A kind of semiconductor structure and its manufacturing method

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as being easily affected by film thickness, unfavorable control of the processing window of key dimensions of the bottom, and achieve the effect of increasing the processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

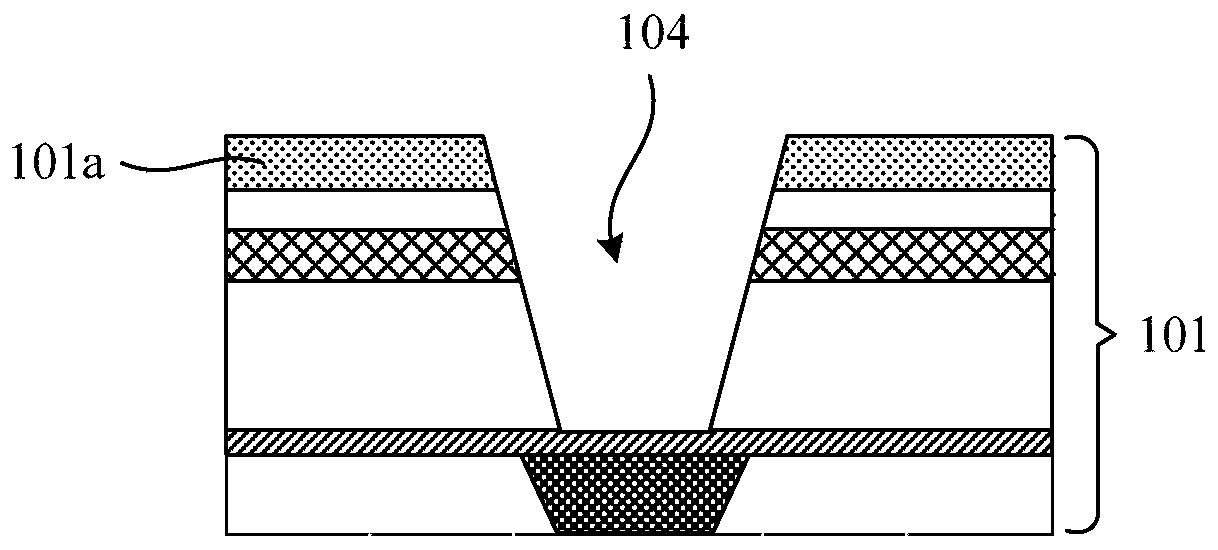

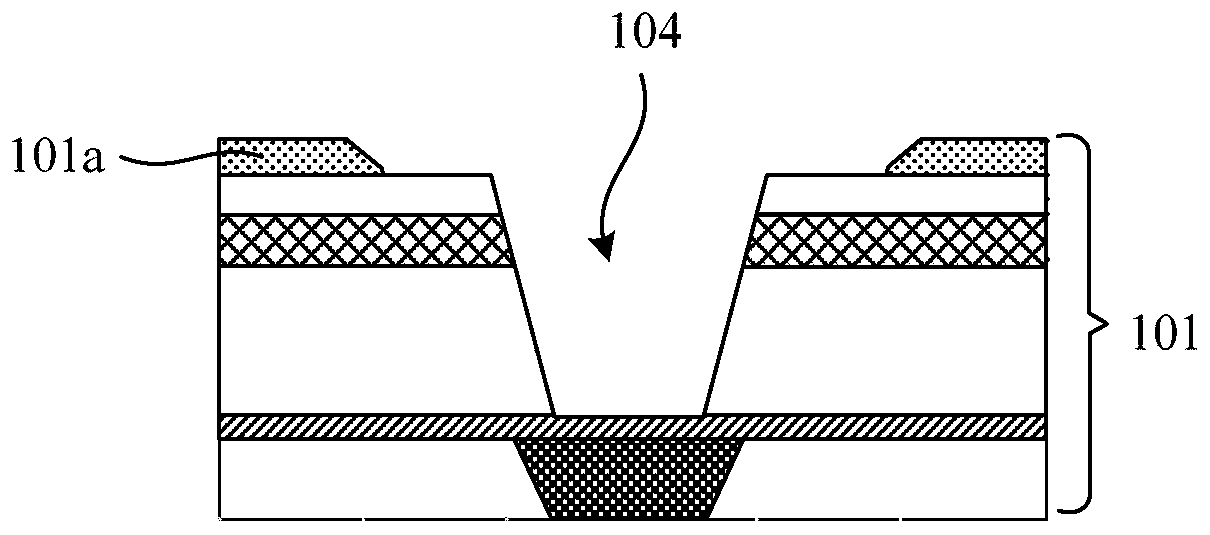

[0096] In this embodiment, a manufacturing method of a semiconductor structure is provided, please refer to Picture 9 , Shown as the process flow chart of the method, including the following steps:

