Magnetic core-shell imprinted material of silibinin and preparation method thereof

A technology of silibinin and imprinted materials, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems affecting silybin production, price and application, poor selectivity, waste, etc., to achieve High reusability, easy cleaning, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

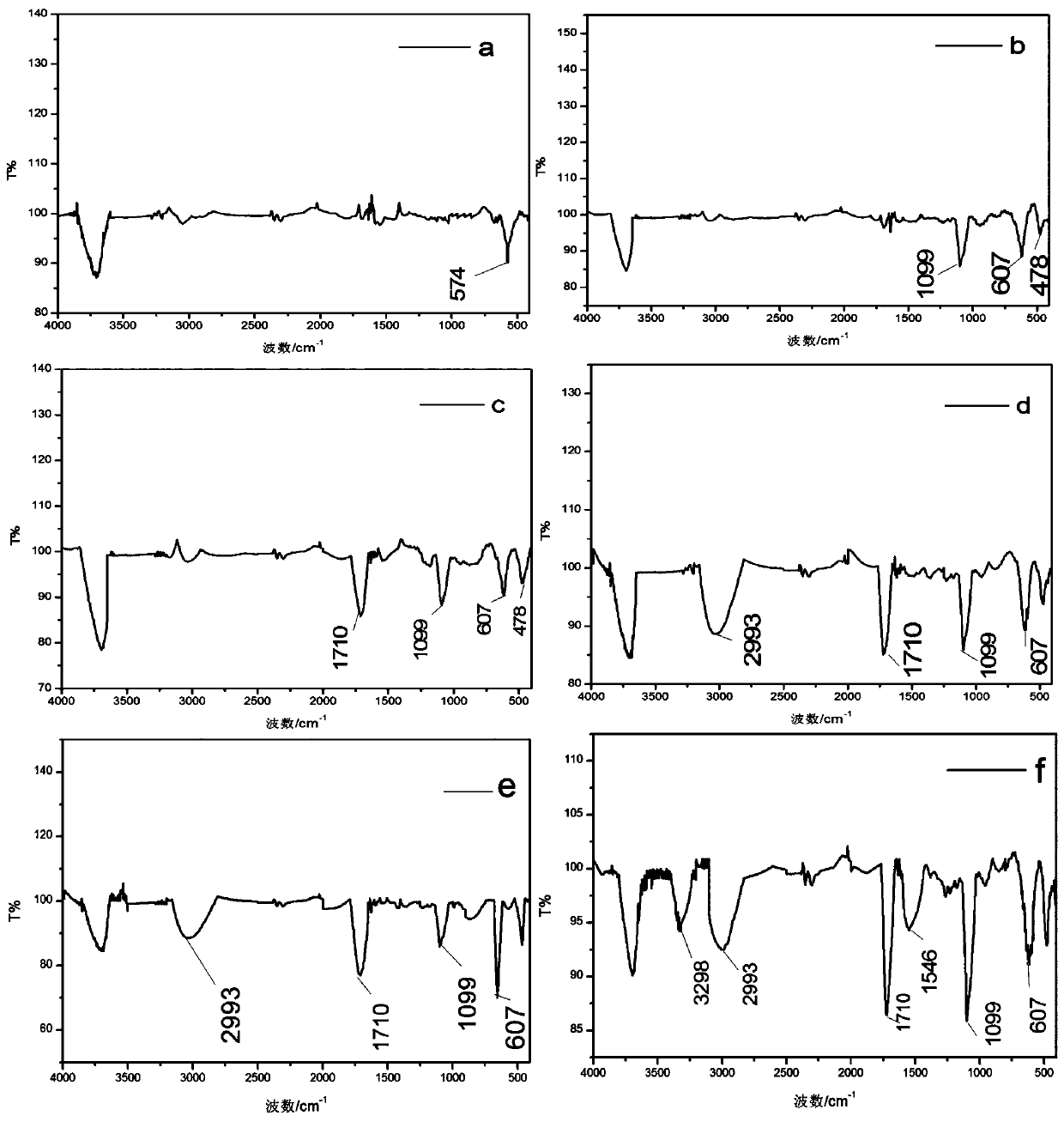

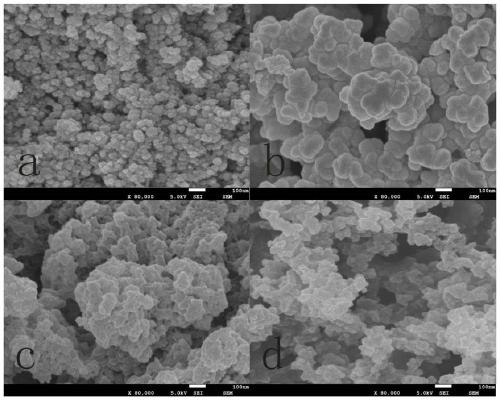

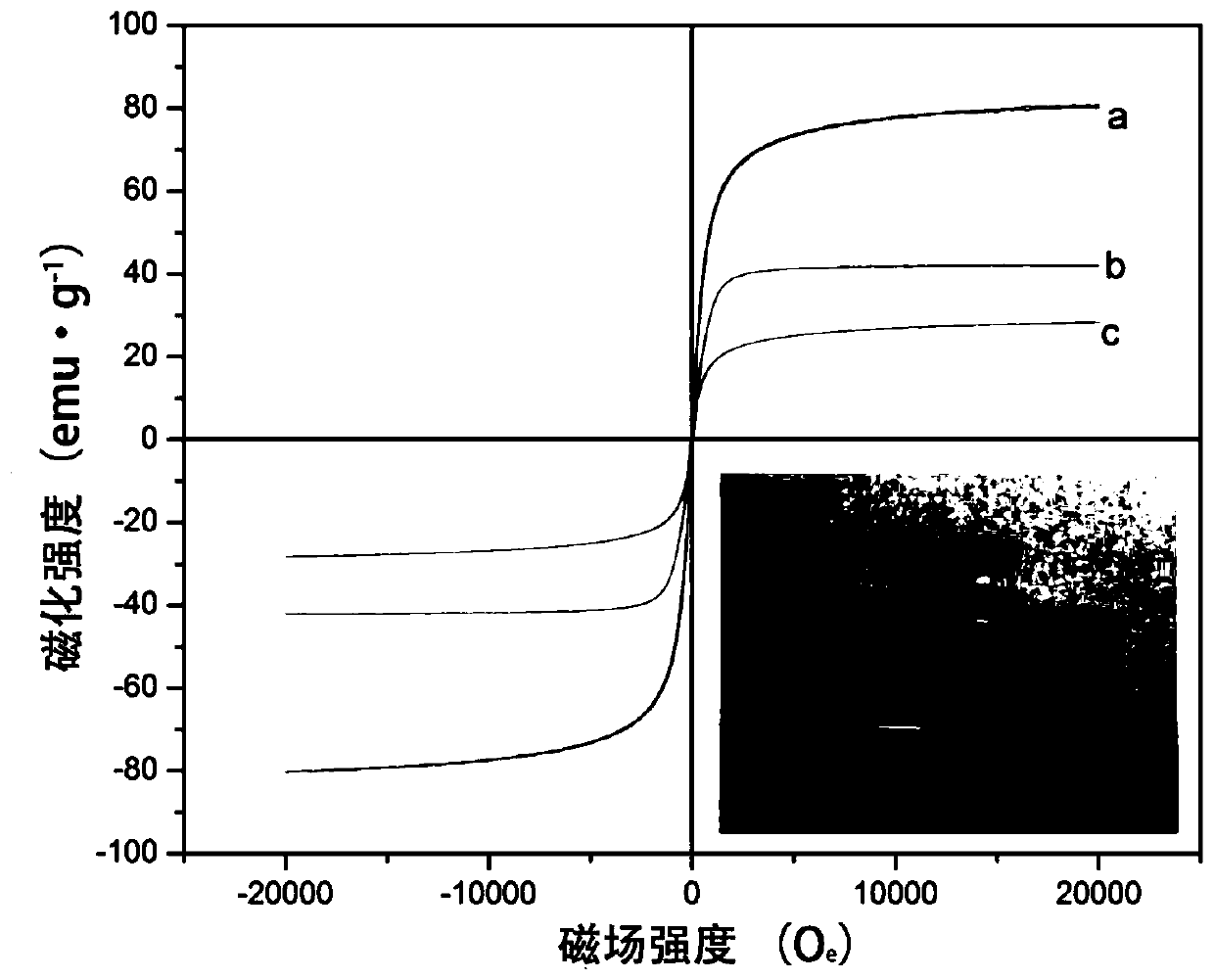

[0041] Example 1: A magnetic core-shell imprinted material that selectively adsorbs silybin, is easy to separate, easy to clean, and has a high reuse rate. The mass percentage of each component of the imprinted material is: silybin 0.220%; Methacrylic acid 0.110%; Ethylene glycol dimethacrylate 1.813%; Fe 3 o 4 &SiO 2 -MPS 0.915%; Pentamethyldiethylenetriamine 0.153%; Copper Bromide 0.091%; Azobisisobutyronitrile 0.549%; Acetonitrile 96.149%;

[0042] Its preparation method is as follows:

[0043] a. Add 0.220% silibinin, 96.149% acetonitrile and 0.110% methacrylic acid MAA to a round bottom flask by mass percentage, and place it in an orbital shaker for 12 hours at room temperature, so that the template molecule silibinin and functional Monomer MMA fully pre-polymerized;

