trace substances, poor selectivity, time-consuming, etc., and achieves simple operation, high affinity, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

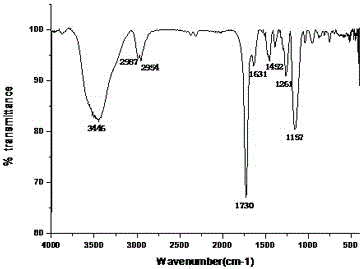

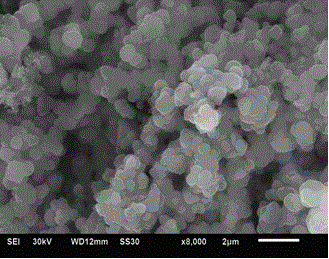

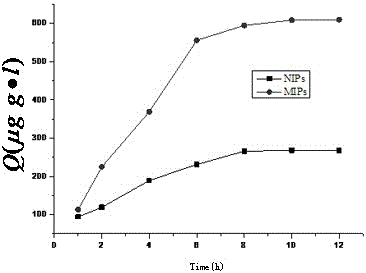

Image

Examples

Embodiment 1

[0034] Example 1: An imprinted material (MIPs) with a high ability to recognize icariin. The mass percentages of the components required to prepare the imprinted material are: 0.10% icariin, 0.02% acrylamide, 1.22% Ethylene glycol dimethacrylate, 0.10% azobisethylbutyronitrile and 98.56% methanol-acetonitrile mixed solvent.

[0035] The mixed solvent is a mixed solution of methanol and acetonitrile in a volume ratio of 3:1.

[0036] Its preparation method is as follows:

[0037] A. Add 0.10% icariin, 0.02% acrylamide and 98.56% methanol-acetonitrile mixed solvent in the reaction kettle by mass percentage, stir at room temperature for 6 hours, and then let stand for 1 hour to make it fully pre-polymerized;

[0038] The volume ratio of the methanol-acetonitrile mixed solution is 3:1;

[0039] B. After pre-polymerization, add 1.22% ethylene glycol dimethacrylate and 0.10% azobisethylbutyronitrile respectively by mass percentage, ultrasonically degas for 15 minutes, then fill wi...

Embodiment 2

[0043] Example 2: An imprinted material (MIPs) with a high ability to recognize icariin. The mass percentages of the components required to prepare the imprinted material are: 0.10% icariin, 0.11% acrylamide, 1.22% Ethylene glycol dimethacrylate, 0.10% azobisethylbutyronitrile and 98.47% methanol-acetonitrile mixed solvent.

[0044] The mixed solvent is a mixed solution of methanol and acetonitrile in a volume ratio of 3:1.

[0045] Its preparation method is as follows:

[0046]A. Add 0.10% icariin, 0.11% acrylamide and 98.47% methanol-acetonitrile mixed solvent in the reaction kettle by mass percentage, stir at room temperature for 6 hours, and then let stand for 1 hour to make it fully pre-polymerized;

[0047] The volume ratio of the methanol-acetonitrile mixed solution is 3:1;

[0048] B. After pre-polymerization, add 1.22% ethylene glycol dimethacrylate and 0.10% azobisethylbutyronitrile respectively by mass percentage, ultrasonically degas for 15 minutes, then fill wit...

Embodiment 3

[0052] Example 3: An imprinted material (MIPs) with a high ability to recognize icariin. The mass percentages of the components required to prepare the imprinted material are: 0.10% icariin, 0.06% acrylamide, 2.99% Ethylene glycol dimethacrylate, 0.10% azobisethylbutyronitrile and 96.75% methanol-acetonitrile mixed solvent.

[0053] The mixed solvent is a mixed solution of methanol and acetonitrile in a volume ratio of 3:1.

[0054] Its preparation method is as follows:

[0055] A. Add 0.10% icariin, 0.06% acrylamide and 96.75% methanol-acetonitrile mixed solvent in the reaction kettle by mass percentage, stir at room temperature for 6 hours, and then let stand for 1 hour to make it fully pre-polymerized;

[0056] The volume ratio of the methanol-acetonitrile mixed solution is 3:1;

[0057] B. After pre-polymerization, add 2.99% ethylene glycol dimethacrylate and 0.10% azobisethylbutyronitrile respectively by mass percentage, ultrasonically degas for 15 minutes, then fill wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com