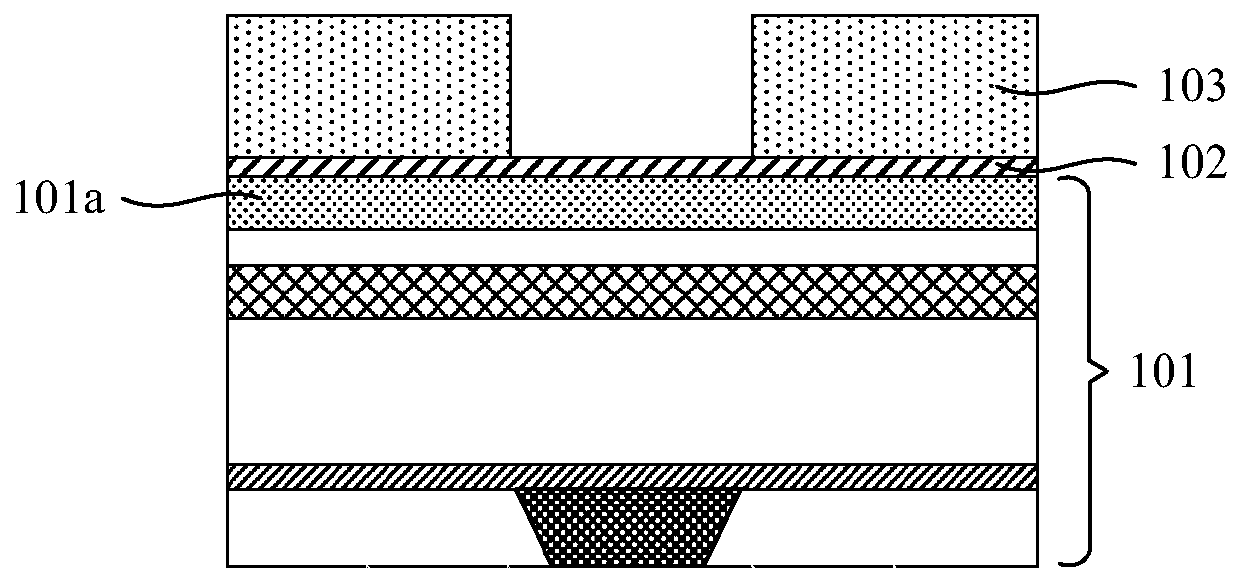

[0097] See Picture 10 , A layer stack structure 301 is provided, the layer stack structure includes an insulating dielectric interlayer 301a, an etching stop layer 301b located below the insulating dielectric interlayer 301a, and a first hard mask layer 301c located above the insulating dielectric interlayer 301a And a second hard mask layer 301d located above the first hard mask layer 301c. In this embodiment, an insulating layer 301e is further provided between the first hard mask layer 301c and the second hard mask layer 301d, and the material of the insulating layer 301e includes but is not limited to silicon dioxide. The layer stack structure 301 is further provided with a contact portion 301f, and the contact portion 301f is located under the etching stop layer 301b.

[0098] ...

Embodiment 2

[0115] The invention in this embodiment also provides a semiconductor structure, please refer to Figure 17 , Shown as a schematic diagram of the semiconductor structure, including a layer stack structure 401, a first recessed structure and a second recessed structure, wherein the layer stack structure 401 includes an insulating dielectric interlayer 401a, an etching located under the insulating dielectric interlayer 401a The barrier layer 401b, the hard mask layer 401c located above the insulating dielectric interlayer 401a, and the insulating layer 401d located above the hard mask layer 401c, the first recess structure 402 opens from the top surface of the insulating layer 401d, And extends downward into the insulating dielectric interlayer 401a, but does not penetrate the insulating dielectric interlayer 401a. The second recessed structure 403 opens from the bottom surface of the first recessed structure 402 and extends downwards through the etching For the barrier layer 401b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com