Semiconductor storage device and preparation method thereof

A storage device and semiconductor technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve problems such as the inability to meet the resolution requirements of manufacturing micro-line width patterns or manufacturing process requirements, and achieves a reduction in size. The effect of small impedance and reduced preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The semiconductor storage device and its manufacturing method will be further described below with reference to the accompanying drawings and embodiments.

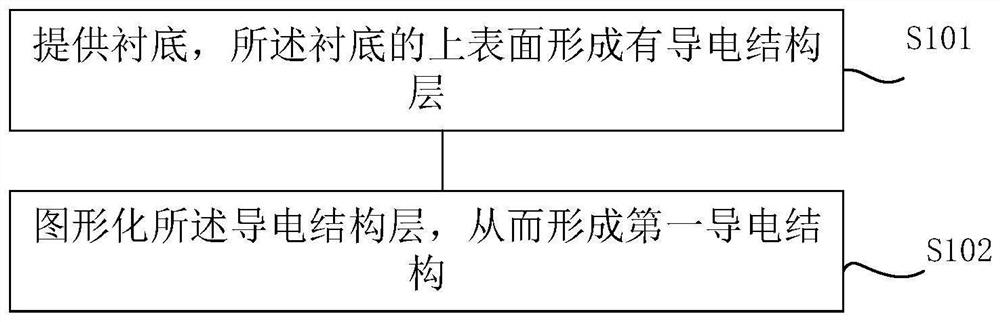

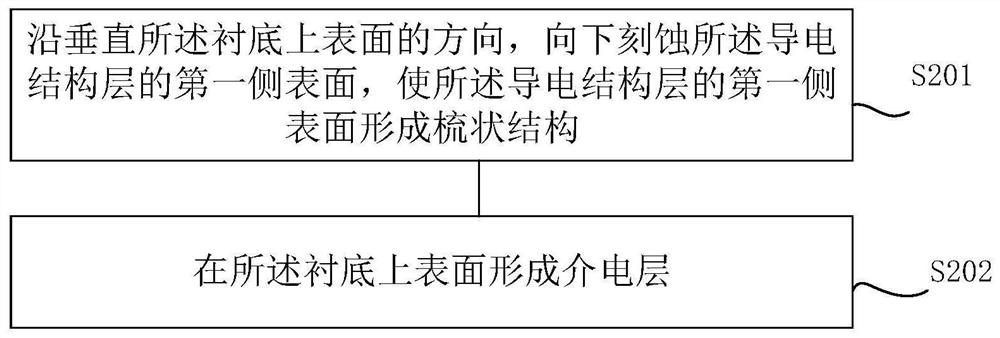

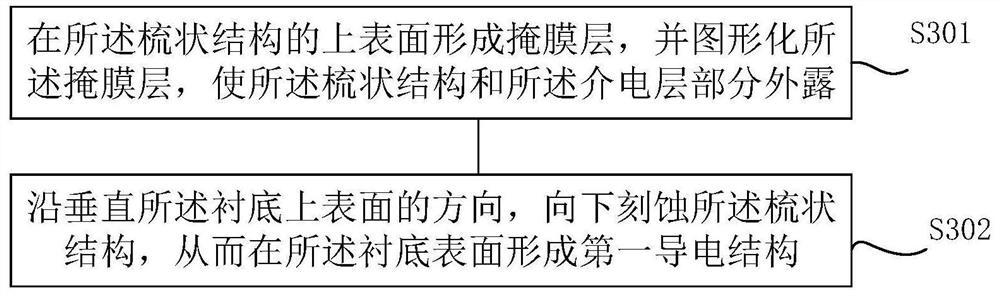

[0040] see figure 1 , is a schematic diagram of the steps of the method for manufacturing a semiconductor storage device in an embodiment of the present application.

[0041] In this embodiment, a method for manufacturing a semiconductor storage device provided by the present application includes the following steps:

[0042] Step S101 : providing a substrate 101 with a conductive structure layer formed on the upper surface of the substrate 101 . here as Figure 6 as shown, Figure 6 It is a schematic side view of the semiconductor storage device when the semiconductor storage device is prepared in an embodiment of the present application.

[0043] The substrate 101 includes a semiconductor base and several film layers formed on the surface of the semiconductor base.

[0044] The material of the semiconductor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com