High-temperature solar cavity-type heat pipe center receiver

A high-temperature heat pipe and solar energy technology, which is applied to solar collectors, components of solar collectors, and solar heat storage, can solve the problems of increased operational safety of high-temperature heat pipe receivers, failure of receivers, and poor efficiency and performance. Improvement and other issues, to achieve the effect of improving local hot spot burning, good power station characteristics, and improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

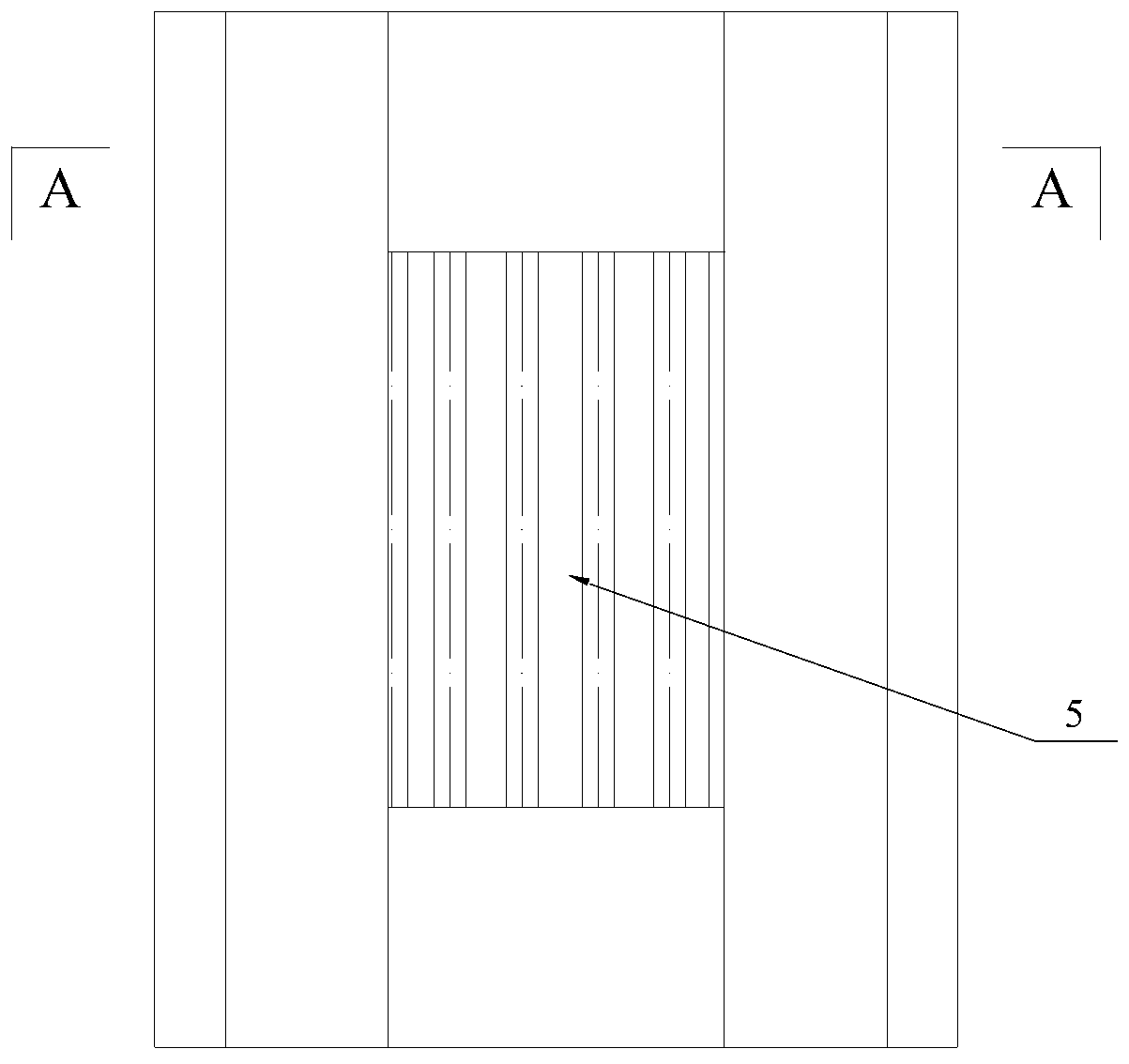

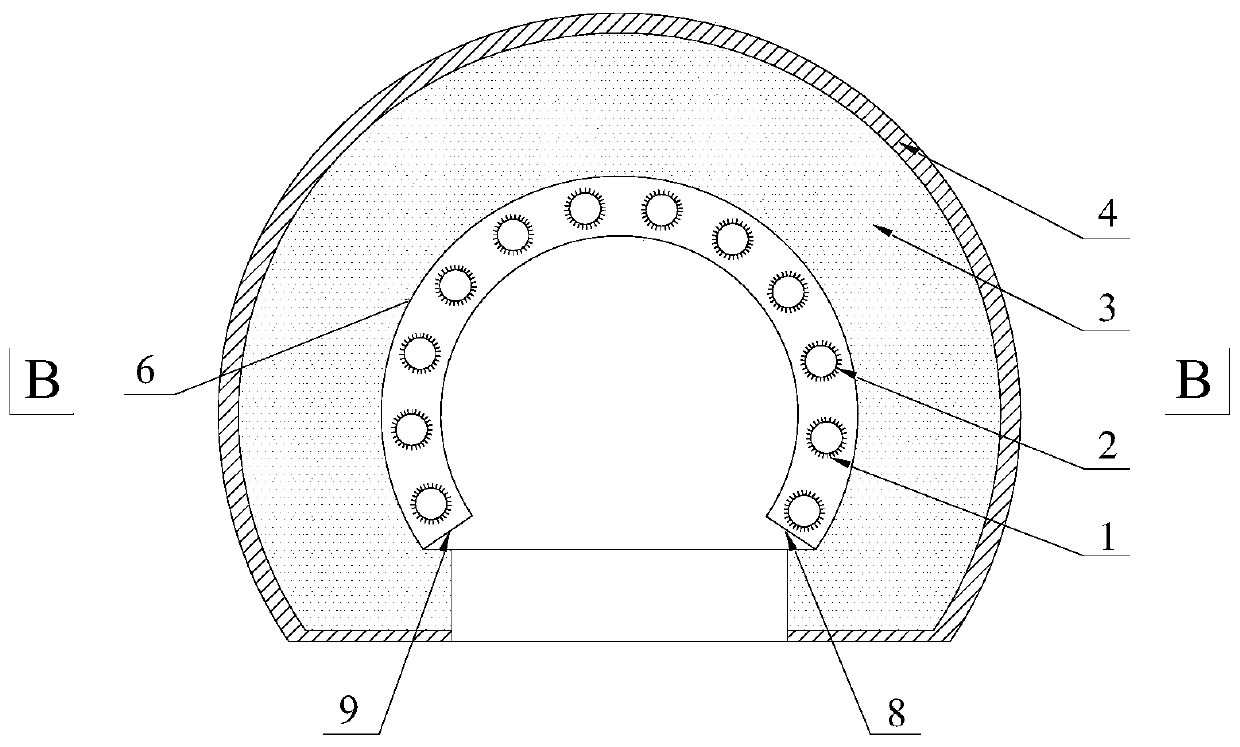

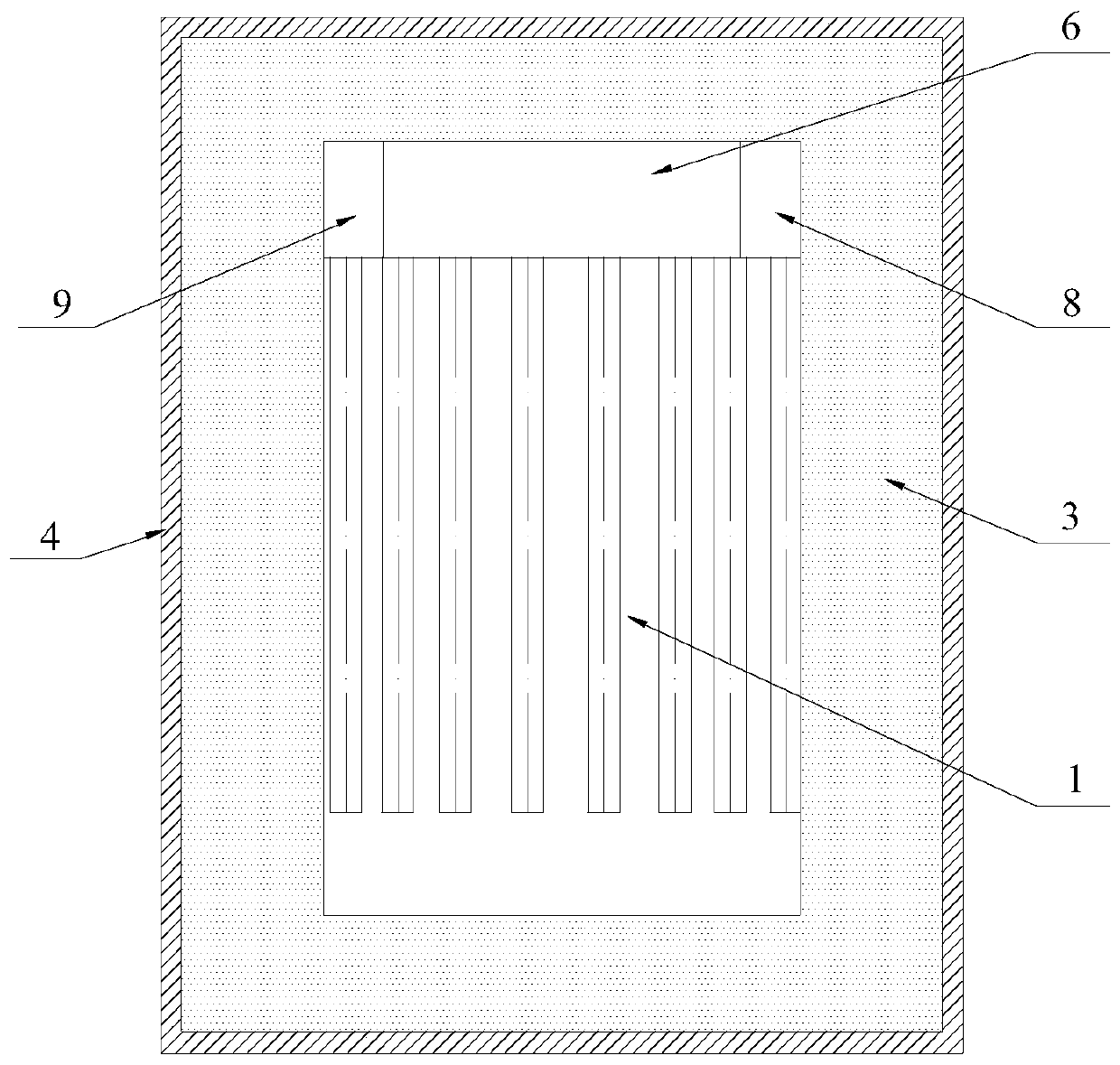

[0025] Such as Figure 1 to Figure 4 As shown, the present invention includes a high-temperature heat pipe 1. The high-temperature heat pipe 1 adopts a cylindrical long pipe with both ends closed to maintain a vacuum inside the pipe and avoid impurities in the air from adversely affecting the evaporation and condensation of the medium in the heat pipe. Each high-temperature heat pipe 1 works relatively independently, and the number of high-temperature heat pipes 1 in the receiver can be freely adjusted according to the capacity of the solar thermal power station, thereby adjusting the thermal power of the receiver so that the receiver can better adapt to the characteristics of the power station. The high-temperature heat pipe 1 is divided into upper and lower sections, the upper section is the exothermic section, and the lower section is the heat-absorbing section, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com