A kind of additive for removing vegetable wax and method for removing vegetable wax

An additive and vegetable wax technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of low wax removal efficiency, achieve the effects of improving solvation capacity, reducing losses, and improving dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

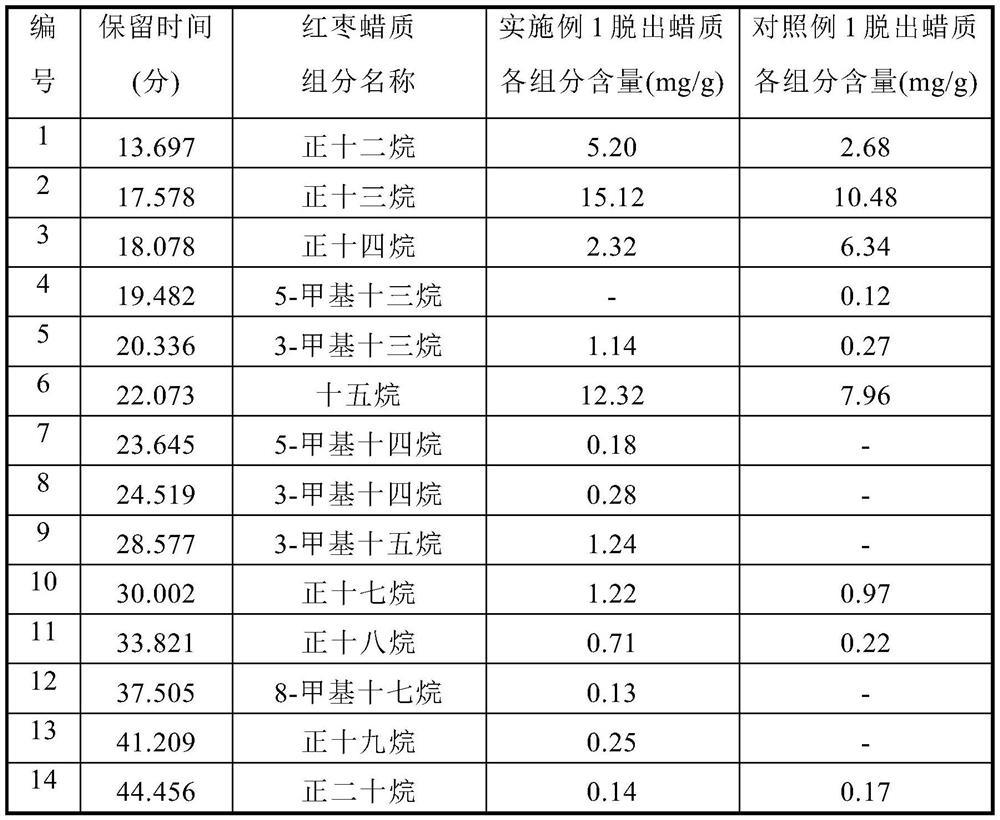

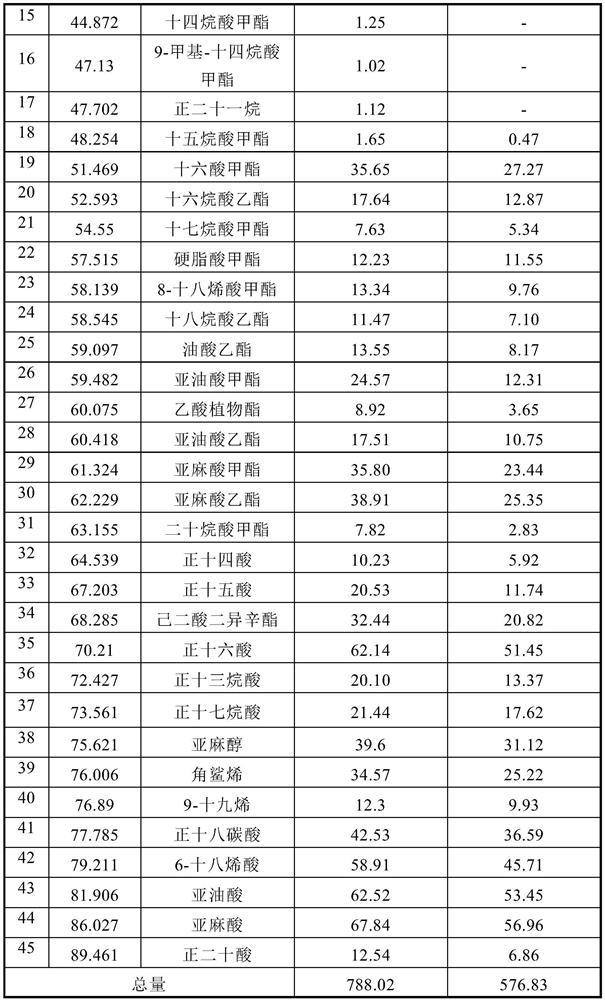

Image

Examples

Embodiment 1

[0022] This embodiment provides an additive for removing waxy jujube, which is n-stearyl alcohol tripolyoxyethylene ether.

[0023] This embodiment also provides a method for removing waxy jujube by using the above-mentioned additives, comprising: transferring 400 g of the fully dried jujube particles to a subcritical extraction kettle, and then adding 4000 mL of butane (that is, the ratio of solid to liquid is 1:10) and n-stearyl alcohol tripolyoxyethylene ether accounting for 0.3% of the mass fraction of butane were extracted at 8°C for 3.5 hours, and the extraction pressure was the saturated vapor pressure of butane at this temperature; after the extraction was completed, it was evaporated under reduced pressure, and separated Jujube wax and pretreated jujube granules are obtained. Among them, the wax removal rate of jujube was 1.52%.

[0024] It should be noted that: the removal rate of various plant waxes herein refers to the mass percentage of the plant waxes removed from...

Embodiment 2

[0037] This embodiment provides an additive for removing the waxiness of raisins, which is n-dodecyl alcohol pentapolyoxyethylene ether.

[0038] The present embodiment also provides a method for removing waxy raisins by using the above-mentioned additives, comprising: transferring 500 g of raisins to a subcritical extraction kettle, and then adding 5000 mL of butane (that is, the ratio of solid to liquid is 1:10) and accounting for the mass of butane The fraction of 0.5% n-dodecyl alcohol pentapolyoxyethylene ether was extracted at 5°C for 4 hours, and the extraction pressure was the saturated vapor pressure of butane at this temperature. After the extraction, the wax was evaporated under reduced pressure, and the raisin wax and the pretreated raisin were separated. The total extraction yield was 1.12%, and the wax removal rate of the raisin was 0.98%.

Embodiment 3

[0045] This embodiment provides an additive for removing tea wax, which is 2-octyldecyl alcohol tripolyoxyethylene ether.

[0046] The present embodiment also provides a method for removing waxy tea leaves by using the above-mentioned additives, comprising: transferring 300 g of tea leaves to a subcritical extraction kettle, and then adding 3600 mL of butane (that is, the ratio of solid to liquid is 1:12) and butane 2-octyldecyl alcohol tripolyoxyethylene ether with a mass fraction of 1% alkane was extracted at 10°C for 2.5 hours, and the extraction pressure was the saturated vapor pressure of butane at this temperature. After the extraction is completed, evaporate under reduced pressure to separate and obtain tea wax and pretreated tea leaves. Among them, the removal rate of tea wax was 1.67%.

[0047] The pretreated tea leaves after subcritical butane dewaxing were prepared by a solvent extraction method to prepare tea extracts, using 95% ethanol as a solvent with a solid-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com