[0044] b. In the above-mentioned pre-polymerization liquid, adding mass percent successively is 1.813% crosslinking agent ethylene glycol dimethacrylate (EMGDA), 0.549% initiator azobisisobutyronitrile ...

Embodiment 2

[0049] Example 2: A magnetic core-shell imprinted material that selectively adsorbs silybin and is easy to separate, easy to clean, and highly reusable. The mass percentage of each component of the imprinted material is: silybin 0.214%; Methacrylic acid 0.191%; Ethylene glycol dimethacrylate 3.527%; Fe 3 o 4 &SiO 2 -MPS 1.780%; Pentamethyldiethylenetriamine 0.148%; Copper bromide 0.089%; Azobisisobutyronitrile 0.534%; Acetonitrile 93.514%;

[0050] Its preparation method is as follows:

[0051] a. Add 0.214% silibinin, 93.514% acetonitrile and 0.191% methacrylic acid MAA in a round bottom flask by mass percentage, and place it in an orbital shaker for 12 hours at room temperature, so that the template molecule silibinin and functional Monomer MMA fully pre-polymerized;

[0052] b. In the above-mentioned pre-polymerization solution, adding mass percent successively is 3.527% crosslinking agent ethylene glycol dimethacrylate (EMGDA), 0.534% initiator azobisisobutyronitrile (...

Embodiment 3

[0057] Example 3: A magnetic core-shell imprinted material with selective adsorption on silybin, convenient separation, easy cleaning, and high reusability. The mass percentage of each component required to prepare the imprinted material is: water Silybin 0.209%; Methacrylic acid 0.261%; Ethylene glycol dimethacrylate 5.150%; Fe 3 o 4 &SiO 2 -MPS2.599%; pentamethyldiethylenetriamine 0.145%; copper bromide 0.087%; azobisisobutyronitrile 0.520%; acetonitrile 91.035%;

[0058] Its preparation method is as follows:

[0059] a. Add 0.209% silibinin, 91.035% acetonitrile and 0.261% methacrylic acid MAA in a round bottom flask by mass percentage, place it in an orbital shaker for 12 hours at room temperature, so that the template molecule silibinin and functional Monomer MMA fully pre-polymerized;

[0060] b. In the above-mentioned pre-polymerization solution, adding mass percent successively is 5.150% crosslinking agent ethylene glycol dimethacrylate (EMGDA), 0.520% initiator az...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com