Method for forming dopant well and method for forming image sensor

An image sensor and deep doping technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of difficulty in controlling the increase of key dimensions, and achieve the effect of uniform key dimensions and simplified process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

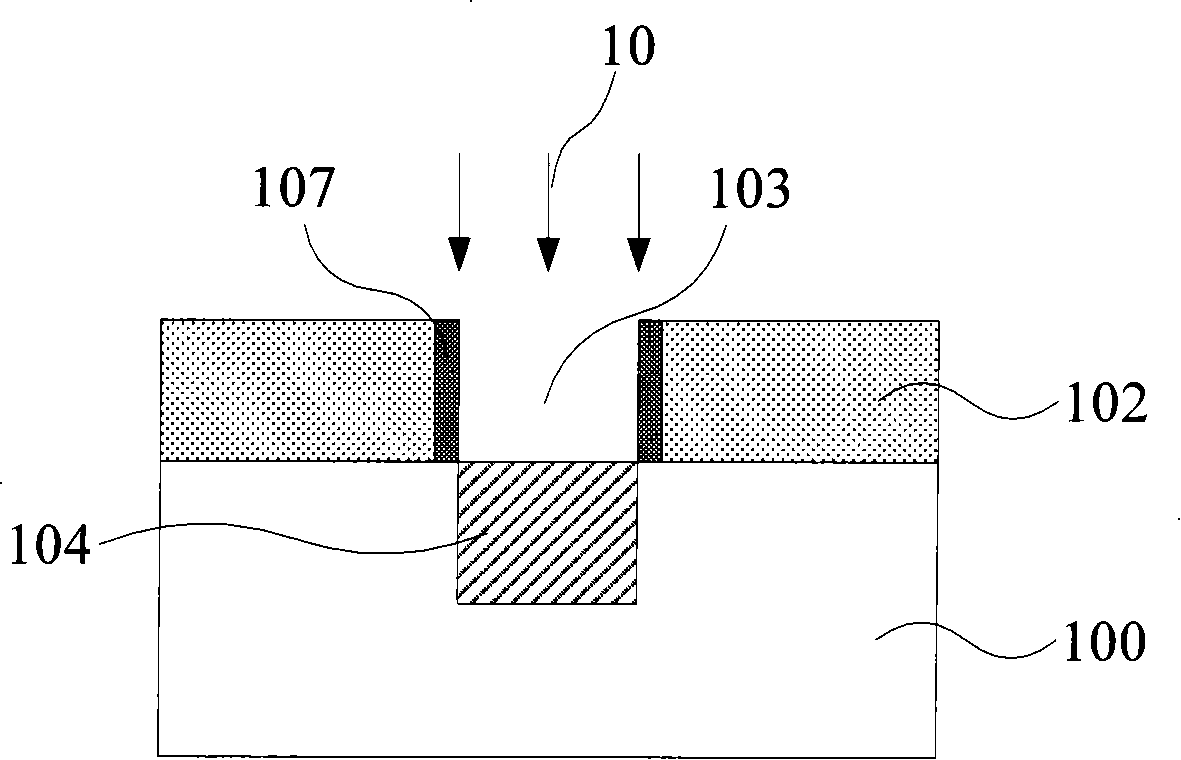

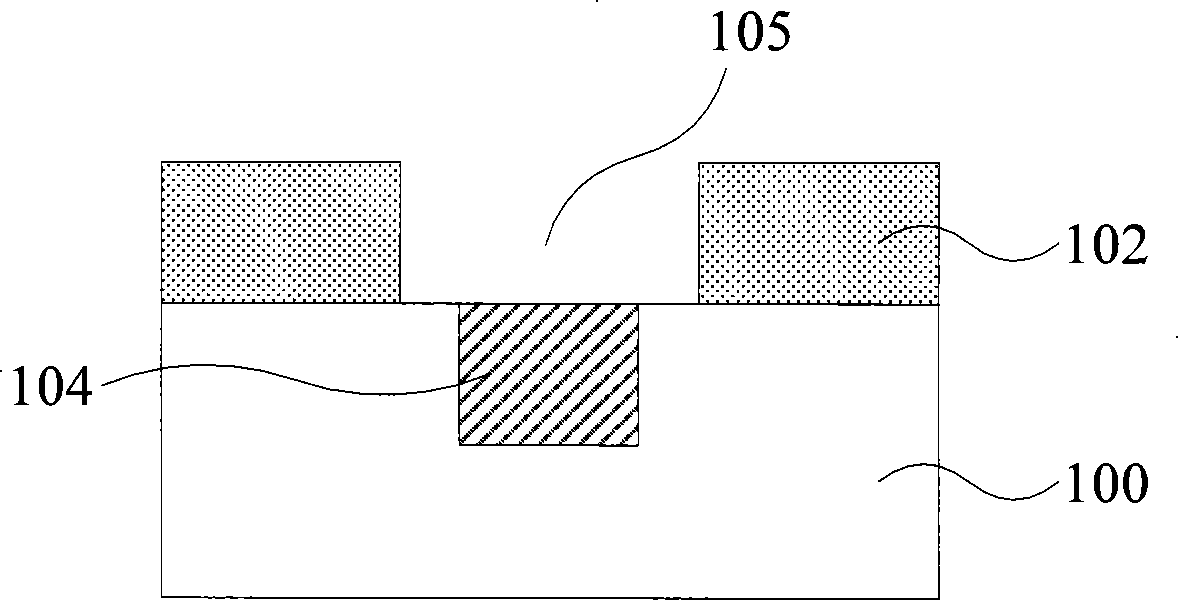

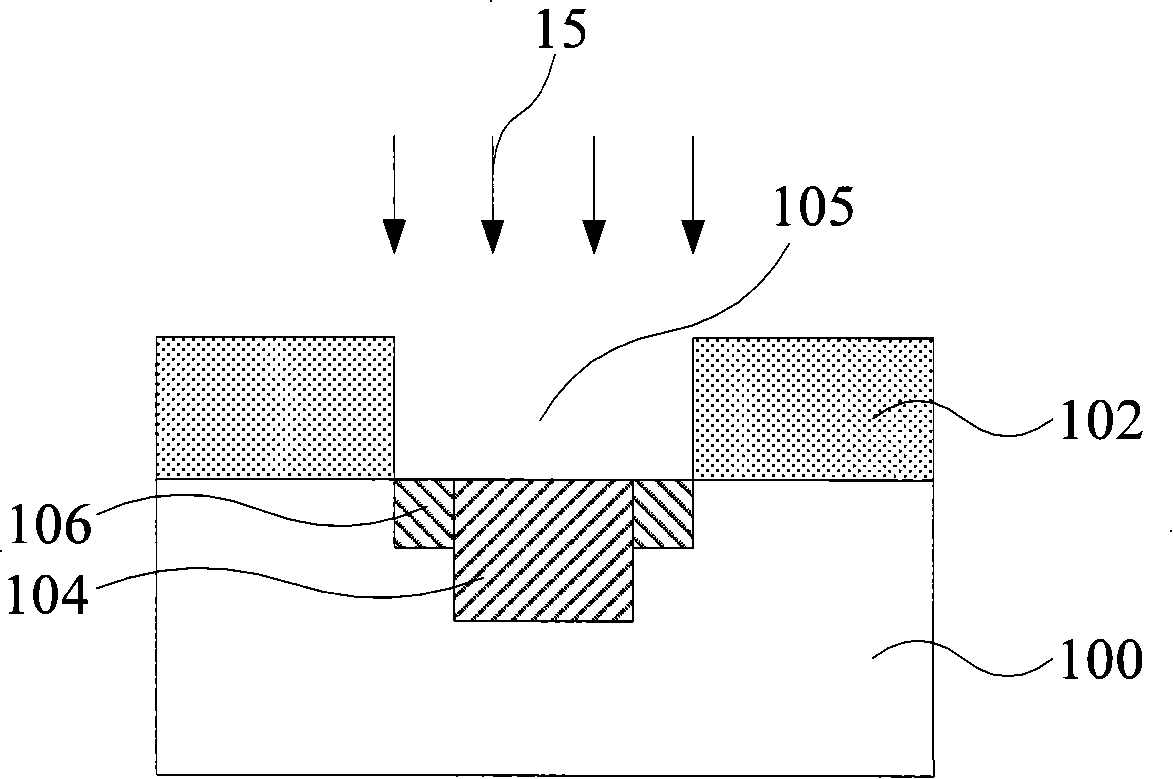

[0025] The invention etches the photoresist layer and the silicon oxide layer to expose the semiconductor substrate to define the doped well pattern; ash the photoresist layer to expose the silicon oxide layer to increase the critical dimension of the doped well pattern; The key dimensions of the doped well pattern are defined in advance, so they will not be affected by the implanted ions, and the key dimensions can be controlled uniformly. Furthermore, because only one ion implantation is required, a doped well with depth gradient distribution can be obtained, and the process steps are simplified.

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Figure 4 It is a flow chart of a specific embodiment of forming a depth gradient distribution doped well in the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com