A kind of formation method of high-k metal gate

A metal gate and formation layer technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of device reliability impact, increased risk of metal voids, and increased surface roughness of trenches, so as to increase critical dimensions, eliminate The effect of metal voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

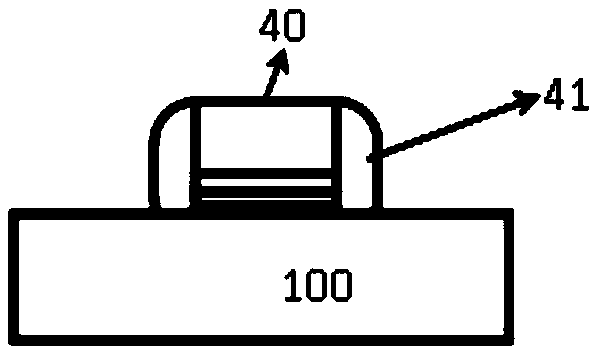

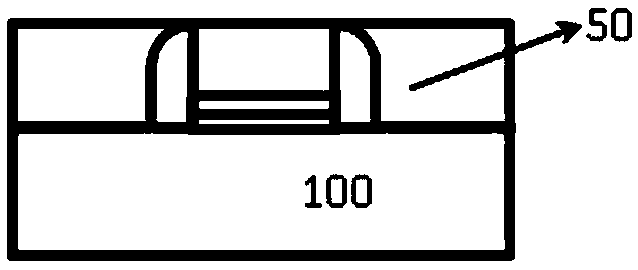

[0020] Figure 1 to Figure 6 Each step of the method for forming a high-K metal gate according to a preferred embodiment of the present invention is schematically shown.

[0021] Specifically, such as Figure 1 to Figure 6 As shown, the method for forming a high-K metal gate according to a preferred embodiment of the present invention includes:

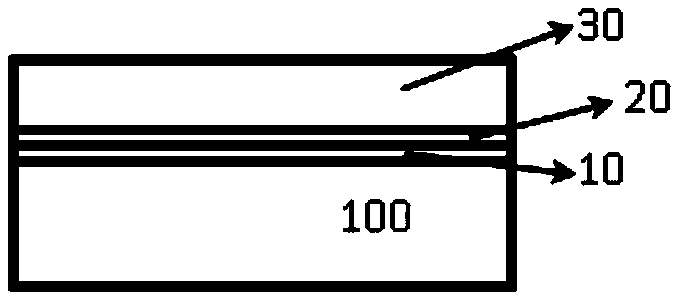

[0022] The first step: sequentially forming an interlayer dielectric layer 10, a TiO2 thin film layer 20 and a polysilicon layer 30 on a substrate 100;

[0023] Preferably, the interlayer dielectric layer 10 is a SiO2 film layer. Preferably, the growth method of the interlayer dielectric layer 10 may be chemical vapor deposition, atomic layer deposition, thermal oxidation, low-pressure chemical vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com